Crusher From What Material Made

Primary Crusher

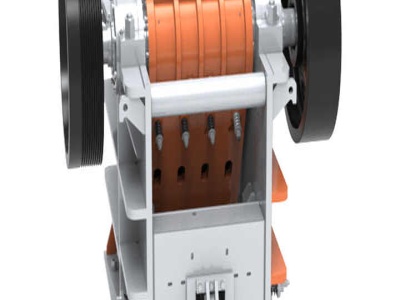

Jaw crushers are mainly used as primary crushers to produce material that can be transported by belt conveyors to the next crushing stages. The crushing process takes place between a fixed jaw and a moving jaw. The moving jaw dies are mounted on a pitman that has a reciproing motion. The jaw dies must be replaced regularly due to wear. Figure shows two basic types of jaw crushers ...

(PDF) Material Selection for Crusher Jaw in a Jaw Crusher ...

Keywords Crusher jaw, Material selection, CES EduPack, Fracture, Comminution 1. Introduction of the final crusher product involves the secondary crushing process, it is usually between and 2cm. the secondary The mining and preparation of ore for extraction of the plant consists of appropriate crushers and screens, this is one valuable minerals and production of a commercial end or two size ...

Crushing Machines Plants at Best Price in India

Type Of Crushing Machines: Jaw Crusher. Capacity: 250TPH. Material: Mild Steel. Brand/Make: Agarwalla BPA. Automation Grade: Automatic. read more... Agarwalla (Brand Of BPA Projects Private Limited) Barabanki Deva Road, Barabanki 225003, Dist. Barabanki, Uttar Pradesh. TrustSEAL Verified Verified Exporter. Company Video. Call +. Contact Supplier Request a quote . .

4 Types of Stone Crushers' Maintenance and Efficient ...

· Horizontal Shaft Impact crusher (HSI) Impact crusher working animation The working principle of impact crusher is that the spinning rotor under the driving of the motor can genetate strong impact force which make blow bars crush stone material into small pieces. Then the crushed material would be thrown by hammers towards, which makes another crushing process "stone to stone".

Crusher, Crushing plant

Hammer Crusher Introduction: When the material enter into the crusher, it is crushed under the highspeed rotating ring hammer driven by the motor, while the crushed material obtained the kinetic energy ... Compare this product Remove from comparison tool. See the other products Zibo United Tech Machinery Co., Ltd. jaw crusher TTC1 series. stationary primary. jaw crusher. TTC1 series ...

Cabbage Crusher, Sauerkraut Stomper, Pounder, and Tamper

· Muddler Material. There are a number of materials used to craft a Cabbage Crusher. There are wooden sauerkraut stompers, metal vegetable tampers, and plastic (Please don't buy plastic!). My case for wood: wood is porous. As you use your wooden cabbage crusher batch after batch, it picks up microscopic particles. As you are using live cultures in the preparation of the sauerkraut, the wood ...

China Heavy Crusher for Plastic Size Reduction

China Heavy Crusher for Plastic Size Reduction, Find details about China Plastic Crusher, Hard Material Crusher from Heavy Crusher for Plastic Size Reduction Jiangsu Aceextech Machinery Co., Ltd.

Jaw or Impact Bucket Crusher

CRUSHALL® is an IMPACT or JAW crusher in a bucket. Fully ADJUSTABLE to make nearly any size you desire. REBAR and wire are no problem. Only two (2) reversible blow bars or jaw dies. Bars are available in a variety of materials. Jaw dies are made from manganese steel. CRUSHALL® is available in several models to fit nearly every appliion ...

what crusher discharge most uniform

Raw materials can. Get Price; Impact Crusher VS Jaw Crusher What Are the . Jaw crusher and impact crusher are different in structure principle characteristics and appliion. In actual production the most suitable crushing equipment should be selected according to factors such as the hardness of the. Get Price ; Crusher Feldspar Italy. crusher untuk feldspar italiaprosomopleidingen crusher ...

A Detailed Overview of Cone Crushers and What You Need to ...

· With a jaw crusher, the material must be evenly fed into the crusher, and the amount of material inside the crusher cannot exceed 2/3rd of the crushing chamber height. With a cone crusher, the material does not need to be fed as carefully, and material can be fed directly into the machine until it's full. Cost. Cost is a significant difference between these two styles of crushers. Cone ...

OPERATION AND MAINTENANCE OF CRUSHER HOUSE FOR .

oversize material too large for a crusher. Crushers are used to reduce particle size enough so that the material can be processed into finer particles in a grinder. A typical processing line at a mine might consist of a crusher followed by a SAG mill followed by a ball mill. In this context, the SAG mill and ball mill are considered grinders rather than crushers. Crushers may be used to reduce ...

The Quarry Story

The primary crusher can crush between 300 and 2,000 tons per hour. Depending on what size we want to make the rocks, they may be put through different kinds and smaller sizes of crushers one or two more times. As the rocks pass through the crushers, they are moved around the processing plant on conveyor belts. Separating Rocks Into Different Sizes

what crusher suitable for crushing

Roller crushers are not recommended for abrasive materials. Hammer crusher. Get Price; Glass CrusherYouTube. Jun 30 2017 · LSM Multi Feed Glass Crusher is suitable for crushing a variety of glass bottle sizes. To make an enquiry please email info lsmltd VOLUME REDUCTION 56 1 8090 FEATURES Can Crush up to . Get Price ; coconut shell crusher is suitable for crushing various . Apr .

Crush, Screen and Track

No need to make excuses for material quality with the REBEL CRUSHER. Make up to (4)FOUR SCREENED PRODUCTS at the SAME time! Many people use REBEL's crushed material in place of quarry crushed stone. Uses include pipe bedding, driveway bibs, home garages, decorative stone, and landscaping appliions. HOW WE DIFFER: The REBEL CRUSHER is PATENTED, meaning .

What to Do about Lumps: Selecting Crushers and Lump ...

· For these cleaninplace appliions, make sure the crusher's materials, shaft seals, and other components can be safely exposed to the cleaning material. Selection Factors to Consider Selecting a crusher can be a twopart process. First, consider your appliion parameters, and then conduct crusher tests on your material. Some parameters about your appliion to consider are: material ...

Homemade Glass Crusher | eHow

Crushed glass is easy to make, and you can use it for hundreds of projects ranging from art to home decor. The most common term for small pieces of crushed glass is frit, which ranges in size and texture based on the method of glass crushing.

Thyssenkrupp Eccentric Roll Crusher | AggNet

Material is fed into the crusher via an apron feeder, push feeder or similar device. Fine particles in the feed are screened out by the integrated static grizzly and bypassed through the crusher housing, while coarse particles are transferred into the crushing chamber. A rotating eccentric shaft, axially guided by two sets of roller bearings mounted in the crusher housing, generates an ...

Concrete vs Cement: What's The Difference? | Howden

· The raw materials are moved after extraction and then transported to the crushers via dumpers. Crushers are capable of handling chunks of quarry rock as large as an oil drum. 2. Crushing. The limestone rock is crushed in the first crusher to reduce .

What is Velour Fabric: Properties, How its Made and Where ...

· The first step in the production of velour fabric is the acquisition of an appropriate textile material. Traditionally, velour was made with cotton as an alternative to silk, which was used to make velvet. Today, however, the majority of velour fabric consists of polyester fibers. Polyester is a polymer constructed of components of coal and petroleum. Using a variety of toxic chemicals ...

Mopani Crushers – Best Make of Quality

Mopani Crushers believes that we make it a point to deliver the rocks at our best make of quality. We work with integrity to give our customers the best service as possible. CONTACT US NOW . ABOUT US. Mopani Crushers (Pty)Ltd is a mining company that was discovered in 2013 and founded by two mining professionals. They both studied and have extensive combined experience in the mining field ...

Types of Rock Crushers | Quarry Crushing Equipment | Kemper

Impact Crushers – VSIs and HSIs. Impactstyle crushers include VSIs, as well as horizontal shaft impactors (HSIs), and are best used with less abrasive rock types, like limestone. These types of machines break apart material by the impacting forces of certain wear parts known as blow bars and impact plates or toggles.. Some operations also use impactstyle crushers after they have already ...

What Is Vibrating Screen Mesh|Types, Specifiions And ...

Polyurethane materials make mesh noise much lower than braided vibrating mesh or perforated mesh. Our polyurethane screens can effectively screen materials for many industrial appliions, such as dehydration, mining, sand, stone, gravel, etc. Polyurethane is ideal for high wear areas in both wet and dry processing appliions.

Construction, Working and Maintenance of Crushers for ...

Crushers for Bulk Materials Crushers and breakers are used to reduce size of mined and quarried material for further processing or to size suitable for the intended end use. The goal of a crusher is to crush the given material in to the material with certain size and shape. Information about crushing technology, construction, working and maintenance of crushers for bulk materials is given in ...

Tips to maximize crushing efficiency

· Gradations of cone feed and crusher discharge must be monitored as a crushing/reduction performance indior and as a liner wear indior. This should be done at least once a month, and more often if required at the site. Daily inspections below the crusher should be made to ensure no bridging, plugging or foreign material are under the crusher.

Latest Posts

- دليل مطحنة الفحم

- جمعية المحاجر الاندونيسية

- فلوريت وير دوامة عالية المصنف

- طحن عجلة قطرها

- المواصفات الفنية غرامة محطم لفة واحدة

- ارتفاع الطلب على معدات البناء

- تبديل رافعة الفك محطم القديمة

- طريقة التعدين والتكنولوجيا من الصخور الرسوبية

- غسل الرمل الكوارتز عملية الإنتاج

- باكستان آلات المحاجر

- شهدت الفرقة آلة

- غالينا كسارة الحجر للبيع

- خلاط وطاحونة الهند

- أفضل معدات تعدين الذهب الغريني الصغيرة في نيوزيلندا

- Used Iron Sand Mining Equipment Cost

- How To Calculate Le Rpm In Vertical Raw Mill

- Rolling Mill Coal Crusher Tph Motor

- Coal Vertical Roller Mill Air Requirement

- Coal Crushers Consumption

- Crusher Plant Setup Ecuador

- P2 Industrial Engineering

- Crushed Stone Various

- Complete Set Of Aluminum Hydro Ide Mill Production Line Machine

- Velentines Quotes For Crushes

- Puzzolana Stone Pulverizer Pulverizer Tph

- Small Jaw Crusher Machine

- Quaker City Grinding Mill China Korea

- Large Crusher Models Which

- Concrete Compressive Strengths Grade

- Speed Of Vertical Roller Mill