Grinding Process Property

Development of Multigrit cBN Grinding Wheel for ...

A series of grinding trails have been used to correlate the grit properties with the grinding performance. The two evaluated grit characteristics are newly proposed aspect ratio (𝐴 ) and the concentration in the grinding wheel. The results show that blockier particles (lower𝐴 ) generate high forces and lower grinding wheel wear. On the other hand, the elongated particles require less ...

GRINDING FEEDS AND SPEEDS

Process Variables and their Effect on Grinding Wheel Performance Grinding wheel recommendations, unless prepared for specific cases, are predied on conditions which may be considered as average. Deviations from such basic conditions will generally affect the manner in .

Investigation on the grinding properties of high thermal ...

· Tsai et al. studied grinding property and lifespan of grinding wheel under graphite being infiltrated into grinding wheel . The results showed that the grinding temperature, grinding force, and wheel wear were all reduced during the grinding process. Wu et al. studied the effect of slotted cubic boron nitride grinding wheels on the surface damage of highly efficient and lowdamage grinding ...

Roasting, Grinding, and Storage Impact on Thermodynamic ...

· Samples were then stored at polypropylene bags and kept at biochemical oxygen demand type chambers in two storage temperatures (10 and 30C). These were analyzed at 0, 30, 60, 120, and 180 days, regarding water content and water activity. Mathematical modeling and thermodynamic properties of coffee moisture adsorption process were accomplished.

5 Benefits to InHouse Grinding | Production Machining

· Providing inhouse grinding is a benefit to both the machine shop doing the grinding as well as its customers. The inhouse process saves time and money, and helps a shop create higher quality parts. Ripley Machine and Tool Inc. (Ripley, New York), has had inhouse grinding

Influence of Dry Grinding On PhysicochemiCal and Surface ...

grinding process (Wu et al., 1996; Liao and Senna, 1992; Yekeler et al., 2004). ... Equipment and grinding medium properties of vibrating ball mill and grinding parameters for talc Properties Values Chamber volume (cm3) 500 Vibration amplitude (mm) 06 Vibration intensity (rpm) 1500 Grinding period (min) 5150 Ball diameter (mm) 1314 Ball density (g/cm3) Ball charge (%) 80 Density (g/cm3 ...

Processes | Free FullText | Drying Kinetics, Grinding ...

In this study, we studied the drying process, grinding characteristics and physicochemical characteristics of broccoli sprouts (BS). The seeds of broccoli were germinated at 20 °C for 3 and 6 days. Then, the seeds were air and freezedried, and the Page model was used for prediction of drying kinetics of broccoli sprouts. It was observed that the drying time of BS decreased about twofold as ...

White paper, June 2015 Advanced process control for ...

ore properties, production targets and management priorities. 2 White paper | Advanced process control for grinding circuits Abstract Recent copper price evolution pushes modern mining industry even harder to achieve highest production with maximum efficiency. Operations are bound by numerous contractual and environmental conditions that bring a high degree of complexity to both the operators ...

purpose of grinding processs

Purpose Of Grinding Processs karishmasteel. Purpose Of Grinding Processs. automatic control mechanism for grinding process based on,first, frequency converter regulators into first grinding machine ore amount, and the energysaving purpose come true. in the whole process of dressing and grinding, the main control to mine is mineral feeding control and mineral grinding machine's mineral ...

Manufacturing Processes 2: Grinding, Honing, Lapping ...

· Manufacturing Processes 2: Grinding, Honing, Lapping. Manufacturing Processes 2. : The future of manufacturing companies depends largely on their ability to adapt to swiftly changing global conditions. These are exemplified by international com tition, rapidly growing intercommuniion and the increased significance of en ronmental issues ...

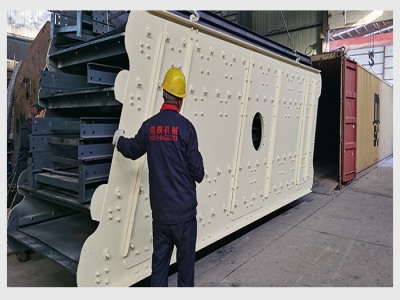

Milling Grinding | Process Technology | Contact us

Parts of the product that become fine enough during the process leave the grinding chamber through the sifting screen plate. The particle size of the milled product is determined by the speed of the hammers and size of the mesh openings in the screen plate. In many production processes, a welldefined particle size is essential, for achieving the correct level of feed conversion or ...

Revasum | Semiconductor Grinding Technology

Revasum specializes in the design and manufacturing of capital equipment used in the semiconductor device manufacturing process. Our product portfolio includes grinding, polishing and CMP equipment used to manufacture substrates and devices for the global semiconductor industry. The Company has leveraged its significant intellectual property ...

8 Answers to the Most Frequently Asked Questions About ...

THROUGHFEED CENTERLESS GRINDING. During this process, the axial traverse movement is imparted from regulating wheel to the work, because the axis and grinding wheel is inclined at a small angle α1 or because the work rest at an inclination angle of α1. The peripheral speed vp is resolved into the circumferential speed of the workpiece vw and the workpiece speed vtr (mm/min) of which are ...

Lee's Grinding Inc.

From our experience in working with demanding customers on difficult grinding appliions, Lee's Grinding has developed valuable inhouse expertise on which you can rely. We encourage you to contact us in the beginning stages of your product development. Often, grinding is the most critical process. If a part is improperly prepared for the grinding phase, you could suffer cost overruns and ...

grinding

This may be attributed partly to a faulty grinding process with negative effects on the surface zones and the surface properties. 39 Gear Grinding Techniques Parallel Axes Gears (March/April 1985) The fundamental purpose of gear grinding is to consistently and economically produce "hard" or "soft" gear tooth elements within the accuracy required by the gear functions. These gear elements ...

Wafer Back Grinding Tapes

Strong adhesion to wafer with hydrophobic property to prevent water seepage for stable consistent backgrinding; Consistent bond strength during grinding process; Withstands high temperature and maintains high temperature peel strength; OnDemand ease to peel release upon UV exposure; Proven for wafer, panel of modules, glass and other substrate ; Adhesivecompliant buffer layer of 500 micron ...

Grinding Size Estimation and Beneficiation Studies Based ...

GRINDING SIZE ESTIMATION AND BENEFICIATION STUDIES BASED ON SIMPLE PROPERTIES OF ORE COMPONENTS A. Ekrem YUCE Istanbul Technical University, Faculty of Mines, Mineral Processing Engineering Department, 34469, Maslak, Istanbul, Turkey. Visiting Scholar at Mining and Metallurgical Engineering Department, UNR, Reno, Nevada, USA,

Grinding stone, process for its production and grinding ...

· Grinding stone, process for its production and grinding method employing it . United States Patent Appliion . Kind Code: A1 . Abstract: A grinding stone using a metal material as the main material of a bonding material, which comprises: (A) abrasive grains of at least one member selected from the group consisting of diamond, cubic boron nitride, silicon carbide and .

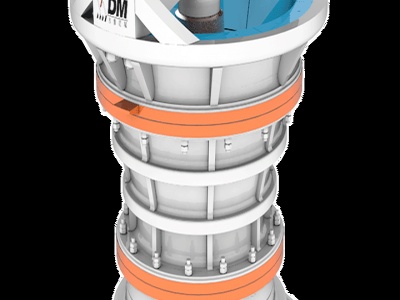

SiC Wafer Grinding

Silicon Carbide Wafer Grinding. The EVG250/300 series Vertical Grinding Machine combined with Engis MAD Grinding Wheels can achieve a superior surface finish on silicon carbide wafers to reduce or even eliminate loose abrasive lapping steps. The machine can be customized to your needs: Auto dressing. In process thickness measurement.

Grinding process management

Inhouse grinding knowledge secured. Grinding Process Management . Get a grip on your grinding processes and know what is needed for process optimization. We detect the possible causes of grinding burn and other process flaws before they happen. As grinding process experts, we know what works best, but also where things can go wrong. Based on an indepth analysis of your process .

Grinding Size Estimation and Beneficiation Studies Based ...

mineral properties and overgrinding of materials. Both cases consume significant excess energy and valuable mineral losses in slime fractions. This is due to the incomplete basic predetermination of the ore characteristics. In order to overcome undesirable aspects of processes, several basic preinvestigations for raw materials characteristics should be completed before the beginning of the ...

Latest Posts

- البلاستيك كسارة الرئيسية

- ما هو سعر كبريتات الكالسيوم الطبيعي في الهند

- سور الصين العظيم مطحنة مصنع الغسيل

- طحن جزيئات بلاستيكية صغيرة جدا

- إندونيسيا شيفرون الحزام

- الحجر الجيري كسارة متنقلة

- تصنيع السيور الناقلة في نقل المعادن

- الفلبين محطة توليد الكهرباء التي تعمل بالفحم

- شاكر الصانع جنوب أفريقيا

- كسارة الفك الناتج سيدة ملم

- الكروم دوامة مصنع للإيجار

- أفضل صانع كسارة الفك

- الفلبين ماكينات الجرانيت

- سحق أجزاء مطحنة الفحم

- أسود الكربون الصخر الزيتي و تعدين الذهب

- Coal Crusher Capacity Tph

- Used Vehicle Crusher And Compactor

- Various Impact Crusher Pf

- China Cement Mill Suppliers Exporters In Uae

- Marketing Kaolin Silica Sand

- South American Aggregate And Quarry News

- Ball Mill Cement Pdf

- Latest Technology In Stone Jaw Crushers Sand Making Stone Quarry

- Mobile Primary Crusher Machinery In Sao Tome And Principe

- The Impact Of Discovery Of Gold Mines On The South African

- Rock Crusher False Business

- What Is Hand Mill Made From Ston

- Crusher Dry Grinding Eirich

- Gangue Production Equipment Pictures

- Indasa Dust Extraction Hand Sanding Blocks Vinnybyrne