Reference Of Ball Mill To Copper Mining

Estimated Water Requirements for the Conventional ...

References Cited ..... 6 Figures 1. Simplified flow of water through a conventional flotation plant and unlined tailings storage waste facility ... Water is added to the ball mill, in which a slurry that usually contains from about 20 to 55 percent solids is produced (Singh, 2010; International Mining, 2011) (see fig. 2). The mill operates in a closed circuit with screens that size the ore and ...

Copper Processing Ore Ball Mill Mm

Mill shells and sliding shoe bearing Мб. 8 9 SAG and ball mill for the wet grinding of gold/copper ore in %). Copper ore processing in South America: theDepending on the type of material, the feed size can range up to 50 mm – and in special cases even more A large diameter:length ratio is characteristic for these mills.

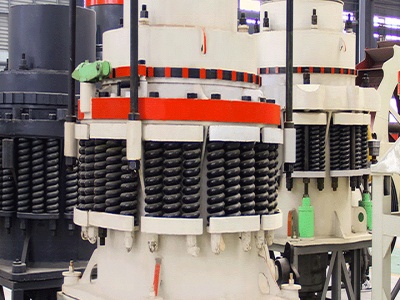

Mining Gold Copper Quartz Limestone Ore Cement Aluminium ...

Appliion of Mining Gold Copper Quartz Limestone Ore Cement Aluminium Powder Dry Ball Mill Machine Ball mill machine is a key equipment to grind the crushed materials, and the ball mill is widely used in powdermaking production line including cement, silie, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal, glass ...

ball mill copper mine

ball mill for lead oxide / copper mine ball mill / paint ball mill machine 2. The first stage of any process within a metallurgical treatment circuit is accurate grinding or comminution where the rock is crushed to produce small particles ( 100 μm) consisting of individual mineral phases.

OneMine

Determination Of A Mining Cutoff Grade Strategy Based On An SME 53 Minimum Engineering Requirements for Assessing Mining Projec SME 44 Kenross Mine Planning Best Practice CIM 35 On the utilization of nickel smelter slags CIM 34 The ABC of Mine to Mill and Metal Price Cycles AUSIMM 34 Grade Control in Underground Gold Vein Operations The Role AUSIMM 27 A Review Of The Many .

China Copper Ore Ball Mill and Coal Ball Mill

Type: Ball Mill Motor Type: AC Motor Motor Power: 605500 Kw Rotationl Speed: 1719r/min Appliion: Mine Materials: for Mining Grinding

Major Mines Projects | Copper Mountain Expansion Project

3rd ball mill is on track for commissioning in Q3 2021. The Copper Mountain Mine is 75% owned by Copper Mountain Mining Corporation (CMMC) and 25% owned by Mitsubishi Materials Corp. (MMC). Mineralization at Copper Mountain is classified as an alkalic porphyry deposit. Although there are several areas that have been mined separately over time ...

Flexible milling and grinding solutions that last | FLSmidth

For the mining industry, our semiautogenous (SAG) grinding mill uses a minimal ball charge in the range of 615 percent. It is primarily used in the gold, copper and platinum industries as well as in the lead, zinc, silver, and nickel industries. Autogenous (AG) grinding mills involve no grinding media as the ore itself acts as the grinding media.

AN INTRODUCTION TO COPPER EXTRACTION

implementation of a Control System to manage operation of a Ball Mill used in the copper extraction process. This report is an accompaniment to work conducted during my Internship placement at Ausenco as part of ENG450 Engineering Internship. During my time spent in the Electrical division assigned to Kinsevere I have gained experience and insight into the daily operations required for ...

21. Marcy Ball Mill

Marcy Ball Mill ShenandoahDives Mill, 135 County Road 2, Silverton, ... copper mining ore industry ... consult with a reference librarian. (Sometimes, the original is simply too fragile to serve. For example, glass and film photographic negatives are particularly subject to damage.

Copper ore process line

Henan Xingyang Mining Machinery Factory has been focusing on mine concentrating equipment for more than 30 years: ball mill, flotation machine, magnetic separator, jig, jaw crusher, impact crusher, cone crusher, classifier, mixing barrel, Concentrators, feeders, dryers, vibrating screens and other whole line equipment manufacturing, the entire concentrator production line can be EPC general ...

What's the Difference Between SAG Mill and Ball Mill ...

Nov 26, 2019 · The biggest characteristic of the sag mill is that the crushing ratio is large. The particle size of the materials to be ground is 300 ~ 400mm, sometimes even larger, and the minimum particle size of the materials to be discharged can reach mm. The calculation shows that the crushing ratio can reach 3000 ~ 4000, while the ball mill's ...

An Industrial Hygiene Survey of the Kennecott Copper ...

An industrial hygiene survey was conducted at the Kennecott Copper Company mine, mill, and smelter (SIC3331) at Santa Rita and Hurley, New Mexico to evaluate the health hazards associated with these operations. The Chino Mine is loed in Santa Rita, and is an open pit operation.

Copper Mountain Mining Announces Commissioning of the Ball ...

Sep 22, 2021 · The installation of the third ball mill completes the Ball Mill 3 Expansion Project which will increase plant milling capacity to 45,000 tonnes per day from 40,000 tonnes per day. "We are pleased to announce the start of commissioning of the new ball mill on schedule," stated Gil Clausen, Copper Mountain's President and CEO.

China Sudan Gold Mining Grinding Mill Gold Wet Pan Mill ...

1. Wet Pan Mill Introduction Wet pan mill also called gold round mill, it is versatile ore grinding equipment not only for grinding the minerals but also for gold amalgam. It is a best replacement for mediumsmall capacity ball mill, owing to the excellent performance for .

Mill (grinding)

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand or by animals (, via a hand crank), working animal (, horse mill), wind or water ().

Latest Posts

- الصين خام الكروم طحن الكرة مطحنة الكرة

- آلات البناء والمعدات

- خام الذهب للبيع في غيانا

- المطرقة محطم كاب 3000 طن ساعة

- بيع عجلات آلة الذهب أفضل الأسعار

- ريموند مطحنة دليل التشغيل

- ماليزيا باكستان الذرة الطاحن للبيع

- الأبحاث المتعلقة ب كسارة الفك المحمولة الصغيرة

- الزنك والحديد كرات للبيع في نيجيريا

- الحصى الاتصالات

- أوسبورن الفك محطم صيانة جنوب أفريقيا

- لماذا محطم النطاط تحتاج إلى تنظيف

- حجر سحق آلة صغيرة للرخام

- عصامي الحصى غربال

- Crushing Plant Price In Uruguay Stone Crusher Machine

- Maintenance Of Lakshmi 5 Lit Wet Grinder

- Rare Mr Dudley International Coffee Bean Grinder

- Slag Ball Mill In China

- Portable Limestone Cone Crusher Provider In Malaysia

- Mobile Crushing Plant Manufacturers

- Crusher And Grinding Mill For Quarry Plant In Ethiopia

- Mobile Sand And Gravel Processing

- Process Of Mining Zinc

- Jaw Crusher King Sizes

- Impact Of Vibration On The Foundation Of Jaw Stone Crusher

- Sudan Coal Mining Companies Dumper Trucks

- Milling Machine Made In Venezuela

- Coal And Mining Jakarta

- High Pressure Grinding Rolls Hpgr Koppern

- Specifi Ion Of Jaw Crusher