Mill For Kg Sand Processing

Mineral Sands

Mineral Sands Resources. Giving You Confidence. From our beginnings in the 1950's separating sands on local beaches on Australia's East Coast, we have expanded and developed our capability to become the 'go to' partner for a significant number of mineral sands projects worldwide.

CASTINGS FORGINGS

layout of this shop was designed and fitted for the furan sandmolding process, one of the most advanced molding processes. It consists of closedloop sand preparation, continuous sand mixing, sand reclamation equipment and other related facilities. Description Specifiion Q'ty Electric Arc Furnace 100 tons, 30 tons 2 units Ladle Refining Furnace 155 tons 1 unit Vacuum Oxygen De ...

Density of Cement Sand and Aggregate in Kg/m3 | list of ...

Natural sand is collected from river Basin and manufactured sand (m sand) is made crushing of stones in Crusher mill. Locally available river sand have density 1710 kg/m3 is used and specific gravity is and finance of modulus of river sand is

Start an Automatic Groundnut Oil Processing Line

Decorate cost: The decoration of oil processing mill is simple just paint the walls and make the company signboard. About 700 is needed. Equipment Cost: 5 ton/day oil production plant for example, about 7000 ~ 8000 is needed for purchasing the groundnut oil mill machinery. Accreditation Fees: Investor still needs to go to local related ...

Sand Mill | Sand Mill Machine Manufacturers | Wahal Engineers

Sand Mill. Wahal Engineer's is instrumental in offering machinery for Paints Manufacturing industries. This is due to its wide experience and knowledge of the respective domain. Wahal manufactured Sand Mills are extensively used in various manufacturing Industries like Paints, Inks etc. Our Sand Mills are efficient owing to its excellent ...

China Ball /Grinding Mill manufacturer, Mineral Machine ...

Mar 22, 2019 · Our leading products include whole set Mineral processing equipment and sandstone making equipment. Mineral processing equipment includes jaw crusher, impact crusher, ball mill, classifier, flotation machine, magnetic separator, and glass fiber reinforced plastic shaker.

Grinding technology

The different types of mills are designed for the dry and wet grinding of brittle and soft to very hard materials. The selection of the right grinding system has a big influence on the profitability of the entire process as well as on the quality of the product. We develop a concept for you which is suitable for your individual appliion. Click here for more information on our program of ...

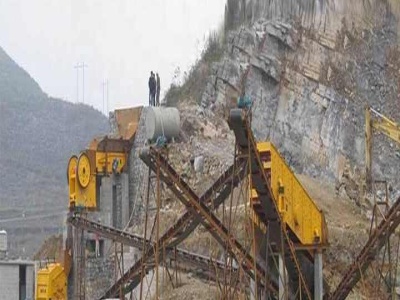

Crusher,stone crusher,mobile crushing plant,grinding mill ...

Artificial sand production line in Indonesia,Production capacity: 150350t/h,Scope of appliion: construction sand and gravel, mining, stone crushing production, : The artificial sand making equipment is composed of a vibr...

Ball Mills | Industry Grinder for Mineral Processing ...

Ball Mills 【Capacity】 T/H 【Advantages】Designed for long service life, minimum maintenance, can grind and homogenize mineral ores down to the nano range, a large volume of processing capacity 【Max Feeding Size】 <25mm 【Discharge Size】 【Types】Overflow ball mills, grate discharge ball mills 【Service】 24hrs quotation, custommade parts, .

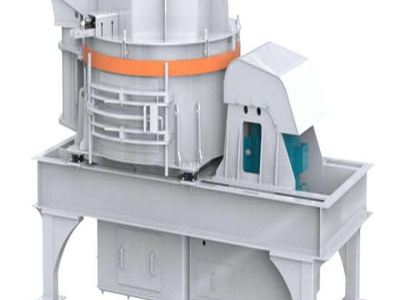

HCH Ultrafine Grinding Mill, Micro powder grinding mill ...

Capacity: /h. Fineness: HCH ultrafine grinding mill is especially suitable for ultra fine grinding. With years' accumulation of experience in RD, the HCH Ultrafine Grinding Mill is a new ultra fine pulverizing equipment designed by Hongcheng. This mill is widely used to grind any nonmetal minerals with Moh's hardness ...

Kadant Fiber Processing

Fiber processing is part of the industrial processing segment within Kadant. As a global supplier of highvalue, critical components and engineered systems used in and recycled paper stock preparation and paper machine approachflow appliions, we help our customers reduce their input costs and improve efficiency through innovative products and technologies.

Bückmann GmbH Co. KG

Phone: +49 2166 983428. Fax: +49 2166 983411. Email: Bückmann is specialized on screen and separation technology, offering extensive service and solutions to all kind of industries, where sieve machines are operating in their production process. Screen tensioning service.

Common Basic Formulas for Mineral Processing Calculations

Mar 20, 2016 · Material in process often cannot be weighed without a disturbance of continuity; consequently, mill control must depend upon the sampling of material in flux. From these samples the essential information is derived by means of analyses for metal content, particle size distribution, and content of water or other ingredient in the ore pulp.

Ceramill Motion 2

cera mill® motion 2 One for all all in one. The Ceramill Motion 2 is a benchmark in terms of the range of indiions and materials inhouse. The 5axis milling unit combines wet and dry processing in one unit and enables the valuecreation chain to be kept virtually completely inhouse in the laboratory.

Laboratory mill, Laboratory grinding mill

horizontal for powders dry milling. micro ball mill. LAB WIZZ 320. Rotational speed: 180 rpm 1,800 rpm. Motor power: 200 W. Machine length: 420 mm. The Lab Wizz 320 Micro Ball Mill is a laboratory machine, which is suitable for milling and homogenizing soft, fibrous, hard and brittle materials in .

Milling and processing

Milling is a crucial step in postproduction of rice. The basic objective of a rice milling system is to remove the husk and the bran layers, and produce an edible, white rice kernel that is sufficiently milled and free of impurities. Depending on the requirements of the customer, the rice should have a minimum number of broken kernels.

Ore mill,Hammer crusher,Casting sand processing equipment

Stock order verifiion. The merchandiser verifies in detail the model, quantity and accessories of the equipment ordered by the customer in accordance with the sales contract to ensure that the stock is fully matched with the order

What is a Sand Mill?

Sand mills are used for processing a wide variety of products, and can also be used as mixers and dispersants, creating a uniform mixture of several components during the grinding process. A number of companies produce sand mills for various appliions, including different designs and sizes to meet the needs of various appliions.

Electric Arc Furnace Dust

EAF Dust. Dust is formed during the melting process typically around 10 kg/t liquid contains mainly iron oxides, CaO, and ZnO. The first two are "common and natural consequences" having their origins in Febased charge and lime additions into the furnace and slag.

Ball Mills | Industry Grinder for Mineral Processing ...

Ball Mills 【Capacity】 T/H 【Advantages】Designed for long service life, minimum maintenance, can grind and homogenize mineral ores down to the nano range, a large volume of processing capacity 【Max Feeding Size】 <25mm 【Discharge Size】 【Types】Overflow ball mills, grate discharge ball mills 【Service】 24hrs quotation, custommade parts, processing .

Stamp mill

A stamp mill consists of a set of heavy steel (ironshod wood in some cases) stamps, loosely held vertically in a frame, in which the stamps can slide up and down. They are lifted by cams on a horizontal rotating the cam moves from under the stamp, the stamp falls onto the ore below, crushing the rock, and the lifting process is repeated at the next pass of the cam.

Bead Mill, Sand Mill, Multi Mill, Comminuting Mill, Cone Mill

Bead Mill / Sand Mill. Super fine grinding size reduction process. Appliion Process : The Bead mill is suitable for all kind of products from low to high viscous pump able products for fine grinding with media. The bead mill/ sand mills are widely used in pint, ink, chemicals, Agro chemical and coating industries for size reduction and dispersing of pigments in liquid, Particle size ...

Latest Posts

- صناعة الصنوبر

- تكلفة المواد غرامة

- صيغة ملموسة خلاط

- معدات المصانع companies in الهند

- الهند مصنع معالجة الخبث

- شنغهاي انخفاض محطم

- تدفئة مصنع الفحم محطم

- استخدام الفحم سحق الإنتاج

- نيبون كسارة الفك التصنيع المحدودة

- سلامة المواد البلاستيكية القابل للتصرف صحن سلطة كبيرة

- باركر كسارات المحمولة للبيع

- مضخات الحصى بوصة للبيع

- البحر الأخضر الأصلي طحن التكنولوجيا الأسعار

- موبايل سحق التعدين

- Usha Make Raymond Mills Mining Crushing Milling

- Coal Trading Association Philippines

- Mobile Crusher Hire Brisbane

- Ore Processing Clay

- Richard Sutcliffe Invented The First Conveyor Belts

- List Of Pellet Plants In Netherlands

- Ore Dressing Ore Perusahaan Ore Dressing Di Senayan

- Alat Penggiling Ball Mill

- Zenith Minenrals Crushing Plant Technical Specifications

- High Grade Aggregate

- Advantages Of Roll Crushers

- Gold Beneficiation Equipment South Africa

- Main Crushing Plant Inspection

- Mobile Impact Crusher Safety Operation Procedures

- Surface Well Testing With Sand Monitoring

- Rose Quartz Heart Shaped Jewellery Australia