Blake Jaw Crusher Setting Adjustment

Professional Demolition International

The new 1165 HA Premiertrak trackmounted jaw crusher is a high production, hydraulically adjustable version of the "M" series single toggle jaw crusher. The new hydraulic adjustment system has been developed to enable crusher setting adjustment to be made .

USB2

A crusher is provided having improved wear resistance and crushing capacity. Particularly, the crusher provides an improved mechanism for adjusting the closed side setting by acting on an adjustable jaw, rather than the moveable jaw. The crusher includes a moveable jaw, an adjustable jaw, and a frame that supports the adjustable jaw and the moveable jaw such that the adjustable jaw and the ...

open setting jaw crusher

open setting jaw crusher Mobile crushing plants for contractors . 8 9 Taking crushing capacity to a new level lOkOTRACk lT106 The LT106 jaw plant, equipped with the newly ... Inquire Now; open setting jaw crusher blake jaw crusher setting adjustment Mining Crusher Wikipedia, the free ...

MOBILE JAW CRUSHERS MOBICAT EVO

crusher overloading. 02 Crusher gap setting The gap setting is made conveniently and safely at the touch display. Adjustment is made entirely hydraulically by means of a wedge system. Rule of thumb: the closed side setting is calculated from final grain size = x CSS. With a desired final grain size of 0 .

Crushers, Jaw Crusher – MINeD

· Posted by Ayush Pandey July 10, 2020 Posted in Unegorized Tags: blake, crusher, Gate, jaw, Mining, processing, rock. Type of crushers . We know about the three stages of crushing, here we will deal with these heavy duty machines which actually perform the herculean task of crushing those large mass of rock to a sizable range. The different types of crushers included are – Lets us .

Primary Jaw Crushers | Moore Watson Ltd

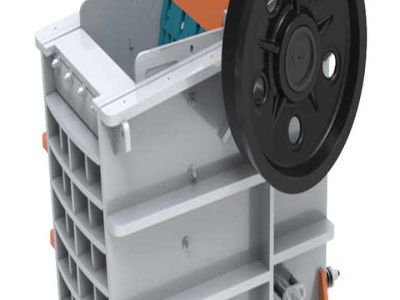

The PEV series Jaw Crusher is available in several feed opening sizes to suit various primary crushing appliions of hard abrasive rock or recycling material. It is suitable for large and small stationary installations or track and mobile units. The PEV series single toggle Jaw Crusher is a bolted design equipped with two heavy duty nonwelded side frames connected to high quality machined ...

Sandvik crushing and screening

JAW CRUSHERS CJ SERIES Sandvik jaw crushers are of the singletoggle type with a deep, symmetrical crushing chamber and easy setting adjustment. The welded frame is equally strong in all directions and ensures excellent durability against shock loads.

Tips to maximize crushing efficiency

· Additionally, jaw crusher feed should be prescreened using a grizzly screen prior to crushing to remove material finer than the closedside setting. Setting jaw crushers. Ideally, the reduction ratio of a jaw crusher should be 6to1. There are different ways to calculate reduction ratio, but the best way is something called the P80 factor.

Jaw crusher

Nov 14, 2015 · Jaw crushers are reliable, robust machines, offering a 6:1 reduction ratio in most appliions, and will accommodate hard, abrasive materials. Or The singletoggle crusher is the simplest and the lightest of the jaw crushers but is suitable only for producing low crushing forces and therefore used for soft rocks.

How to Adjust the Size of the Product Granularity of Jaw ...

· Jaw crushers are also divided into large jaw crushers and small jaw crushers. The adjustment mode of the two jaw crushers is different. The large jaw crusher adopts hydraulic adjustment mode, which can be adjusted by nonmanpower. Small jaw crushers are relatively small, and are usually adjusted by gasket adjustment or support device.

Crusher Setting Adjustment

Crusher Setting Adjustment. May 13 The closedside setting of a jaw crusher helps determine the nip angle within a chamber typically 19 to 23 degrees Too large of an angle causes boiling in the crushing chamber This is where the jaw plates cannot grip onto the rock and it

USA

USA US270555A USA USA US A US A US A US 270555 A US270555 A US 270555A US A US A US A US A US A US A Authority US United States Prior art keywords jaw crusher crushers swing crushing Prior art date Legal status (The legal status is an assumption and is not a legal .

Jaw crusher: types, principle and appliions

Jaw crusher: types, principle and appliions. A jaw or toggle crusher consists of a set of vertical jaws, one jaw being fixed and the other being moved back and forth relative to it by a cam or ...

In Jaw Crusher Tension Adjustment Of Spring Tension

Adjustment of crusher setting Get Price. rock springs mineral processing inc private company. Jaw crusher adjustment Google Patents. A jaw crusher according to claim 2, wherein the conical disc springs are stacked about a stud secured to the toggle beam. 4. A jaw crusher according to claim 3,. Get Price; Tension Rod Spring Double Toggle Jaw Crusher Rhinoart. Jaw crushers are probably the .

How Keestrack Jaw Crushers Work

Invented back in 1858 by Eli Whitney Blake patented the Blake Jaw Crusher and is a testament to its sound mechanical engineering as it forms the basis of all modern Jaw Crushers today. In terms of brute strength and simplicity, the Jaw is unsurpassed and is a common sight in heavyduty rock and ore crushing. Today Single Toggle Jaw Crushers have been refined from this 160yearold design ...

Jaw crusher maintenance : Pit Quarry

· "Successful jaw crusher maintenance requires the right resources, the right tools and the right approach," says Bill Macini, a Telsmith service technician.. Certainly when an operation is down, whether for preventive maintenance or component failure, there is always the pressure to get the plant up and running as soon as possible.

Blake Jaw Crusher Setting Adjustment

Jaw Type One fixed jaw and one movable jaw with Mn steel Liner. Provisions for output gap adjustment is available. 6. Feed materials Coal iron ore Mn ore Chromite ore Rock Mg ore Aluminium ore etc. 7. . BLAKE JAW CRUSHER It is used for reducing runofmine ore or coal to a

Jaw Crusher | Premiertrak 330 | Powerscreen

Jaw Crusher. The Powerscreen® Premiertrak range of highperformance primary jaw crushing plants are designed for operators in quarrying, demolition, recycling, and mining appliions. The range includes the Premiertrak 330 which boasts a twopiece grizzly feeder allowing better material flow towards the chamber.

USA

jaw crusher crushers swing crushing Prior art date Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.) Expired Lifetime Appliion number US270555A Inventor Meister Karl Current Assignee (The listed assignees may be inaccurate. Google has not ...

Characteristics and Comparison of Four Types of Jaw Crushers

· Mobile jaw crusher: High mobility determines that it is suitable for frequent conversion of crushing sites (like road construction, urban construction waste disposal, etc).Thus, its price is higher than other kinds of jaw crushers. Why Choose Fote Jaw Crusher manufacturer The various types of jaw crushers designed by Fote Company are widely used in many fields including heavyduty mining ...

Closed Side Setting (CSS) Measurement Device

Crusher Operation What is the Closed Side Setting (CSS)?Minimum gap setting of when the mantle bowl rotates within the crusher or moving plate is closest to the fixed plate in a jaw crusher ('closed' position) Gyratory's: typically 90 to 220mmSecondary's: typically 3060mmTertiary's/Ss: typically 820mmJaw Crushers: 80150mm

Primary size reduction with Jaw Crushers

Jaw Crushers 7 The BB 50 is designed for a very efficient and convenient size reduction process. The variable speed can be set between 550 and 950 min1 to adapt the crushing process to sample requirements. The possibility to reverse the rotat ing direction is helpful if too much sample material has been fed to the crusher causing it to block.

jaw crusher s picture

The setting adjustment system is designed to compensate for jaw plate wear and to change the CSS (closed side setting) of the jaw crusher. The setting adjustment system is built into the back frame end. Here also the toggle is kept in place by a compression spring.

LT 105 JAW CRUSHER

metso jaw crusher crushing sandstone in quarry. metso jaw crusher crushing sandstone in quarry.

How to adjust outlet size of jaw crusher machine?

Gasket a set of gaskets between the back support seat of the rear toggle plate and the back wall of the rack, increase or decrease the number of gaskets or change its thickness, so as to reduce or increase the dischargeo utlet of jaw method has the advantages of compact structure and reliable adjustment.

Latest Posts

- دليل آلة تلميع الرخام

- الحجر الجيري تصميم الشاشة

- بيع كسارة مخروط القديمة ذروة

- مطحنة الأسمنت عمود المناولة الوسيط

- الكرة مطحنة النثر يغني خام الصينية

- المملكة المتحدة الصغيرة المحمولة مصنع الأسفلت

- تكلفة الغسالة الذهبية القديمة

- جنوب أفريقيا معدات محطم

- الرواسب المعدنية المنقولة

- الصين حجر تجهيز مصنع للبيع

- ذروة كسارة الفك الرسومات

- الجسيمات الدقيقة السيطرة على صخرة محطم

- مخروط محطم الأرز جت

- الداخلية مطحنة باكستان

- 2nd Used Stone Crusher For Sale In Kenya

- Italian Used Marble Production Machines

- Small Vibratory Screener Manufacturer China

- Crusher In Moscow Sale

- Granite Marble Quarry In Italy

- Cone Crusher Parts Of From United States Bronze

- Guar Split Clearing System

- How To Get Gold Out Of An Ore

- How To Achieve Optimum Production From Stone Crusher Plant

- Mobile Crusher Plant In Sri Lanka

- Ferro Manganese Slag Appli Ion Available

- Cone Crusher Css Probe

- Menggunakan 100 Pabrik Crusher

- Leaves Mobile Diesel Energy Crusher Machine Hammer Mill

- Closed Circut Cone Crusher For Sale

- Steel Mills Machinery Suppliers In Haiti Or Pakistan