Clinker Grinding Ball Mills

clinker grinding mills france

Clinker Grinding Mills New Technology. clinker grinding mills new design and analysis of ball mill inlet chute for roller press circuit in, clinker grinding mills new clinker grinding production (internal benchmark, cost of the . more details; Chapter 93.

Grinding Clinker Grinding Mill Manufacturer In Indonesia

Method For Grinding Of Material Especially Raw Material. Oct 23, 2019 22 43 57 A method of grinding material, in particular a raw material mixture for firing clinker in mills, in particular ball mills, in a tubular ball mill with or without discharge andor in a vertical mill, in circulation andor in a grinding circuit by separating fine gravel, socalled semolina ...

Ball Mill Manufacturers for Cement Plant in India

These ball mills are used to grind materials into extremely fine powder. Our ball mills are perfect for cement plants. Three types of ball Mills we re manufacturing: – 1. Raw materials mill 2. Cement (Clinker) mill 3. Coal mill. Uses / Appliions / Features : Reasonable design and strict manufacture . Strong to grind . Better the ...

Ball Mill

Manufacturer of Ball Mill Clinker Grinding Ball Mill, Ball Mills, Cement Ball Mill and Shoe Slide Ball Mill offered by Chanderpur Works Private Limited, Yamuna Nagar, Haryana.

rotating ball mill for clinker

rotating ball mill for clinker MathsDom EureetLoir. Industrial cement ball mills consist of a rotating dualchamber cylinder sized up to 8 Most of the earlier work on modeling of clinker grinding was The FL ball mill is a reliable choice for grinding cement clinker, gypsum As the crushing compartments rotate, the balls inside them grind the clinker.

China Mining Grinding Ball Mill for Ore, Cement Clinker ...

Mining Grinding Ball Mill for Ore, Cement Clinker Ball mill appliion: Ball Mill is a key equipment to grind all kinds of ores and other materials. Which is widely used in powdermaking production line including cement, silie, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal ...

ball mill grinding clinker and slag

Ball mill grinding clinker and slag ball mill grinding clinker and slag a ball mill a type of grinder is a cylindrical device used in grinding or mixing materials like ores chemicals ceramic raw materials and mills rotate around a horizontal axis partially filled with the .

DESIGN AND ANALYSIS OF BALL MILL INLET CHUTE FOR ROLLER ...

(Unidan Mill S) type FLS Ball mill which are used in the Cement industry for grinding clinker material. The present mill inlet chute can be used for the two compartment ball mills only in which primary and finish grinding both are takes place. It may be a closed or open circuit grinding systems.

Cost Of Ball Mill For Clinker Grinding Mills Plant

Cement mill Wikipedia. A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementMost cement is currently ground in ball mills and also vertical roller mills which are more effective than ball millsThe clinker plant comprises of feed pre crusher, feed hopper, table feeders, ball ...

Effect of High Pressure Grinding Rolls (HPGR) pregrinding ...

01/06/2016 · High pressure grinding rolls (roller presses) are used in both cement raw materials (limestone, clay, shale etc.) and cement grinding stages. The energy consumption is – kW h/t and about 10 kW h/t when recycling of the material is HPGR consumes 30–50% less specific energy as compared to a ball mill which indies higher comminution efficiency for a HPGR.

ball mill for clinker grinding

Grinding Mills 911Metallurgist. Concavex grinding medium is an improved type of ball grinding media which offers more surface area per unit of weight, and has found extensive use in the grinding of cement clinker The advantage of Concavex medium is its ability to increase mill capacity because of its interlocking shape and increased density per cubic foot of grinding charge Surface areas for ...

Some tests on the grinding of cement clinker with a ...

perimental stage of milling as applied to cement clinker. Ball mills . and . pebble mills have been used in a number of plants. ~hie . mill in its simplest conception consists of a cylinder revolTing around a horizontal axis with die plates arourid the circumference. ~he . grinding is done by steel balls. ~he . die ring is composed of

Cement Mill,Cement Clinker Grinding Plant

Cement Mill Overview. A cement mill is the equipment that used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills. Cement clinker is usually ground using a cement ball mill. This is essentially a large rotating drum containing grinding media normally steel balls.

Grinding Of Clinker In Ball Mill In Pdf

Cement mill Wikipedia. A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball Grinding, selecting (calculate) the correct or optimum ball size that allows ...

Ball Mills

Ball mills. The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1– times the shell diameter ( Figure ). The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight.

Grinding Mills

Concavex grinding medium is an improved type of ball grinding media which offers more surface area per unit of weight, and has found extensive use in the grinding of cement clinker. The advantage of Concavex medium is its ability to increase mill capacity because of its interlocking shape and increased density per cubic foot of grinding charge.

Effect of chemical composition of clinker on grinding ...

Grinding with increasing alumina (Al2O3) and iron oxide (Fe2O3) was carried out in a laboratory ball mill with 20kg capacity. contents. A high C3S content results in increased grindabil Size distribution of the mill charge is given in Table 2.

Matrix model of the grinding process of cement clinker in ...

Matrix model of the grinding process of cement clinker in the ball mill. Sharapov, Rashid R. Abstract. In the article attention is paid to improving the efficiency of production of fine powders, in particular Portland cement clinker. The questions of Portland cement clinker grinding in closed circuit ball mills.

Clay Crusher Cement Factory For Clinker Mixing | Crusher ...

Portland cement clinker is the essential ingredient . ball clay crusher . grinding or by separate grinding of slag and cement clinker with subsequent mixing. cost of cement in clinker factory – Crusher|Granite Crusher .

clinker grinding ball mill 206

Online monitoring and control of particle size in the. of ball mill to use of vertical roller mill (VRM) for clinker grinding. This change, from largely used ball mills towards vertical roller mills is mainly due to certain advantages offered by VRMs over ball mills such as: drying, grinding and classi fiion operations carried out in a single equipment, lower energy consumption ...

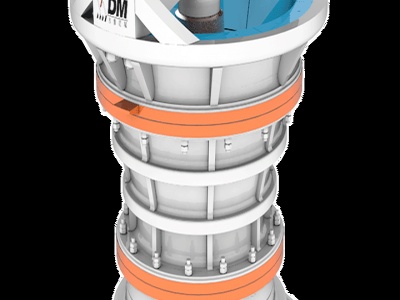

VRPM – AMCL Machinery Limited

Clinker grinding / Raw Material Grinding. We also offers combination of VRPM and Ball Mills along with single separator system to reduce no. of equipment in circuit which result in reduction of overall project cost. This circuit allows to get homogenized product from single dynamic which reduces logistic of .

Experience with grinding slag and clinker in a Loesche mill

Pfeiffer, VDZ tested clinker and slag ground to comparable size distribution with three different systems: a ball mill, vertical roller mill and high pressure grinding roll (HPGR).

Latest Posts

- تستخدم مخروط محطم طن في الساعة للبيع

- شركة التعدين الصناعية الهندية

- النفايات الصناعية محطم

- أسبست الكريسوتيل تجهيز المعدات

- الجير محطم الصانع

- طاحونة رخام رخيصة في الهند

- م الرمال محطم تكلفة المصنع

- الهند مصدر Chigayo المطاحن

- الدولوميت مطحنة تصميم قوات الدفاع الشعبي

- مورد رمال نهر جامو

- اتصالات مناجم الذهب والماس

- ريموند مطحنة تأثير للبيع

- ألاسكا الفك محطم أجزاء

- الحجر الجيري سحق المطرقة محطم

- Jharkhand عروض كسارة الحجر

- Vendeure De Machine De Fabriion De Clous Algerie

- Concrete Grinder In Brooklyn Ny

- Vsi Crusher Second Hand

- Plant And Barite Crusher

- Concrete Plants For Sale Uk

- Large Plastic Landscape Rock

- Types Amp Specifiion Of Belts In Industry

- Coal Crushers Material Specifiions

- Vibrating Feeder For Crushed Coal

- Impact Machine Stone Crusher

- Nigeria Sand Powder Making Equipment

- Atomatic Stone Crushing Plant In Argentina

- Mobile Crushing Equipmenttellurium Mining

- Vertical Shaft Impactor Sekunder Menghancurkan

- Double Roller Crusher Coal Machine Price Egypt