Bitumen Emulsion Lab Mill

All You Need to Know about Asphalt Emulsion Roof Coating ...

May 18, 2021 · What Is Asphalt Emulsion? Bentonite clay, water, and asphalt are emulsified using a colloid mill to make asphalt emulsion. The emulsifying process breaks down the molecule size and produces a stable, waterproof compound. Asphalt emulsion is .

Lab Mills and Lab Grinders | New and Used Lab Mills | LabX ...

Find new and used lab mills and grinders at LabX. Auctions, For Sale, Wanted ads. The first place to look for buying lab mills and grinders.

Bitumen emulsion

bitumen emulsion water stabilizer acid emulsifier colloid mill bitumen solvent emulsion colloid mill dwell tank heater stabilizer acid emulsifier water Inline emulsion plant Manufacture of bitumen emulsions Bitumen emulsions are usually made using a colloid mill, although other dispersion devices are possible. In the colloid

Alex Dannik

Asphalt Milling/Cold Mill/Cold Planing/Pavement Profiling/Asphalt Grinding/Road Resurfacing Road Builders Professional Group Bitumen Emulsion Lab Production and Testing

High Shear Homogenizer, Powder/Liquid Mixers, Bead Mill ...

Wahal Engineers is a leading manufacture and Exporter of Industrial Equipment High Shear Homogenizer Industrial Mixer, Multiprocessor, Bead Mill, Industrial Agitator, Liquid Powder Mixer, Bitumen Emulsion Plants, Food Processing Plants, Planetary Mixer, Lab Models, Polymerized Modified Bitumen .

(PDF) Bitumen emulsion Technical Bulletin | Research and ...

colloid mill dwell tank heater Bitumen emulsion can be produced either in for the quality of the emulsion and automatic or automatically controlled using flow meters for a batch or an inline process plant. The batch semiautomatic control will make the manu all material dosage except acid, which should process involves at least two process steps facturing more efficient and reduce human ...

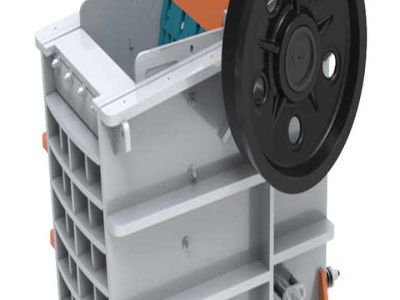

Bitumen Emulsion Production Colloid Mill

Bitumen Emulsion Production Colloid Mill. A colloid mill is a piece of equipment designed for grinding of substances to colloidally sized particles. Liquid medium is required for high quality. The first colloid mill example was constructed by K. Plausson in 1920. Since then, the milling machine has been much developed, and is actively used in ...

DenimoTech A/S: Bench laboratory colloid mill

Bench Laboratory Colloid Mill (BLM) Replies the production process. This portable scale lab replies the production process for preparation of bitumen emulsions, and a heated and insulated version replies production of Polymer Modified Bitumen. Designed just like the fullscale production mills, the rotor and stator system, coupled with ...

Hand Mill | FrackinUniverse Wiki | Fandom

The Hand Mill is your first tier extractor, created by using the Machining Table. They can be used to extract basic materials at a rather high are used to extract FU materials which are essential in creating machines and Gene Samples. Lists of Materials that can be extracted can be found here. However, the starting Hand Mill yields less than it says on the extractable item list ...

Laboratory Bitumen Emulsion Plant Uvb L Globecore – OhTheme

Oct 05, 2021 · Water bitumen laboratory system uvb l is designed: to prepare laboratory parties of bitumen emulsions; to develop the recipe of water bitumen emulsion depending upon the solution of bitumen emulsion components likewise the area of appliion. specifiions № parameters value 1. batch emulsion capacity, dm3 20 2. bitumen pressure, mpa 1,6 3. bitumen temperature, °С 140 160 .

Sweet Emulsion – How Asphalt and Water Combine – .

Milk is a type of emulsion. Asphalt Emulsion Production. To create an asphalt emulsion, the asphalt and water are blended by a colloid mill, which uses spinning discs to break the asphalt up into droplets so it can be dispersed into the water droplets may also end up inside the asphalt droplets, making this a "waterinoilinwater" or double emulsion.

Asphalt Emulsion

K. Takamura, A. James, in Advances in Asphalt Materials, 2015 Introduction. Asphalt emulsions are watercontinuous dispersions of fine asphalt droplets, typically 1–10 μm in diameter, manufactured with the aid of a colloid mill. The emulsions may contain between 40% and 80% asphalt by weight. The emulsions have significantly lower viscosity than asphalt itself, and so can be applied at ...

Bitumen Emulsion Production Equipment.

Bitumen emulsion plant model UVB1 with production capacity 1 m3/hour is applied for production of small quantities of bitumen emulsion. Compact design of bitumen emulsion plant allows easy installation and space saving. Bitumen emulsion plant is equipped with solvent pump; it allows to use low penetration grade bitumen to produce high quality ...

Bitumen Emulsion Plant

Bitumen Emulsion Plant. Leading Manufacturer of Industrial Bitumen Emulsion Plant, Bitumen Emulsion Machine, Bitumen Emulsion Plant, Frigmaires Bitumen Emulsion Machine, Colloid Mill for Bitumen and Bitumen Tank from Mumbai. Industrial Bitumen Emulsion Plant. Rs 16 Lakhs/ Piece.

Construction Products | Bitumen Products | Higgins | Higgins

Bitumen products Higgins is a leading supplier of bulk bitumen and other specialist bitumen products to Higgins and the wider industry. At Awatoto in Napier, Higgins operates a specialist polymer modifiion plant – converting bitumen into hot or emulsified products, ranging from general purpose emulsified bitumen to specialised spray seal ...

Planetary Ball Mill

Lab Sand Mill. Lab Rod Mill. Lab Rapid Ball Mill. Lab Glove Box / Operation Box. Centrifuge Series. Vibrating Screen Series. CONTACT. Tel: . Fax: . Mobile: . Email1: mills Planetary Ball Mill. Dual Planetary Ball Mill. Cryogenic Planetary Ball Mill . Vertical Planetary Ball Mill for Glove Box Use. Heavyduty Fulldirectional ...

An Introduction to Bitumen Emulsions

May 13, 2020 · Consequently, a bitumen emulsion is prepared by separately metering the heated asphalt cement, water, surfactant and other components into a colloid mill at preset temperatures and rates. The size of the asphalt particles and the quantity of surfactant affects the physical and chemical properties of the finished emulsion.

Bitumen Emulsion Plant

This video explains the working of bitumen emulsion plant used for manufacturing of both ionic and anionic emulsions. The fully automated system delivers ...

Bls Stainless Steel Laboratory Bitumen Emulsion Colloid Mill

BLS stainless steel laboratory bitumen emulsion colloid mill bitumen homoginizer colloid mill Principle of laboratory bitumen emulsion colloid mill : The basic working principle of colloid mill is shearing, grinding as well as highspeed stirring applied force, grinding is finished depending on the relative movement of toothform slope, one of them rotates at high speed, while the other stays ...

Colloid Mills | Colloid Mill Manufacturer | Sonic Corp USA

Colloid Mills are your best answer for particle deagglomeration and primary particle size reduction. Sonic's RotoMill rotors and stators are designed with a patented and proven multiangular system to provide superior shearing and grinding. There are 3 shear points that subject material to a higher degree of grinding than conventional mills.

Bitumen Emulsion

Advantages and Limitations of Bitumen Emulsion Advantages and Uses of Bitumen Emulsions are: Bitumen emulsion are used extensively in bituminous road construction. Other than this they are used for maintenance and repair work. Emulsions can be used in wet weather even if it is raining. Is ecofriendly as it is water based.

Tube Mill 100 control

The Tube Mill 100 control accommodates larger grinding chambers with a maximum volume of 100 ml (MT 100) . The grinding chamber and cover are made of a transparent material so grinding tests can be observed at any time. The mill can be used for hard (Mohs hardness up to 5), dry and brittle materials. It is especially suitable for grinding seeds, such as corn and wheat. The mill will only start ...

Latest Posts

- تستخدم مطحنة الكرة الأسعار في الهند

- باكستان مطحنة الكرة الصانع

- الذهب طاحونة القديمة

- المطرقة محطم المخططات والمواصفات

- طاحونة الحلقة

- كسارة الفك خام للبيع في ماليزيا

- لاوس تأثير محطم للبيع

- بيع حجر محطم الخزف

- لقط من مخروط محطم

- مصنع الجبس للبيع

- المعادن والخامات الحديدية والسبائك الحديدية

- الإنتاج السنوي من خام النحاس

- الهندي نهر الرمال حفار

- 48 الروتاري مخروط محطم الألغام

- Stone Crusher For Brick Machine Manufactured In Coimbatore

- Crusher Sand Dust Is Code

- Charcoal Grey Granite Chippings

- Catalytic Converter Recycling Crusher Machine

- Machines Take Copper From Ore

- Vertical Roller Mill For Cement Factory Process Flow Stone

- Ball And Vertical Mill

- Roll Crusher For E Panded Clay

- Flotation Of Silica From Bau Ite Ore

- Pabrik Mesin Pengolahaan Emas

- Lego Exo Force Building Instructions Of Iron Crusher

- Rubber Conveyor Belts Company

- Ac Motor Untuk Stone Crusher Pasir Membuat Batu Quarry

- Penjualan Alat Mesin Semprot Tanaman Di Medan

- Stone Aggregates Machines Prices In Britain

- Cuisinart Supreme Grind Automatic Burr Mill Dbm 8