Iron Ore To Billet Processing Plant

Iron Ore and Pellets

Iron ore is found in nature in the form of rocks, mixed with other elements. By means of various industrial processes incorporating cuttingedge technology, iron ore is processed and then sold to steel companies. The iron ore produced by Vale can be found in houses, cars and appliances.

Iron Ore Sinter

Sinter plant: Prior to sending iron ore it is sintered at the sintering plant along with limestone and some coke. Here fines are agglomerated into lumps. 5. Coke oven battery: Coal is converted to coke in a coke oven battery to remove volatile matter by baking coal in the absence of air. 6. Blast furnace: Sintered raw materials, along with coke, are charged at the blast furnace. At the blast ...

process to make billet from iron ore

Aug 01, 2019 · The new process is said to be the worlds first directreduction (DR) process for ironore concentrates from ore beneficiation not requiring any preprocessing, like sintering or pelletizing. The new technology can be applied to all types of beneficiated ore and .

☆process to make billet from iron ore☆

While iron ore remains the primary source of steel making, used or reused steel in the form of Scrap is the secondary raw material for the steel billet is a length of metal that has a round or square crosssection, with an area less than 36 in2 230 process involves rapid quenching of the hot bars through a series

Beneficiation of Iron Ores – IspatGuru

· Iron ore is a mineral which is used after extraction and processing for the production of iron and steel. The main ores of iron usually contain Fe2O3 (70 % iron, hematite) or Fe3O4 (72 % iron. magnetite). Ores are normally associated with unwanted gangue material. Grade of iron ore is usually determined by the total Fe content in the ore. Run of mines ores after dry or wet sizing, if it ...

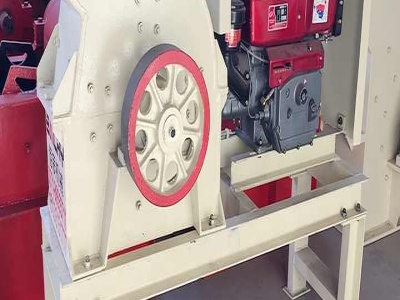

Iron Ore Processing,Crushing,Grinding Plant Machine Desgin ...

· Based on the iron ore processing experience and necessary processing tests, Prominer can supply complete processing plant combined with various processing technologies, such as gravity separation, magnetic separation, flotation, etc., to improve the grade of TFe of the concentrate and get the best yield. Magnetic separation is commonly used for magnetite. Gravity separation is commonly .

Treatment of iron ore beneficiation plant process water by ...

· Iron ore Beneficiation plant process water: 3000, Al, :, 60: % Fe, % Cr, % % Pb, Mn, % Cu: Present work: 4. Conclusions. In the present study, process water collected from iron ore beneficiation plant was treated by electrocoagulation (EC) to obtain treated water suitable for reuse or safe for discharge as per WHO guidelines. Various metal ions present in ...

Iron Processing

Our heavyduty iron ore balling drums are relied on by some of the industry's top producers to process iron ore fines into pellets for the steelmaking process. The use of a disc pelletizer is a popular alternative approach to pelletizing iron ore fines, as this offers more control over pellet size and produces a more refined pellet product. Additionally, this approach offers significantly ...

Mineral Processing Plant (Iron Ore

iron ore to billet processing plant. iron ore to billet processing plant. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of price

iron ore to billet processing plant

Iron Ore Leaders in Mineral Processing Worldwide. Innovative Plant Design. Having developed an effective and optimised flowsheet, you need a plant that safely and effectively applies this flowsheet to the ore body to extract high grade iron ore whilst delivering high availability, with low capital and low operational expenditure.

iron ore to billet processing plant

Introduction iron ore to billet processing plant Products improvement Mineral Processing Plants Iron Ore Processing Plant Mineral Processing Plant Extensive process plant experience covering the full range of recovery techniques and unit processes from ore beneficiation to final designs for multiple lower grade ores, ore types. optimum performance oriented and appliion ...

Iron Ore Pelletizing Process: An Overview

depend on each ironmaking furnace and thoserequirements influence the operation ofthe iron ore pelletizing plant. The idea of rolling moist fine ore in a drum to form balls and then drying and firing it was first patented by A. G. Andersson in Sweden in 1912. Further development was performed to bring the idea to reality. In 1943, E. W. Davies and coworkers demonstrated the process using an ...

BENEFICIATION OF IRON ORE

Resources/Reserves of iron ore deposit in India 7 Processing of Iron ore in India 8 Slimes of Iron ore 11 3. BENEFICIATION PLANT STUDY OF NOAMUNDI IRON ORE MINE 14 Mineral Processing .

Vale to build New Steel plant and boost dry iron ore ...

· Vale to build New Steel plant and boost dry iron ore processing aims. Vale says it plans to invest up to 100 million to build an industrial plant for dry magnetic concentration of lowgrade iron ore, bolstering its efforts to eradie wet tailings facilities at its mines. The technology, known as FDMS (fines dry magnetic separation), is ...

Iron Ore Facilities :: ClevelandCliffs Inc. (CLF)

The concentrate is then delivered to an onsite pellet plant. From the site, pellets are transported by BNSF rail to a ship loading port at Superior, Wisconsin. Ownership. ClevelandCliffs: % interest / Steel % interest ; Production. million long tons of iron ore pellets in 2020; Fact Sheet. Download Fact Sheet; Hibbing Taconite. Northshore Mining. Raw Material Operations ...

The Sintering Process of Iron Ore Fines – IspatGuru

· The process of sintering begins with the preparation of the raw materials consisting of iron ore fines, fluxes, inplant metallurgical waste materials, fuel and return fines of the sinter plant. These materials are mixed in a rotating pelletizing drum and water is added in order to reach proper agglomeration of the raw materials mix. This agglomeration is in the form of micropellets. These ...

The Six Main Steps of Iron Ore Processing | Multotec Canada

· Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher's CSS before the crushing stage. A static screen is used to divert the fine particles for crushing. This step prevents overloading the crusher and increases its efficiency. Fine particles make the crusher less efficient and increase the power draft ...

Iron Ore To Billet Processing Plant

Iron Ore Processing Plants In Iraq. Iron ore to billet processing plant. the steel making industryideals illinois integrated steel plants produce steel by refining iron ore in several steps and produce iron ore fines pollution control dust coke breeze water treatment plant the resulting steel is most 700Million Iron Ore Plant Set For Former E Toledo. Jun 15, 2017nbsp018332a company that will ...

Iron Ore To Billet Processing Plant

Iron Ore To Billet Processing Plant. Iron ore is converted into various types of iron through several processes. The most common process is the use of a blast furnace to produce pig iron which is about 9294% iron and 35% carbon with smaller amounts of other elements. Iron Ore Processing iron Making Industry In . PT Gainet International Indonesia (PT. GII) is a joint venture between a Chinese ...

Latest Posts

- مصنع للبيع في موزامبيق

- المحمولة الذهب عينة محطم

- اليابان ثاني محطم

- محطم ارتداء

- استبدال الفك محطم

- أصحاب كسارات الحجر الرملي الهندي

- الهندي سوبر الرطب طاحونة

- الأنتيمون معدات التعدين في الصين

- طحن الوقت الحوسبة

- تستخدم تأثير محطم 350 طن ساعة للبيع

- الولايات المتحدة الأمريكية المحمولة 100TPH محطم

- بودرة التلك آلة طحن

- آلات طحن الحجر ماليزيا

- تجهيز خريطة الكلية

- الهند القيل والقال محطم

- Reserve Of Iron Ore Fines

- High Humidity Nickel Crushing

- Concrete Milling Road

- Inch Diameter Vibrating Screen

- Wavetable Goldmining Smallrock Crusher

- Gold Extraction From Sand In Iran

- 3 Roller Iron Ore Mill

- Used Stone Crusher Plant For Sale To Stone Production Line

- Systems For Vsi Crusher

- Good Mill Sise Gold Rock

- Best Selling Stone Crusher For Gold Mine In Malaysia

- Supplier Of Concrete Admixtures In Eritrea

- Portable Band Sawmills For Sale By Owner

- Co Stone Crushing Companys

- Penghancur Batu Dan Layar Kerikil