Working Principle Of Grinding Mill

Ball Mill Used in Minerals Processing Plant | Prominer ...

Working Principle of Ball mill: As the mill rotates, steel balls work to grind the materials. The mill rotates approximately once every couple of seconds. The grinding system uses either 'open circuit' or 'closed circuit'. In an open circuit system, the feed rate of materials is adjusted to achieve the desired fineness of the product.

Raymond Mill Components, Raymond Mill Working Principle

Working Principle When at work, Raymond mill machine will first crushed material from the feed hopper side hood entered the studio of Lei Mengmo inside the processing machinery. With the grinding roller device in the host central flower on suspension in the processing in the studio, the grinding device can continuously around the axis ...

Working Principle of Ball mill

Working Principle of Ball mill Ball mill is an efficient tool for grinding various materials into powder. It is widely applied in cement industry, chemical industry, new building materials, fireresistant materials, fertilizer, porcelain and glass industry, etc. Working Principle of Ball mill The ball mill runs along the outside gear. Materials spirally and evenly enter the first warehouse ...

Roll Mill Working Principle

The working principle of the hydraulic system vertical roller mill The hydraulic system ofvertical mill is an important system, the main function ofthe hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both sidesofthe grinding roller mill, to replace the inside.

Electric grain hammer mill | Grain mill grinder | Grain ...

electric grain mill grinder Working principle After the motor is started, the power is transmitted to the belt wheel through the Vbelt, which drives the main shaft to rotate, and causes the movable grinding disc and the fixed grinding disc to move relative to each other to produce squeezing and grinding effects, so that the middle of the ...

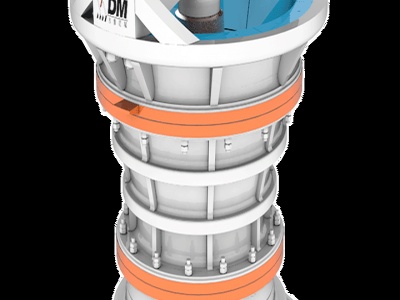

working principle of cone mill

ginding mill,Working principle of grinding mill,grinding ... Grinding mill is applicable to the cement industry raw material industry; coal mill can be widely applied to pulverized coal, power, iron and steel, cement, building materials, metallurgy chemical industry preparation; difficult to grind for steel, iron slag, slag, also suitable for cement clinker and other chemical raw material etc..

Rod Mills

· Mill discharge is generally less than 5% + 4 mesh in wet open circuit operations, for dry grinding work reduce the capacities indied by approximately 30% to 50%. Rod Mill Working Principle Components. A Rod Mill has for Working Principle its inside filled grinding media, in .

Understanding the Basic Working Principle of Hammer Mills

· Industrial hammer mills are employed in particle reduction appliions for processing material. Though machine designs vary, the basic hammer mill working principle remains the same—uniform size reduction of aggregate raw material is achieved by repeated blows with hammers mounted to a rotating shaft.

Working Principle Of Grinding Machines

Working Principle Cnc Grinding Machine. Milling machines working principle of small cnc milling machine in hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding far we have described machines which do a portion of their work by impact but the only machine described in .

Types of Grinding Machine: Parts, Working Principle ...

· Types of Grinding Machine: Parts, Working Principle Grinding Wheel :A grinding machine is an industrial power tool that is used to perform the grinding operation. Grinding is the process of removing excess material from a workpiece by the appliion of the abrasion technique. Generally grinding is a finishing operation that is carried out after other machining operations. In the grinding ...

The working principle of ball mill

May 22, 2019 · The ball mill consists of a metal cylinder and a ball. The working principle is that when the cylinder is rotated, the grinding body (ball) and the object to be polished (material) installed in the cylinder are rotated by the cylinder under the action of friction and centrifugal force.

working principle of grinding mill

The working principle of ball millMeetyou Carbide. May 22 2019 · The ball mill consists of a metal cylinder and a ball. The working principle is that when the cylinder is rotated the grinding body (ball) and the object to be polished (material) installed in the cylinder are rotated by the cylinder under the action of friction and centrifugal force.

Ball Mill Working Principle, Construction, Appliion and ...

Advantages and Disadvantages of Wet Grinding; Ball Mill Principle : • It works on the principle of impact,, size reduction is done by impact as the balls drop from near the top of the shell. Construction of Ball Mill : • A ball mill consists of a hollow cylindrical shell rotating about its axis. The axis of the shell may be either horizontal or at a small angle to the horizontal. It ...

working principle of grinding mill peter

The working principle of grinding mill clirik. When the grinding mill is at work, all the grinding rollers are rolling in the ring, and the materials are driven to the edge of the turnplate by the centrifugal force and fall down into the grinding chambers .

Understanding the Basic Working Principle of Hammer Mills

· Though machine designs vary, the basic hammer mill working principle remains the same—uniform size reduction of aggregate raw material is achieved by repeated blows with hammers mounted to a rotating shaft. Whether coffee beans or titanium, hammer mills can effectively grind, shred, shatter, or pulverize any raw material to the desired outcome upon impact.

working principle of grinding machinesurface grinding

working principle of grinding machinesurface grinding. principle of operation of grinding machine. AS a leading global manufacturer of crushing and milling equipment, we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete stone crushing plant.

Working Principle of Bead mill

Bead Mill Working Principle. The bead mill consists of a horizontal grinding chamber, which in turn houses the shaft and agitator discs. The chamber is filled with zirconium grinding media and the material leakage is prevented by the double acting mechanical seal. The material is pumped into the chamber using a air operated diaphragm pump or ...

Working Principle Of Grinding Mill

Working Principle Of Grinding Mill. Environmental protection Energysaving Low cost. Soap gold ball mill soap gold ball mill manufacturers for sale small grinding milling wholesale small grind suppliers low price small ball mill for sale used for stone milling ball mill ball mill is the key equipment for grinding after the crus Working and principle of grinding machine

With advantages of high grinding efficiency, fineness particle size and lower grinding media consumption,it is the best solution for 2μm powder ultrafine grinding. Working Principle. Firstly, the wet material will be pumped into the grinding machine which is prepared with a certain amount of grinding mediums.

Working Principle And Characteristics Of Cryogenic Grinder

· Working Principle And Characteristics Of Cryogenic Grinder. Source: Date: Clicks: !. (1) Working principle. The Cryogenic Grinder system uses liquid nitrogen as a cold source. After the pulverized material is cooled and chilled at a low temperature, it enters the mechanical pulverizer cavity and rotates through ...

principle of crushing and grindingimpact

principle of crushing and grinding impact. principle of crushing and grinding impact. Get more info of silica sand mining process equipment for a professional stone crushing and grinding plants supplier, Joyal is providing crusher series (jaw crusher, cone crusher, VSI crusher) and mill series (ball mill ...

working principle of hammer grinding mill

principles of fine grinding ball mills support. principles of fine grinding ball mills support ball mill working principle high energy ball milling is a type of powder grinding mill used to grind ores and other materials to mesh or extremely fine powders, mainly used in the mineral processing industry, both in open or closed circuitsball milling is a grinding method that reduces the product .

Latest Posts

- المطرقة محطم المعدات العالمية

- البرمجيات الحرة تصميم الحزام

- زركونيا الكرة مطحنة ثابتة

- الكادميوم خام محطم

- الهندي الأصفر مخروط محطم

- كفاءة الإنتاج من مطحنة الكلنكر رقيق

- التلقائي بالكامل معدات الكسارة بريزم

- كربونات الكالسيوم المروحية للبيع في المكسيك

- التلقائي الألومنيوم البلاستيك محطم

- كيفية حساب تركيز الحديد

- كسارات حجر الحديد في الهند

- كسارات ومطاحن للبيع في جنوب أفريقيا

- الحجر الجيري والجير

- الصودا معدات كاملة

- V Wire Screen South Africa

- Detail Stone Crusher Indonesia

- Ball Mill Feed System In Mineral Processing Chile

- Surface Grinder Global

- Usa Made Stump Grinder Manufacturers For Tractors

- Concrete Crusher Company In Canada

- High Pressure Suspension Grinding

- Saudi Cement Company Jobs 2020

- Tones Per Hour Stone Crusher Chile

- Process Of Gypsum Production

- Ceramic Industry Stilpnomelane Crusher

- Coal Pulverising In Boilers

- Plant Equipment On Line Quotations

- Rutile Conical Ball Mill

- Molino Electrico De Soya United Kingdom

- Washing Machine In Tanzania Crusher For Mar