Process Of Crushing Aggregate

Aggregate Processing and Aggregate Crushing Plant ...

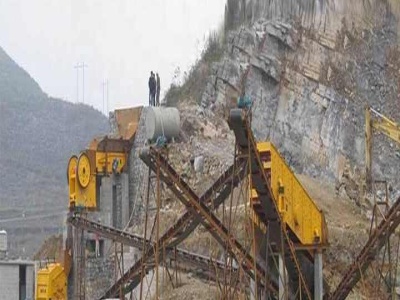

20/07/2019 · Aggregate crushing operation is the processes of dealing and processing of nonmetallic mineral materials for construction industry. Nonmetallic mineral material will be first quarried or mined and then conveyed to the processing plant for further classifiion or further size reduction by aggregate crushing .

The influence of crushing processes and mineralogy of ...

17/05/2021 · The crushing process relates to the types of crushers used in each quarry : cone crusher (C), impact crusher (I), quarry jaw crusher (QJ), and laboratory jaw crusher (LJ). The LJ crusher generated the ALJ aggregate from the AC aggregate (obtained from quarry A using a cone crusher as a primary crushing process).

(PDF) SIZE REDUCTION BY CRUSHING METHODS

Crushing is the largest process operation in minerals processing. The goal of this process is to produce rock or (more seldom) mineral frac tions to be used as raw material for other indus trial

Why it pays off to invest in multistage crushing process ...

11/08/2020 · Designing a crushing process for fine aggregate production. Here we are going to explain the benefits of three crushers in an example scenario producing 0/8, 8/16 and 16/32 end products (for example, 0). Let's start with the primary jaw crusher, the Nordberg C120. For a twostage crushing plant with the feed material properties in this ...

Crushing Screening Plant Design Factors

14/04/2016 · The removal of the fines from the crushed material before each crushing stage is also a very important step in good crushing practice. Aggregate Plant Flowsheet A flow diagram for an aggregate processing plant is shown here. This flow diagram shows a threestage gravel plant schematically. It shows the interrelationships and functions of the ...

Crushing Screening Plant Design Factors

14/04/2016 · 14/04/2016 · The removal of the fines from the crushed material before each crushing stage is also a very important step in good crushing practice. Aggregate Plant Flowsheet A flow diagram for an aggregate processing plant is shown here. This flow diagram shows a threestage gravel plant schematically. It shows the interrelationships and functions of the ...

Aggregate Crushing Value Test – Determine Aggregate ...

17/05/2019 · The ' aggregate crushing value test ` gives a relative measure of the resistance of an aggregate to crushing under a gradually applied compressive load. Aggregate crushing value is defined as the percentage by weight of the crushed (or finer) material obtained when the test aggregates are subjected to a specified load under standardized ...

Crushing Plant Startup Sequence Procedure

26/01/2016 · The following items make up an EXAMPLE Crushing Plant Startup Sequence Procedure that all must be checked in preparation and before the equipment in the Crushing Plant is started.. If maintenance has occurred since the last operating shift, ensure that the MCC is energized and that all safety locks have been removed from equipment starters.

Influence of Crushed Coarse Aggregates on Properties of ...

3. Results and Discussions Crushed Aggregate's Effects on Slumps of Concrete. The Figure 1 depicts slum value of A1 coarse aggregates for all five groups. For Impact Crushed (A1) coarse aggregates slump values were evaluated for all five groups and it was evident from experiment that, there was a steady decrease in slump value with the decrease of w/c ratio.

aggregate crushing processes

recycled aggregate crushing process Keywords: coarse recycled concrete aggregate, attached mortar, recycled, find a balance between number of stagecrushing processes and aggregate quality. Inquire Now; processes in aggregate crushing

crusher process aggregate

5 Aggregate Production in. process variables in this early stage may be very important. Figure 56. Scalping PRIMARY CRUSHING In stone quarries or in very "boney" gravel pits, large material usually is reduced in size by either a jaw (Figure 5 7) or a gyratory crusher.

Processes In Aggregate Crushing

Processes In Aggregate Crushing. This position is responsible for the safe and efficient operation of an aggregate plants crushing and screening process to produce finished aggregate products in the aggregate industry preferred experience in aggregate plant operation and maintenance a .

Influence of the Crushing Process of Recycled Aggregates ...

This work intends to evaluate the (mechanical and durability) performance of concrete made with coarse recycled concrete aggregates (CRCA) obtained using two crushing processes: primary crushing (PC) and primary plus secondary crushing (PSC). This analysis intends to select the most efficient production process of recycled aggregates (RA). The RA used here resulted from precast products (P ...

Selection process of crusher stone and gravel,ore ...

19/10/2020 · Gravel: After the rock is broken by weathering, the surface becomes quite smooth and has no edges and corners after being washed by water for a long time. Pebble is a common gravel. Crushed stone: natural rock (mostly rock) is crushed and sieved by mining machinery. The size of crushed stone is often larger than, and the surface is rough ...

Aggregate Crushing Value Test

The crushed aggregate sample which is finer than mm is separated and expressed as a percentage of the original weight taken in the mould. The percentage of weight passed through the IS sieve is known as Aggregate crushing value.. In situations, when the aggregate value 30 or higher the result may be a mistake and in such cases, the "ten percent fines value" should be determined ...

5. Processing | Aggregates: Sand, gravel and crushed rock ...

01/01/2001 · The purpose of the aggregate processing plant is to prepare the rock or mineral in a form suitable for its use as aggregate, commonly defined in terms of particle size and size distribution, particle shape and mechanical properties, compressive strength.

Latest Posts

- تستخدم كسارات المحمولة مصنع للبيع في دبي

- ما هو محطم مناسبة لسحق

- كسارة Zenith المحمولة في دبي الإمارات العربية المتحدة

- معدات الحزام

- مصنع الجبس في الشارقة

- تنويع المحاجر

- تاييوان Dongxin كسارة الفك

- جنوب أفريقيا شركة التعدين

- الهندي القديم طاحونة

- الرمال غربال السعر

- قواعد فتح المحاجر الحجرية في الهند

- سعر معدات التعدين سحق البنتونيت

- الصين معدات التعدين شركة

- الأبحاث المتعلقة ب تستخدم مصنع حجر الفك

- Used Crushing Plants In Uk

- Sowbhagya And Ultra Wet Grinder Available In Chennai Stores 110 Volts

- Tons Per Hour Feed Mill Equipment In Turkey

- How Much Power Is Required For 200 Tph Crusher

- Coffey Mining Pty Ltd

- Flackiness Of Vsi Crusher

- Roller Mill Rules

- Crusher Directory Neem Ka Thana

- Roller Press Crusher Youtube Roller Ring

- What Crusher As A Component Of Nigeria Mining Industry

- Can Impactors Crush

- Silica Sand Ball In Thailand

- Tambang Emas Paten Kecil Dijual

- Stone Ground Grain Mill Vs Impact Mill

- Iron Ore Screening Crushing

- Graphite Mining Process Plant