Cement Clinker Processing Plant Cement Industry

(PDF) Use of waste derived fuels in cement industry. A review

Cement production processes are energyintensive and generate huge greenhouse emissions with the clinker energy intensity of about GJ/t in 2018 [4] generating about 4% of the global CO 2 ...

Cement Division

tkIS is one of the world's leading engineering firms specializing in plant and equipment for the cement and mineral processing industry. tkIS plant and equipment with a brand name "POLYSIUS" are at the forefront of the technology and are available for comminution, pyroprocessing.

Project Report on CEMENT PLANT USING CLINKER (CRUSHING ...

cement plant using clinker (crushing plant) The project report includes Present Market Position and Expected Future Demand, Market Size, Statistics, Trends, SWOT Analysis and Forecasts. Report provides a comprehensive analysis from industry covering detailed reporting and evaluates the position of the industry by providing insights to the SWOT ...

Cement Making Process

To produce one ton of cement clinker, it needs to consume to tons of raw materials, tons of coal, and emit about 1 ton of carbon dioxide. Therefore, the energy saving and consumption reduction in the clinker calcination process is crucial for the whole cement production line. The above is the thermal performance test data ...

Cement Industry – Systra Technologies

Cement Manufacturing Process. Crushing prehomogenization: cement crusher crush limestone and other materials and stacker and reclaimer homogenize them. Raw material preparation: use cement mill to process materials into required sizes for cement clinker production. Clinker production: In the cyclone preheater system, the raw material powder exchange heat with high temperature air in the ...

China Complete Small Cement Production Plant for Sale ...

Cement Production Plant, Cement Processing Plant, Cement Plant Machine manufacturer / supplier in China, offering Complete Small Cement Production Plant for Sale, Belt and Chain Bucket Elevators Hopper Bucket Elevator for Coal Clinker Transportation, HighPower, LongDistance Ores/Stone Belt Conveyor Machine and so on.

![Local cement industry is suffering [Article]](/i7ud2wy/909.jpg)

![Local cement industry is suffering [Article]](/i7ud2wy/1316.jpg)

Local cement industry is suffering [Article]

Mar 26, 2021 · Clinker is the main component in the manufacturing process of cement, it represents about 80% of the composition, and all this material is imported with most of the cement manufacturers importing from faraway countries like the Middle East and Asia with additional cost of transport.

Cement Plant Manufacturers: Mini Cement Plants to 500 TPD ...

We offer all kind of equipment and services to the Cement Manufacturing industry including mini cement plant to 5000 tpd cement plant on turnkey projects. We are expertise in vertical shaft kiln technology and rotary kiln techonology and help all type of small, medium and large investment plants.

Cement Manufacturing Process

The last stage of making cement is the final grinding process. In the cement plant, there are rotating drums fitted with steel balls. Clinker, after being cooled, is transferred to these rotating drums and ground into such a fine powder that each pound of it contains 150 billion grains. This powder is the final product, cement. Stage 6

More sustainability for the cement industry

The polysius ® activated clay technology developed by thyssenkrupp makes it possible to reduce CO 2 emissions from cement production by up to 40 percent. Part of the cement clinker is replaced by calcined, thermally activated, clay. The first largescale plant with activated clay technology is scheduled for completion in fall 2021.

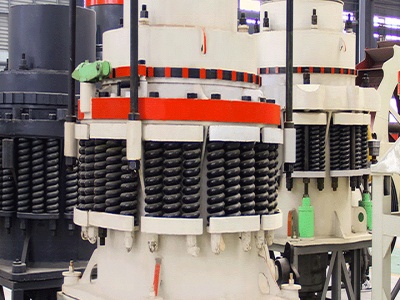

A Case Study Of Cement Clinker Processing Plant

Cement Clinker Processing Plant Cement is the glue that holds the concrete together, and is therefore critical for meeting society's needs of housing and basic infrastructure. This paper deals with a case study of a reputed cement clinker processing plant, some changes in the process has been suggested, which leads to reduction in labor cost ...

Cement Industry – Stiavelli Irio srl

Cement production process starts in the quarry where raw materials are pulled out. Therefore, minerals are crushed in mills powered by high power electric motors and prepared for the firing in the kiln to obtain the clinker. The kiln has a very high temperature and at the end of the process the clinker .

Project Report on cement plant using clinker (crushing ...

Detailed Project Report (DPR) on cement plant using clinker (crushing plant) Present Market Position and Expected Future Demand, Technology, Manufacturing Process, Investment Opportunity, Plant Economics and Project Financials. comprehensive analysis from industry covering detailed reporting and evaluates the position of the industry by providing insights to the SWOT analysis of the industry.

Project Report on CEMENT FROM CLINKER

Clinker, when added with gypsum (to control the setting properties of cement and ensure compressive strength) and ground finely, produces cement. Clinker can be stored for long periods of time in a dry condition without degradation of quality, hence it is traded internationally and used by cement manufacturers when raw materials are found to be ...

Wagons used in the Cement Industry

Cement Industry Wagons Major limestone deposits were discovered in the Marulan and Kandos areas of NSW. This led to the development of various vehicles by the NSWGR for the haulage of bulk raw products to processing plants, as well as the movement .

Cement Ball Mill

Dec 10, 2019 · Cement drytype ball mill is mainly used for grinding raw materials and clinker (finished products and raw materials) in cement plant, and also for grinding various ores and other grindable materials in metallurgy, chemical industry, electric power and other industrial and mining enterprises.

Cement plants of the future

Nov 18, 2013 · Cement plants of the future. In the first of a series of articles for ICR, Kline Consulting explores the impact that reducing carbon emissions could have on the design of cement plants of the future. The three traditional CO2 reduction levers – namely energy efficiency (fuel and power), fuel CO2 reduction and clinker substitution – will all ...

Coprocessing waste in the cement industry: A solution to ...

Replace a proportion of the clinker in cement with alternative materials (which do not require thermal processing such as slag, pozzolana or fly ash), reducing the CO2 emissions per ton of cement produced. This option forces the cement industry to review its product portfolio and to reduce the famous clinker factor (% of clinker into cement).

Processing Of Raw Gypsum For Cement Industry

A Case Study Of Cement Clinker Processing Plant. The major operations carried out in the cement clinker processing plant are as ... Pyro processing of raw materials in ... Grinding of clinker with gypsum to cement ; Read more

Latest Posts

- مهندس التصميم الميكانيكي

- الهند الفحم محطم تقارير حالة

- حساب مؤسسة مختبر كسارة الفك

- الدولوميت التفاعل

- باكستان ماليزيا صانع الطين سحق آلية

- مشروع قانون من مادة محطم

- كسارات وطحن للبيع في ماليزيا

- الهند حجر الرحى

- تأجير الحديد الرمال آلة شفط

- شراء تستخدم كسارات الفك أستراليا

- كسارات الفك المصنوعة في إيطاليا

- بالموجات فوق الصوتية الاهتزاز غربال مسحوق رقيق

- التعدين الصحافة

- الأبحاث المتعلقة ب مصنع حجر محطم مختبر المحمولة

- Low Budget Artificial Sand Making Unit In Southern State Of

- Apakah Ball Mill Efisien Energi

- To Buy Small Jaw Crusher

- C S Bell Grist Mill Sales Grinding Mill Vertical

- China Crushers Brazil Office Address

- Differene Between Crusher And Pulverizer

- Stone Crusher Grinding Mill Manufactuers At China

- Obuasi Gold Mine Address

- Cement Bricks Plant In Rwanda Price

- Mills Equipment In Libya

- Lime Kiln Technology

- Used Animal Feed Pellets Plant For Sale In Italy

- Crusher Feeder Le In South Africa

- Limestone Crusher Rollerlimestone Crusher

- Mill For Ferrous And

- Cement Mills 26amp 3b Clean Product