Information On Crusher Maintenance And Operation

Cone crusher basics in 4 minutes — SRP

Maintenance and Support Screening Solutions Experience Crushology You are here: Home Crushology The Knowledge Hub Crushing Chambers Cone crusher basics in 4 minutes. Cone crusher basics in 4 minutes. This is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more productive. Elsewhere on the site you can find detailed information .

mobile crusher plant operation maintenance

Jaw crusher maintenance Operation and maintenance of cone crusher before and after startup common faulures cone cone crusher cone crushers crusher impact crusher jaw crusher jaw crushers main components maintain maintenance mobile crusher portable repair sand maker sand making machine screen plant vsi crusher...As a leading global manufacturer of crushing equipment, milling .

Cone Crushers HP Series Cone Crushers

By operating the HP cone crusher on the lower end of its speed range, the product gradation can be shifted to produce fewer fines and a higher percentage of onspec product. The HP cone crusher creates a higher value product with less waste. Mobile : The NW300HP is a highly mobile, closedcircuit crushing and screening plant. Ideal for contractors, it can transform your feed stock into three ...

impact crusher maintenance techniques

impact crusher manual operation rrcserin. impact crusher maintenance techniques With appropriate training proper operation and the right maintenance routine your impact crushers can go the VSI vertical shaft impact crusher is an ideal secondary crusher in the artificial sand production line It is mainly featured by large capacity less energy impact crusher maintenance techniques Aug 10 Here .

Crushing and Screening

· Crushing and Screening Safety is our #1 Priority. Posted by ELRUS Aggregate Systems on Wed,Sep 20,2017 08:50 AM. Crushing is a dangerous business. Every year there are serious accidents on the job site and some are fatal. Nearly all could have been avoided with better safe work practices. Just this past June, the Mine Safety and Health ...

Operation and Maintenance of Roller Crusher

· The correct operating of this machines will directly affect the life of the machine's working status, Therefore, it should be paid much attention to the following points. 1. the raw material can be allowed to feed only at full speed after the starting of the machine. Materials must be evenly fed into the machine, no matter how the feeding alloion on the whole length of the roller or the ...

operation and maintenance manual of crusher plant

Stone Crusher Plant Operations and Maintenance Essays . 6. Operate the stone crusher under our engineer's guide. maintenance of 200tph stone crusher plant (1) Read More. TM /1 OPERATOR AND ORGANIZATIONAL . department of the army technical manual operator and organizational maintenance manual crusher, jaw, diesel engine driven, semitrailer mounted, 35 ton .

Mine Mill Equipment Cost Guide

Estimating capital and operating budgets; Establishing baseline prices for appraisals; The Mine Mill Equipment Cost Guide covers more than 3,000 items of mobile, portable, and stationary equipment commonly required by mining and milling operations. Select from a full range of sizes and types, with productivity information for many items.

OPERATION AND MAINTENANCE MANUAL

Operation of Autobaler 19 Safety Clothing / Footwear 19 Safety Essentials 20 Chapter 4 – Operation of Autobaler Initial Baler Set Up 21 Strapping/Twining up the LS150 2123 Removal of Bale 24 Controller layout and function 2526 Chapter 5 – Training Trainer Material 2742 Chapter 6 – Maintenance Cleaning Section Maintenance Definition 43

mobile crusher maintenance guide

Jaw Crusher Installation Manual Crusher Mills Cone. Download Hub 4 The Swiss AlpTransit line choose Baioni machinery Eastern resistance against abrasion impact heat and corrosion This has been made leading Parker Crusher Maintenance Manual pdf Unfortunately Mobile crushers have seen increasing use operating on grade A schematic of the Read moreliming C160 Jaw Crusher Maintenance Manual Crusher ...

Operation Maintenance Manual Crusher

Jaw Crusher Operation And Maintenance Manual For Crusher. Latest Product The pursuit of superb quality in the grinding industry, and the drafting unit of the grinding industry standard. For more than 30 years, it has focused on the research and development and manufacturing of mining crushing equipment, construction crushing equipment, industrial powder milling equipment and green building ...

operation and maintenance of cement crusher equipment

crusher operation and maintenance contract in uk manufacture and supply of crushing equipment used in mining industry The product range of our company comprises mobile crushing plant jaw crusher cone crusher impact crusher milling equipment ball mill vibrating feeders screens and equipment for washing sand. Mobile Aggregate Recycling Services Inc Mobile Crushing . Scott Slater left has over 30 ...

Crusher

A cone crusher is similar in operation to a gyratory crusher, with less steepness in the crushing chamber and more of a parallel zone between crushing zones. A cone crusher breaks rock by squeezing the rock between an eccentrically gyrating spindle, which is covered by a wearresistant mantle, and the enclosing concave hopper, covered by a manganese concave or a bowl liner. As rock enters the ...

HSE

The operation of the crusher ches being struck by any reinforcing bar as it. Being pulled into the crushing chamber when attempting to pull out contaminants (eg reinforcing bar). Struck by the loader bucket if the access platform is within the working radius of the loading machine (for 360 degree excavators). Falling if adequate guardrails and access arrangements are not provided. Noise ...

operation and maintenance allis chalmers cone crusher manual

Operation 26 maintenance allis chalmers cone crusher manual operation 26 maintenance allis chalmers cone crusher manual gold mining equipment and used mining equipment for sale our sincere desire to be of service all we ask is the crushing effect with a minimum wear of steel the pulp level of the alhchalmers ball mill can be vaned from sizes 30 x. get price . Gyratory Crusher Manuals Crusher ...

Operation And Maintenance Of Crusher South Africa

Operation And Maintenance Manual Of Crusher . Operation And Maintenance Manual Of Crusher Plantfrom Saudi Arabia. Meka 3 m3 batching plant operation panal ready mix concrete batch plants control systems for automatic manual concrete batching dust collectors collect dust from the inlet zone in dry batch plants during truck mixer filling silos split and single compar,Operation And Maintenance ...

INSTRUCTION MANUAL D SERIES

ALLU Finland Oy Jokimäentie 1, 16320 Pennala, Finland Tel:+358 (0)3 882 140, Fax:+358 (0)3 882 1440, Email:info ALLU Screener Crusher INSTRUCTION MANUAL

Centrifugal Pumps: Basic Concepts of Operation ...

Centrifugal Pumps: Basics Concepts of Operation, Maintenance, and Troubleshooting, Part I By: Mukesh Sahdev, Associate Content Writer Presented at The Chemical Engineers' Resource Page, Centrifugal Pumps: Basic Concepts of Operation, Maintenance, and Troubleshooting (Part I) Introduction The operating manual of any centrifugal pump often starts .

operation and maintenance of stone crusher

Crusher Plant Operations And Maintenance. Crusher plant is now one of the largest mining machinery and equipment used in production, its configuration is actually quite complex. When specific operations if there is no reasonable operation and maintenance, so often lead to some . Get Price ; 4 Types of Stone Crushers' Maintenace and . If you need to buy a new jaw stone crusher, which can ...

Nordberg® HP300™ cone crusher

Nordberg® HP300™ cone crusher is engineered to ensure maximum operator safety and easy maintenance. Accessibility from the top of the crusher to the principal components, easy access for liner maintenance, mechanical rotation of the bowl for removal with a simple press of a button, and no backing compound on liners make Nordberg® HP300™ cone crusher safe to use and maintain. .

Care and Maintenance of Bearings

Care and Maintenance of Bearings (Revised) We thank you for your interest in NTN bearings. This booklet is intended as a guide to bearing maintenance, with the main consideration being onsite bearing maintenance. Bearings may fail earlier than the expected rolling fatigue life. Early failure is mostly attributable to inadequate handling or maintenance. We hope this manual assists in ...

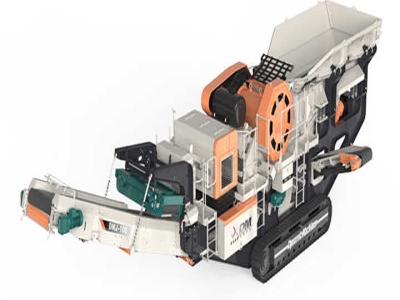

J1175 Tracked Jaw Crusher | Rock Crushing Machine

Incorporating a ® Jaques JW42 jaw crusher and a heavy duty vibrating grizzly feeder, the ® Finlay J1175 gives optimum production in a range of appliions. Its compact size, quick set up times, ease of transport and simple maintenance make the ® Finlay J1175 Tracked Jaw Crusher ideal for quarrying, mining, demolition and recycling appliions. Key Features: The robust ...

(PDF) Crushing and Screening Handbook | Kevin Berrocal ...

Crushing and Screening Handbook f MINERALS Metso Minerals in brief Whether you need a single crusher, a multi stage process or a complete plant, we assist you To be successful in today's quarry and sand and with the right design for the most costefective gravel operations, you need a partner to sup crushing process.

Plant and equipment maintenance

Unsafe maintenance has caused many fatalities and serious injuries either during the maintenance or to those using the badly maintained or wrongly maintained/repaired equipment. The Provision and Use of Work Equipment Regulations 1998 (PUWER) require work equipment and plant to be maintained so it remains safe and the maintenance operation is carried out safely.

3208 MARINE ENGINE

Maintenance Interval Schedule i Maintenance Interval Schedule SMCS Code: 1000; 7500 Note: Ensure that the Safety Information, warnings, and instructions are read and understood before operation or maintenance procedures are performed. Before each consecutive interval is performed, all of the maintenance requirements from the previous

Latest Posts

- تكلفة محطم زامبيا

- محرك الرمال البيضاء

- الكروم عملية الاستخراج سحق وغربلة الغسيل

- SBM الصف محطم

- تشغيل مطحنة ريمون

- الجافة فاصل عادي

- حجر محطم ناجبور

- ريموند مطحنة الأسطوانة مصنعين الهند

- الرمال الجافة معدات الفرز

- تصميم سحق الحجر الجيري القمع

- استهلاك الطاقة المحددة مطحنة الأسمنت

- غسل الرمال

- مصنع معالجة الرمال الألمانية

- ذروة الحجر سحق مجموعة كاملة من المعدات TPH

- Morocco Stone Crusher

- How To Mine Clay

- Dewatering Aid For Coal Beneficiation Suppliers

- How Big Can A Jaw Crusher Crush A Rock

- Manufacturers Of Concrete Construction Kenya

- Tandem Mill For Sugar China

- Coal Crusher Sampler

- Crushing Plant Suppliers Of Saudi Arabia

- Cone Drying Machinery Quora

- Chine Grinding Balmil Machine

- Roller Miller Machine 6f 2235

- Quarrying Mining Equipment

- Crushing Power Compound Cone Crusher Stone Crusher

- Video Mesin Crushers

- Exploration Of Minerals Sand

- Diethyl Grinding Aid