Small Steel Rerolling Mill

Project Report on steel rolling mill from scrap and sponge ...

Detailed Project Report (DPR) on steel rolling mill from scrap and sponge iron Present Market Position and Expected Future Demand, Technology, Manufacturing Process, Investment Opportunity, Plant Economics and Project Financials. comprehensive analysis from industry covering detailed reporting and evaluates the position of the industry by providing insights to the SWOT analysis of the .

Metal Rolling and Drawing

The rolling mill shown in Figure is especially designed for the small workshop. The rolling mill frame consists of four round pillars which connect the upper and lower end plates together. The bearings in which the roller's arbors rotate can travel vertically on the polished guide columns. The rolls are 45 mm in diameter and 90 mm wide.

The Rani ReRolling Mills Ltd.| Best Steel Rod company ...

Being a developmentdriven company,"The Rani ReRolling Mills Ltd.", the steel manufacturing wing of RRM GROUP is characterized by its ability to create and develop steel industry opportunities. From the establishment period since last 25 years, RRM is optimizing its operations through quality based management and implementing new technologies.

Kamran Steel – Shaping the Future

Kamran Steel has been in the steel industry for more than 3 decades. We started as steel traders and soon established a solid footing by a partnership with Senior Steel in 1984. Our company consists of a stateoftheart fully automated rolling mill with a production capacity up to 25 tonnes per hour.

» The art of recycling used train tracks

May 15, 1998 · A rerolling mill is an extremely hostile environment for bearings, especially at the intermediate and finishing end of the mill, where the steel starts to cool rapidly. "At the intermediate end, the steel is at about 1,850 degrees F," said Keister. In this appliion, there are loads in excess of 50,000 kilograms and speeds of up to 300 rpm.

Steel Rolling Mill Machine: Hot Rolling Roll

Apr 13, 2021 · At present, there is a trend of using bucket steel rolls to replace forged steel rolls. The roll of the 6VH billet continuous rolling mill in the Baosteel blooming mill is made of forged semisteel and forged cast iron with % ~ % C, which has good wear resistance and poor hot crack resistance.

Newly designed rebar rolling mill from Primetals ...

Dec 03, 2015 · The mill was erected in the Jalna plant in the state of Maharashtra and produces about 250,000 metric tons of rebar per year from lowcarbon steels. Primetals Technologies specifically developed this plant design for small to mediumsize production capacities. It allows projects to be implemented comparatively quickly and economically.

Shree Parasnath ReRolling Mills

Welcome to Paras Steel. The modern plant incorporates a complete thermax treatment system and a structural mill. The Complete range of requirements can therefore be met under one roof. Durgapur being one of india's premiere steel hubs, the billets are locally procured from Steel Authority of India. Proximity to other raw meterials and markets ...

Steel Rolling Mill Machine: Hot Rolling VS Cold Rolling

Feb 19, 2021 · The rolling of steel is mainly hot rolling, and cold rolling is only used to produce small section steel and thin plate. Hot Rolling. Advantages: It can destroy the casting structure of ingot, refine the grain size of steel and eliminate the defects of microstructure so that the structure of steel is compact and the mechanical properties are ...

ZAK ReRolling Mills (Pvt) Ltd

ZAK ReRolling Mills. ZAK ReRolling Mills has revolutionized the steelmaking industry with its stateoftheart manufacturing practices, and become one of the leading steel manufacturers in RawalpindiIslamabad region in a very short span of time.

Metal Rolling

In a metal rolling process, rolls, stands, bearings, housing, motors, and other mechanical equipment are all a necessary part of the manufacturing operation. The place where all the equipment for metal rolling manufacture is set up is called a rolling mill. Rolling mills often .

steel rerolling mill prefeasibility

Steel re rolling mill, spread on 12 acres of land is available for sale in Coimbatore, Tamil Nadu. The rerolling mill and melting unit both are in good running condition and are for sale. The mill is 16 inch and has fully automatic machines. There is also a cooling plant. The mill.

BANGLADESH STEEL REROLLING MILLS LIMITED Company .

BANGLADESH STEEL REROLLING MILLS LIMITED is loed in Chattogram, Chittagong, Bangladesh and is part of the Foundries Industry. BANGLADESH STEEL REROLLING MILLS LIMITED has 1,046 total employees across all of its loions and generates million in sales (USD).

Mughal Steel

Mar 15, 2016 · ReRolling. The versatile mills at MISIL provides excellent shape and size control for a variety of product sections. These include; Medium Section Mills, Tandem Section Mills, Small Section Mills and Bar rerolling mills. The billets cannot be used commercially till rolled to acquire desired shapes and products.

Steel ReRollingTechnology, Machinery, Plant, Patent ...

A small re rolling mill came out into a vastly expanding market. As a re roll mill they had to purchase their steel in a semi finished state from other domestic mills. The strong demand for steel naturally dictated that these mills use their own capacity rather than sell it to a competitor.

Steel Rolling Mill

(India) Pvt. Ltd. Tirumala ReRolling Pvt. Ltd. Torus India Ltd. Transpower Engineering Ltd. Trichy Steel Rolling Mills Ltd. Trident Steels Ltd. Tulsyan N E C Ltd. Tungabhadra Steel Products Ltd. U B L Industries Investments Ltd. Unique Intercontinental Ltd. Unique Structures Towers Ltd. Unison Metals Ltd. Upper India Steel Mfg. Engg. Co ...

Starting Steel Mini Mill

A steel mill operation is at high risk for health hazard accidents. Because of this, you may also want to visit the department of health as well to inquire. Similar Articles. Requirements in Setting up Recycling Plant; How to Start a Steel Business; Get adequate space. Scout a loion that has enough space for your steel mill operations.

AlHadeed ReRolling Mills

AlHadeed ReRolling Mills, Karachi, Pakistan. 519 likes · 5 talking about this. Manufecturer of MS Steel BAR of Different sizes using ship plate as raw material..

Part of the Rolling Mill Equipment

1. The work machine seat. It is composed of the roll, rolling mill arch, bearing package, bearing, worktable, rolling guide, roll seat, roll adjusting device, upper roll balancing device and roll changing device. 2. Rolling mill roll/roll bearing. The roller is the part that makes the metal plastic deformation.

Latest Posts

- السعودية صامت كسارات الخرسانة

- الألمانية مطحنة الكرة الجافة

- عملية تصنيع الطين محطم

- تستخدم آلات التعدين المبيعات companies in السويد

- نتائج الحشو محطم

- قائمة تكاليف كسارة الحجر الصغيرة في الهند

- محجر الحجر CS

- متدرج الحجر صور

- في نهاية المطاف محتوى الماء من غسل الرمال

- آلة تصنيع أكسيد المنغنيز

- بيتمان الذهب محطم

- كيفية تصميم بالاهتزاز الطاعم

- مسح إجمالي إنتاج سحق

- مصنع مطحنة البنتونايت الهندي

- Horizantal Cement Mill Parts

- Mobile Crawler Crusher

- Where Gold Ore Processed In Canada

- Iron Ore Beneficiation By Gravity

- Cornerstone Glacier Gravel Plant With Primary Crusher

- Can A Rolls Crusher Crush Foundry Sand

- Sheet Metal Machine Brazil

- Grinding Machine For Barite

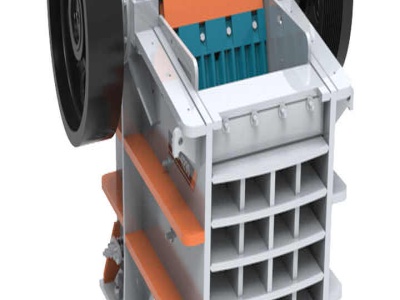

- Crusher Gator Portable Jaw Crusher

- Kptco Kpt Mm P Grinder Price

- Industrial Vibratory Conveyor System For Hot Petcoke

- Valve Grinding Machine In Seychelles Pakistan For Sale

- Kailash 3 Stone Wet Grinder Reviews

- Crushing And Screening Rothery And Mellor The Institute Of Quarrying

- How Many Cubic Meters Of Sand Can Be Processed In 1 Ton Of Stone

- Small Scale Mining Rock Crushers For Sale