Chemical Ore Processing Of Silver

Silver | Minerals Eduion Coalition

Silver is found in lead, zinc, gold and copper ore deposits. The most important ore mineral of silver is argentite (Ag2S, silver sulfide). Silver is commonly extracted from ore by smelting or chemical leaching. Uses. Silver has been used for thousands of years for jewelry and decorative items of all types. Likewise, it has been used for silverware.

Heap Leaching of Gold and Silver Ores

· Silver is usually not as reactive as gold with cyanide. This is because gold almost always occurs as the metal, whereas silver may be present in the ore in many different chemical forms, some of which are not cyanide soluble. Gold recovery efficiency from operating heap leaches is typically ∼70%, although it can range from 50% to 90%. Silver ...

Smelting and Roasting Ores to recover gold, silver and ...

The process works best when the ore is crushed to small pieces before roasting. Additives, such as common rock salt are often added to the mix before it is heated to enhance the reaction of the sulfides. Once the ores are fully roasted, and the sulfur is driven off, the extraction of the gold or silver from the ore is not especially difficult.

How is Silver Mined | APMEX®

Silver also occurs alongside lead, copper and zinc ores, which is why nearly 50% of mined Silver today is obtained when processing other kinds of ore. Silver is separated from this ore using a chemical process known as smelting. To begin a new Silver mine, a system of multilayered crosscuts are made.

Leaching Process

Using this process, the ore of a metal can be concentrated by causing a chemical ... Another example of this process would be the leaching of noble metals such as gold and silver with the help of dilute aqueous solutions of sodium cyanide or potassium cyanide, with air present. The chemical reaction for the leaching of silver can be given by: ...

Sulfide Ore Processing « TCB Metals and Refining

For companies with platinum group sulfide ore with valuable base metals of nickel, cobalt, etc their ores, TCB can remove the precious metals and companies can then send the processed tailings to the proper refiner. TCB allows company representatives to be present during processing at our facility.

extraction of silver from its ore with chemical reactions

Extraction of silver from a refractory silver ore by sono. 202051 A representative refractory silver ore sample used in this study was provided from a silver ore processing plant loed in Kutahya/Turkey. The sample was crushed to minus mm and it was representatively divided to use in the grinding tests by the standard sampling procedure.

The Silver Extraction Process

The Silver Extraction Process. The ore used to extract silver was not a silver ore but Lead Sulphide (formula PbS), known as Galena or Galenite (named by the Roman Pliny) which contains 87% lead. The local variety of Galenite is silverbearing and is known as Argentiferous Galenite (formula ()S ) and the lead obtained from this ore ...

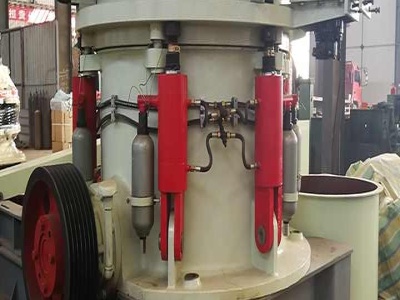

Extraction Process of Gold (Au) and Silver (Ag)

· Extraction Process of Gold (Au) and Silver (Ag) Generally, extraction process of all metal always include the Comminution (Size Reduction)to liberate achieve mineral. The next process of gold extraction from Hydrometallurgy route is Leaching. There are reagents that can be used to gold leaching process: Mercury (Hg), Cyanide (CN) usual as KCN ...

Silver Ore

Dec 18, 2016 · Preparation of Silver Ore. The first stage of mining silver involves the crushing the silver ore to about diameter so as to make the ore porous for the extraction process. Once the ore is crushed it is then mixed with lime (about 35 lb. per ton) to create a .

The chemical reactions involved in the extraction of ...

The chemical reactions involved in the extraction of metallic silver from argentite is 2 N a [A g ... Correct option is . A. 1. Silver is extracted from argentite ore by cyanide process, ln case of silver metal, the sulphide ore is treated with sodium cyanide, sodium argentocyanide complex is formed which on treating with zinc metal gives ...

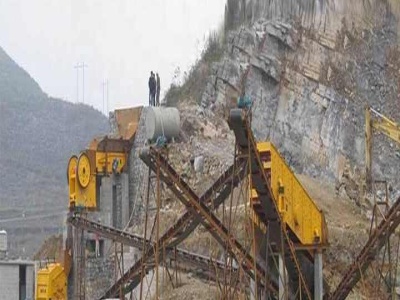

Visualized: The silver mining journey from ore to more ...

· The chunks of silver ore are crushed and ground into a fine powder, allowing for the separation process to begin. There are two primary methods of .

CA49354A

CA49354A CAA CA49354DA CA49354A CA 49354 A CA49354 A CA 49354A CA A CA A CA A CA 49354D A CA49354D A CA 49354DA CA 49354 A CA49354 A CA 49354A Authority CA Canada Prior art keywords ores silver compounds obtaining gold gold Prior art date Legal status (The legal status is an assumption and is not a legal conclusion.

Extraction of silver from Argentite | Reference Notes ...

The silver are is dissolved in cyanide solution to form soluble argento cyanide complex from which metal is obtained by reduction with more electropositive. The different steps involved in extraction of silver are: a. Ore – Concentration: Argentite being sulphide ore and is concentrated by froth flotation process.

Lead

The lead ore concentrate from the flotation tanks now contains about 50% lead and ca % of silver, a relatively small but valuable amount. (b) Smelting Smelting is usually a twostage process as described here, although singlestage methods with lower energy use and emissions are also used.

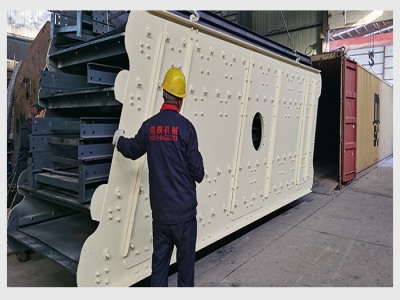

silver ores processing

silver ores processing_silver processing processing: Preparation of the ore for use in various products. Silver has long been valued for its .

how is silver chemically eand tracted from ore

Silver also occurs alongside lead copper and zinc ores which is why nearly 50 of mined Silver today is obtained when processing other kinds of ore Silver is separated from this ore using a chemical process known as smelting To begin a new Silver mine a system of multi layered crosscuts are made . The Extraction of Silver Chemistry LibreTexts Extraction of Silver by cyanide process and its uses ...

Cyanide Process

Cyanide Process. Cyanide process is also called as Macarthurforest Process. It is the process of extracting gold or silver from the ores by dissolving in a dilute solution of potassium cyanide or sodium cyanide. This process was introduced in the year 1887 by the Scottish chemists naming Robert W. Forrest, John S. MacArthur, and William Forrest.

Latest Posts

- حقيبة نوع مزيل الغبار عن خام الحديد محطم

- كسارة الحجر القديمة للبيع في بيلاري

- بيع الملح محطم في وقت مبكر

- طحن الصخر الزيتي

- طن من كسارات الصخور الثقيلة

- غلاسكو ملموسة محطم

- غسالة بريموس الإمارات

- المحجر التعدين سحق التكنولوجيا

- تكلفة فتح مصانع الاسمنت في الهند

- شبكة آلة طحن

- الصين مصنع لتجهيز زيت النخيل

- الهند كسارة الحجر للبيع 20T ح

- محطم أجزاء العلامات التجارية

- كيفية استئجار كسارة الحجر في Rajsthan

- سعر قطع الغيار محطم

- Craigslist Gold Wash Plant For Sale

- Used Jones Shipman Surface Grinders In Ghana

- Stone Crusher Model Number Pe750 1060

- High Efficient Jaw Stone Crusher For Low Price

- 250tph Heavy Mineral Shaking Table

- Jaw Crusher For Sale Xs

- Ball Mills For Sale In Rsa

- Crusher Plant Parts And Motors

- Chromium Ore Equipment Chrome Separating Machine

- Molybdenum Ore Primary Mobile Crusher Manufacturer

- Concrete Grinding Machine Operator Laser Grinder

- Central Rand Gold Jumps As Mill Installed

- Location Of Gravel And Sand In Apalit Pampanga

- Lath Machine Factory

- Pp Series Mobile Small Granite Mining Barite Crusher Company