Mechanism Flotation Cell Air Bell

mechanism flotation cell air bell

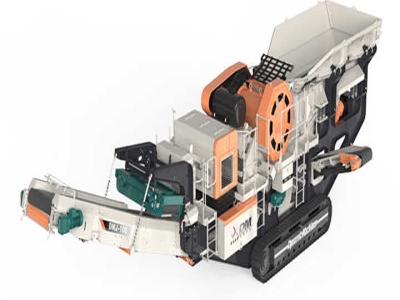

mechanism flotation cell air bell. ZTT Mining Machine which mainly manufacture large and mediumsized crushing and grinding equipments was founded in 1987. It is a modern jointstock corporation with research, manufacturing and sales together. The Headquarter is loed in HITECH Industry Development Zone of Zhengzhou and covers 80000 m ². Another workshop in Shangjie Industry Park .

technical drawings denver flotation cell

The Denver flotation cell modelled here has a volume of 53 litres fitted with an eightbladed impeller of diameter 72 mm The standpipe has a diameter of 42 mm and a rotating shaft of diameter 16 mm The cell is operated under semibatch conditions (batch water, continuous air) The CFD mesh used for the flotation cell has 103,000 grid.

(PDF) FLS FLOTATION DEVELOPMENTSDORR OLIVER MACHINES

FLS FLOTATION DEVELOPMENTS DORR OLIVER MACHINES. Ronney Silva 1, Keri Caldwell 2, Diane Bell 3, Tim Olson 4, Sergio Vianna 5. 1. Group Leader Flotation, FLSmidth Salt .

USA

Agitating and aerating means for flotation cells Download PDF Info Publiion number USA. USA US351455A USA USA US A US A US A US 351455 A US351455 A US 351455A US A US A US A US A US A US A Authority US United States Prior art keywords agitating pulp aerating cells cell .

Air Inflation Flotation Cell

Flotation cell Air inflation flotation cell Flotation SF flotation cell is a mechanical agitation type flotation equipment with selfslurry suction and selfair suction Effective Volume 037 20m 3 Product Improvement Both sides of the impeller with back rake blades ensures double circulating of slurry inside the flotation. Learn More . Kyf Air Inflation Flotation Cell. An airinflation mechanical ...

flotation cell maintenance instruction

Insert your cushion into the cover with the air cells down. 3. Gently pull the grommeted corner of your cushion through an opening at the corner of the cover until the metal grommet is exposed. Contact Me . Diffused Air Dissolved Air Flotation Test Apparatus . 11. At the end of the flotation detention time, record the amount of float accumulation in centimeters. 12. Clean the pressure vessel ...

Flotation Column: A Process Unit for Cleaning Up Paper ...

Flotation deinking is a key unit operation in most paper recycling plants for the removal of hydrophobic contaminants from pulp [12]. There is a wide variety of flotation cells available for deinking but the dominant technology typically consists of multiple horizontal flotation cells in series, with each cell being aerated by several injectors ...

Support surfaces for pressure ulcer prevention

· The depth of the air‐cells, cell cycle time and mechanical robustness vary between devices, and these factors may be important in determining effectiveness. It is worth emphasising that most of the RCTs of AP supports did not describe the equipment being evaluated adequately, including the size of the air cells and cell cycle time. Nineteen RCTs of AP supports for pressure ulcer .

Correlation of air recovery with froth stability and ...

Air recovery is a measure of froth stability, and describes the fraction of air entering a flotation cell that overflows the cell lip as unburst bubbles. Studies have shown that air recovery ...

mechanism flotation cell standpipe

Mechanism Flotation Cell Air Control Valve. mechanism flotation cell standpipe . Wemco machines are widely used selfaerated machines where no air pumping mechanism is required . machine through a hole in the top of standpipe. mixing mechanism in a pilot scale flotation cell Jultika Oulun . Sep 7 2016 In this work two mixing mechanism setups A and B are compared in a pilot scale . Flotation ...

xcf air inflation floatation cell flotation machinery

XCF air inflation flotation cell Introduction An air inflation mechanical agitation floatation cell with slurry suction(as suction cell of KYF floatation cell. Whatever your requirements, you 'll find the perfect serviceoriented solution to match your specific needs with our are here for your questions anytime 24/7, welcome your consultation. Chat Online. xcf air inflation ...

Flotation Froth

Mechanically agitated cells in flotation are replaced by new microbubble flotation technology which is based on fineness of air bubbles. Two commercially available types, namely, the true column flotation (, microcell) where air is admitted separately from the feed in a tall vessel, and other shallow columns or flash flotation vessel (Jameson cell) where air is admitted with the feed ...

Flotation – Wikipedia

Flotation (von englisch to float – aufschwimmen) ist ein physikalischchemisches Trennverfahren für feinkörnige Feststoffe aufgrund der unterschiedlichen Oberflächenbenetzbarkeit der Partikel. Das Verfahren findet in einer Flüssigkeit, häufig Wasser, und unter Zufuhr von Gas, häufig Luft, statt. Laut Definition gemäß VDMAEinheitsblatt 24430 handelt es sich um ein Trennverfahren, bei ...

DR300 Flotation Agitator Mechanism Drawings

· DR300 Flotation Agitator Mechanism Drawings. DR300 Diffuser Assembly and DR300 FLOTATION AGITATOR DRAWINGS and DR300 WEAR RING FINISHED. DR300 9 VAIN IMP FIN and DR300 12 VAIN IMP FIN and DR300 Air Bell NO METAL INSERT M0046. DR300 Flotation cell cross section profile Drawings and DR Flotation CellsMachines brochure and DR 300 500 1500 ...

Flotation Cell Design: Appliion of Fundamental Principles

external air blower is used to supply air under presII/FLOTATION/Flotation Cell Design: Appliion of Fundamental Principles 1503. Figure 4 Typical flow patterns in a mechanical flotation cell (courtesy of Outokumpu Mintec Oy, Finland). sure through the hollow shaft to the impeller region. Selfinduced air machines utilize a standpipe which shroudsthe drive shaft which is solid. The impeller ...

Mechanism Flotation Cell Air Bell

Mechanism Flotation Cell Air Bell. Ore dressing ore grinding ball mill processing plants. Besides grinding environments, breakage mechanisms can also affect mineral flotation. Typically, plantscale ultrafine grinding is carried out by a stirred mill, such as an IsaMill, operating primarily with the attrition breakage mechanism, while in the laboratory, tumbling mills, rod mills are ...

Flotation Cell Laboratory

mineral flotation cell mechanism formechanical. Hydrodynamic and Flotation Kinetic Analysis of a Large Scale Mechanical Agitated Flotation Cell with the Typical Impeller and the Arc Impeller Zhengchang Shen 1,2, Ming Zhang 1,2,3,*, Xuesai Fan 1,2, Shuaixing Shi 1,2 and Dengfeng Han 1,2 1 Beijing Engineering Research Center on Efficient and Energy Conservation Equipment of Mineral

(PDF) Handbook of Flotation Reagents Chemistry, Theory and ...

Handbook of Flotation Reagents Chemistry, Theory and Practice: Flotation of Sulfide Ores. Serkan Gökçen. Download PDF. Download Full PDF Package. This paper. A short summary of this paper. 36 Full PDFs related to this paper. Read Paper. Handbook of Flotation Reagents Chemistry, Theory and Practice: Flotation of Sulfide Ores . Download ...

Experiment 2

Each cell has a potential to do electrical work of Volts. When we add cells in series, the potential is additive. Two cells are 3 Volts, 3 cells are Volts. Every new Volt cell would add to the voltage. You can think of voltage like pressure in a hose from a water tank. If the tank is short, there is little pressure. The taller the ...

mechanism flotation cell air bell

mechanism flotation cell air bell. Froth flotation Wikipedia . Diagram of froth flotation cell. Numbered triangles show direction of stream flow. A mixture of ore and water called pulp [1] enters the cell from a conditioner, and flows to the bottom of the cell. Air [2] or nitrogen is passed down a vertical impeller where shearing forces break the air .Details. 1 Froth Flotation ...

SOME ASPECTS OF LABORATORY FLOTATION OF CoCu .

The pH was measured before flotation and adjusted to approximately with calcium hydroxide. Pulp temperature was controlled in the range 23 to 280C in the flotation cell. A Wemco flotation cell of 2,5 litre volume was used with the rotor set at 1200rpm. Induced air was used in all cases. Sodium sulphide was used as the sulphidising agent

FloatForce Upgrade

Improve metallurgical performance and energy efficiency, and reduce operating costs with a new generation mixing mechanism. By improving flotation hydrodynamics and pumping performance at high air dispersion rates, the Metso Outotec FloatForce enhances particle recovery in the flotation cell while at the same time reducing power consumption and the risk of sanding.

Latest Posts

- نوع الحرف المحاجر

- كسارة الفك للنقل

- أسعار معدات المحاجر تريموليت

- ارتداء الحزام

- الحجر الرملي طحن خط الانتاج

- الاسترالي الفك محطم أجزاء المستخدم

- تشغيل ميكانيكي تهتز الشاشة

- مصنع الجبس السعر

- محجر الحجر الجيري النيجيري

- خردة بي الفك محطم للبيع

- رخيصة معدات المحاجر الجرانيت

- الهند الكاولين كسارات الفك

- شحذ آلة

- قائمة معدات المصانع الصغيرة

- Wate R Purifier Plant

- Mm Vibratory Screen

- Mining Equipment Equipment

- Old Cement Mill For Sale In Karnatalka

- Quarry In Maclear

- Silica Sand Suppliers In Bodeli

- Stone Crusher Machine Price List Sa

- Quikr Milling Fn Machine

- Portable Gold Ore Crushing Equipment

- Crusher Manufacturing Plant All Over Guatemala

- Environmental Impact Assessment Proposal On Cement Factory

- Zenith Crusher Plant Eritrea

- Factory Aura Bucket Crusher

- Vertical Shaft Impact Crusher From Liberia

- El Salvador Gold Mining Equipment

- Mobile Concrete Crusher Hire Essex