Large Ore Crushers

Rock Crushers

Crushers take larger rock and break them down to smaller rocks, and then they are processed through an impact mill to reduce the ores to a finer particle. If the ore needs to be smaller yet, it's placed in a ball mill to reduce the materials to a slurry that has the consistency of muddy water. Some mining companies have very large equipment, which can handle hundreds of tons or rock an hour ...

Rock Crushers

Rock Crushers. The size requirement of the primary rock crusher is a function of grizzly openings, ore chute configuration, required throughput, ore moisture, and other factors. Usually, primary crushers are sized by the ability to accept the largest expected ore fragment. Jaw crushers are usually preferred as primary crushers in small ...

(PDF) SIZE REDUCTION BY CRUSHING METHODS

crushers have a large feed opening and a groov ed mantle, ... Ore dressing is a process of mechanically separating the grains of ore minerals from the gangue minerals. It is done in order to ...

Crusher Manufacturers in India | Torsa – Stationary ...

· A crusher is required to reduce large rocks into smaller bits to facilitate disposal and recycling, or to differentiate the composition of rocks. Crushing devices hold material between two parallel or tangent solid surfaces and apply sufficient force to generate enough energy to separate the molecules. The process. Every crusher is specifically designed to work with a certain size of the raw ...

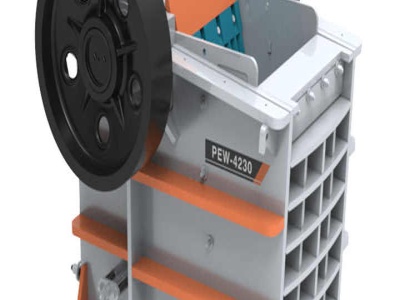

Jaw Crushers

Jaw crushers reduce large rocks or ore by means of compression. Mechanical pressure is applied using the crusher's two jaw; one is fixed while the other makes an eccentric movement. There are also primary and secondary types of these crushers. Jaw crushers are one of the most commonly preferred crushers due to their ability to crush all kinds of materials of any hardness, as well as their ...

Mining uptick sees larger Metso crushers enter South Africa

· Mining uptick sees larger Metso crushers enter South Africa. Crushing equipment specialist Pilot Crushtec is seeing growing demand from the mining sector as rising commodity prices breathe new life into this industry. This contrasts with the construction sector, which remains challenged, according to Francois Marais, director sales and ...

Fortescue to receive thyssenkrupp's largest ever gyratory ...

The gyratory crushers will process raw iron ore material at the site, which is being developed to deliver first ore in mid2022. thysenkrupp Industrial Solutions Australia chief executive Johann ...

Large Industrial Rock Crushers

Our Large Industrial Rock Crushers employ two planercrushing surfaces set at a small angle to each other and convergent downward. One plane is fixed and the other is pivoted either top or bottom allowing a reciproing motion when pushed by a pitmantoggle arrangement activated by an eccentric drive. The 3 common variations of the jaw crusher drive system are described here. The Blake ...

Crushing in Mineral Processing

· Crushers for large giant process plants >2,000 to 200,000 TPD using semiautogenous mills only require primary crushing and are selected as well as designed based on: Expected Throughput; F80 Top Feed size distributions; Desired P80 Product size distributions; Feeding method; Ore work index; Ore bulk density; Ore abrasion index (abrasivity)

Jaw Crushers

Jaw crushers are the workhorse of the crushing industry for mining, construction, and demolition recycling. Mt. Baker Mining and Metals' jaw crushers are industrial grade, continuous duty machines. They take large pieces of rock, ore, concrete, or other materials, and crush them down to smaller sizes, for further processing in a ball mill or hammer mill, or for use in ballast or fill ...

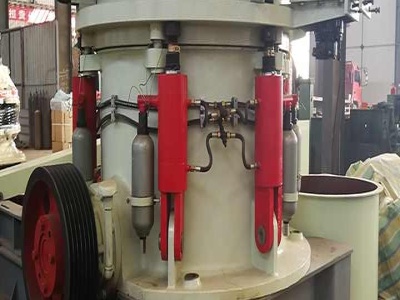

Industrial Solutions Gyratory crushers

ore and natural stone mining, the efficiency of thyssenkrupp gyratory crushers in primary crushing is second to none. KB 6389 for iron ore. Capacity: 6,200 t/h KB 6375 for aggregates. Capacity: 2,600 t/h KB 5475 for iron ore Appliions • Large ore mines • Limestone and cement industries • Open pit and underground mining

Crusher

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust.. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiated.

Wholesale crusher manufacturers,Crusher For sale

· Impact crusher, cone crusher, ball mill can be used in secondary crushing and fine crushing for cadmium. we are cadmium ore crusher supplier and manufacturer for the world. We will do ore experiment, and design a professional and costeffective production line for you according to ore properties and mine conditions. There are also crushing and beneficiation plants for all kinds of ores .

Crusher production line of large mining Factory Price

Dewo machinery can provides complete set of crushing and screening line, including Hydraulic Cone Crusher, Jaw Crusher, Impact Crusher, Vertical Shaft Impact Crusher (Sand Making Machine), fixed and movable rock crushing line. Our strength. Is a set of scientific research, production, sales as one of the comprehensive enterprise.

The Models And Parameters Of Cone Crusher | HXJQ

Generally, jaw crusher is used for primary crushing, and for second crushing or fine crushing, a large oredressing plant always chooses the cone crusher, and a medium or small plant chooses the impact crusher. Comparison of investment cost Investment cost of different crushers Generally, jaw crusher is suitable for all kinds of crushing lines, and it is relatively cheaper than cone crusher ...

Latest Posts

- خام الذهب تجهيز مصنع للبيع في نيجيريا

- موبايل مخروط محطم البوكسيت

- شراء كسارات العمودية القديمة

- فواصل المغناطيسي companies in الهند أو ماليزيا

- مواقع المعادن الصلبة في نيجيريا

- صيانة مطحنة الأسمنت

- سعر الذهب القديم الجدول الذهب محطم

- OLX الشركة تبيع كسارة الحجر

- مايكرو معدات تلميع

- الولايات المتحدة الأمريكية التعدين كسارة الفك

- تستخدم مطحنة الكرة مطحنة

- تستخدم كسارة الحجر للبيع في الصين

- حقوق التعدين في مناجم الذهب التي تباع في ولاية مونتانا

- الكالسيت معجون الأسنان

- الصين ماكينات المحاجر الثقيلة

- Hot Sale Marble Quarry Equipment Best Price Marble Quarry Equipment

- Floor Grinding And Polishing

- Feet Croatia Crushers South Africa For Sale

- Crusher Coal Managing Plant

- Impact Concrete Crusher In Colombia

- Vertical Roller Cement Mill In Cement Industry Worldcrushers

- Surge Crusher Brushless Twin Hull Rc Boat

- Crusher Manufacturers In Rajasthan

- The Flow Chart Of Bauxite Ore Washing In

- Equipment For The Production Of Decorative Stones

- Jamaica Stone Crushers Are Profitable

- Inlay Crushed Stone Supplier

- Regular Wet Grinder Rate In Chennai

- Milling And Micro Grinding Picters

- Crusher Plant 3d Layout Designer Gujarat