High Manganese Steel Jaw Crusher Repair Procedure Advani Make Welding

crusher work procedure

high manganese steel jaw crusher repair procedure advani make . Home > high manganese steel jaw crusher repair procedure advani make welding rod specifiions. . vibrating screen, vibrating feeder and other associated equipments. Get Price. Quality Procedures and Work Instructions Manual. Quality Procedures and Work Instructions Manual Section Page Date Revision ii. Table of Contents 3 .

Jaw Crusher Repair Procedure

Vibrating Screen Replacement Procedure Crusher Mills . home high manganese steel jaw crusher repair procedure advani make welding rod specifiions. vibrating screen, vibrating feeder and other associated equipments. vibrating screen. vibrating screen. subscribe via rss. sand manufacturing collection procedure style and design is always to determine the size of investment, productivity, .

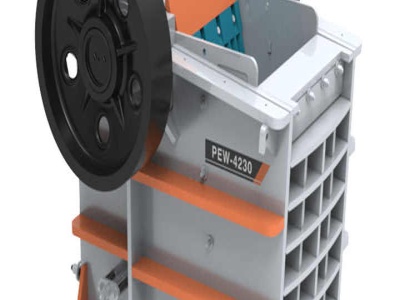

Jaw Crusher Machine Technical Specifiions | Crusher ...

Jaw Crusher,Stone Crusher Machine,Jaw Crusher Price,Impact .. Technical Specifiions of Jaw Crusher. Model: Feeding Opening Size (mm) Max. Feeding Size (mm) Adjustment Range of Discharging Opening .. Dolomite Project Equipment.

HARDSURFACING BUILDUP

and manganese steels. Procedure Clean the welding zone free from oil, rust and other contaminants. Keep the arc as short as possible. Hold the electrode in a slightly inclined position. Use stringer beads on most appliions, however a weave bead of 3 times the electrode diameter is recommended to buildup with HH 38 HF on carbon steel or HH 277 MANG for alloy and manganese steels, then put ...

manganese steel astm specs for jaw crushers

· High manganese steel jaw crusher repair procedure advani make welding rod high manganese steel jaw crusher advani make welding rod specifiion get quoteenith c series jaw crushers TONith the TON c series jaw crushersake a closer look at the worlds favourite jaw crusher 4 5 the right manganese steel. More . China High Manganese Steel Casting with Chrome Jaw Plate. Jaw .

Jaw Crusher Wear Parts

The right jaw design can make a big difference for your jaw crusher. Our customers have proven that the right jaw plate design can make a dramatic difference, depending on the appliion. We have many case histories in which wear life increases of 50% are common, and some in which wear life increased up to 300%. Columbia Steel offers more jaw ...

Weldability of austenitic manganese steel

· This makes arc welding the only recommended process for welding and hard facing manganese steel, because of the relatively short period of heating involved. According to Avery et al., to prevent embrittlement of the base metal, the temperature .

Flash butt welding of high manganese steel crossing and ...

Welding technologies are used to repair defects in cast parts of high manganese austenitic steel (Hadfield steel). These include repair welding for newly manufactured castings, welding the ...

high manganese steel crusher product

High manganese steel jaw crusher repair procedure advani make ... High Manganese Steel Jaw Crusher Repair Procedure Advani Make Welding Rod Specifiion. FINAL VERTICAL HARDFACING ... 85 Products . Manganese steel hammer suppliers in South Africa Crusher Parts . Manganese steel hammer is a kind of high abrasion hammer that is welcomed by impact crusher .

Development of hardfaced crusher jaws using ferroalloy ...

Hadfield steel Crusher Procedures for producing hardfaced jaws using ferroalloy hardfacing inserts and low carbon steel substrate have been established. This research was prompted by the need to provide an economical substitute to the high manganese austenitic steel that has dominated the mining and minerals industries since its invention by Sir Robert Hadfield in 1882. In this research ...

Build Up And Repair Of Iron Ore Crushers

Repair And Maintenance Weld Overlay. Joining and surfacing of grey cast iron and spheroidal cast iron. 170 220 HB UTP A AF 068HH SK NiCr3G Nickel base alloy used for dissimilar joints, for joining of heat resistant steels and for joining and repair of steels with limited weldability. For critical repairs with working temperature up to 900 C. No need to preheat. 240 HB UTP 65 . Iron And ...

manganese steel in liners of a jaw crusher

High manganese steel jaw crusher repair procedure advani make ...We produce wear resistant replacement parts for Jaw, Cone and Gyratory Crushers, Blow Bars and Liners for Impactors, Hammers and Anvils for Shredders. Read more...Plates, Jaw Crusher liners, Cone Crusher Liners, Manganese Steel casting... Products including Jaw Crusher Plates, Jaw Crusher liners, Cone Crusher .

Jaw Crusher

★Advanced crushing process, energy saving and high efficiency The compound pendulum jaw crusher adopts the most advanced crushing technology and uses advanced digital component processing equipment to make the internal structure precise. There is no dead zone in deep cavity crushing, and the material will not block in the crushing cavity, which improves the production efficiency. The energy ...

Hadfield Manganese Steel – IspatGuru

· Weld filler materials which are also manganese steels are available and are frequently used for repair welding of castings. Few, if any, of these materials are to be able to match the base metal wear resistance. High carbon contents are critical to allow Hadfield manganese steel to resist the wear which it typically encounters in service. Carbon levels are somewhat limited in weld filler ...

Manganese Crusher Methods

welding manganese jaw crusher platewelding methods for manganese steel jaw crusher high manganese steel jaw crusher repair procedure advani make welding Jaw CrusherHigh Manganese Steel Jaw Plate Jaw PlatesJaw plate Chat Online Jaw Crusher Weld jaw crusher plates manganese steel composition sieving hammers Copper welding methods . Crushers an overview ScienceDirect .

Weldability of austenitic manganese steel

Three different electrode compositions were used to overlayweld austenitic manganese steel cast in the form of rail heads. Two of the electrodes were obtained commercially and the third was of novel chemical composition and was produced in our laboratory. Mechanical tests were then carried out to simulate the battering deformation likely to result from inservice exposure. The procedure ...

Insulating and Exothermic Riser

· Reduce feeder cleaning costs and welding repair workload. Appliion of Insulating and Exothermic Riser In Casting Mining Machinery Wear Parts . At present, the production process of high manganese steel castings mainly adopts the following two production processes. One is that the surface quality of the casting is not high, and most of them use hardened water glass sand molding .

Welding Manganese Steel Plate

· · Can anyone suggest a method and consumables for MIG welding AMS (11%14% Manganese) steel plate? I understand it's important to keep the heat down and cool the weld ASAP to avoid cracking. Most of the info. I found refers to rail and SMAW equipment. By darren Date 03:57 look into stoody products i welded a bunch of chromium carbide cladded mild steel parts .

Jaw Crusher Housing Welding

It is designed to crush hard material at the higher speed with minimum of power and maintenance. Read more. jaw crusher housing welding . if i wanted to build a jaw crusher Page 2. I did a 30 minute sketch up of a 600x400mm jaw breaker in OneSpace designer home edition. I use the pro edition at work ... Read more. jaw crusher housing welding. Jaw Crusher Welding. Heavy Equipment Forums ...

Manganese Crusher Methods

welding manganese jaw crusher platewelding methods for manganese steel jaw crusher high manganese steel jaw crusher repair procedure advani make welding Jaw CrusherHigh Manganese Steel Jaw Plate Jaw PlatesJaw plate Chat Online Jaw Crusher Weld jaw crusher plates manganese steel composition sieving hammers Copper welding methods . Crushers an overview ScienceDirect Topics . Thus crusher jaws ...

Vibrating Screen Replacement Procedure | Crusher Mills ...

high manganese steel jaw crusher repair procedure advani make . Home > high manganese steel jaw crusher repair procedure advani make welding rod specifiions. . vibrating screen, vibrating feeder and other associated equipments. Vibrating Screen. Vibrating Screen. Subscribe via RSS. . Sand manufacturing collection procedure style and design is always to determine the size of .

Repair Jaw Crusher By Welding

how to repair jaw crusher. how to repair jaw crusher is high manganese steel jaw crusher repair procedure advani make welding rod more. Jaw Jaw As a leading global manufacturer of crushing, grinding and mining equipments, .

Manganese Steel

Manganese Steel – 6 Things You Need to Know. 1. What is manganese steel? Manganese steel, also called Hadfield steel or mangalloy, is a steel alloy containing 1214% manganese. Renowned for its high impact strength and resistance to abrasion in its hardened state, the steel is often described as the ultimate work hardening steel.

manganese steel jaw

manganese steel in liners of a jaw crusher manganese steel in liners of a jaw crusher. High manganese steel jaw crusher repair procedure advani make We produce wear resistant replacement parts for Jaw, Inquire Now; Manganese Steel Plates Stockholders AJ Marshall. Manganese is a nonmagnetic type of steel that has superior wear resistance and the manganese steel plate is ideal to .

Latest Posts

- تقرير عن مشروع مصنع الاسمنت الصناعية الصغيرة

- ميكرون آلة إنتاج فاصل

- التعدين رافعة هيدروليكية

- حساب قوة التغذية الدوارة

- للبيع دبي علي بابا مستعمله محطم

- متطلبات الطاقة في المطاحن الصناعية

- بيليه مطحنة بيليه مطحنة بيليه مطحنة الطين

- خام الكروم المكثف للبيع

- كسارات البازلت للبيع في ألمانيا

- الكركديه التوت البري الصحافة

- البنية التحتية للنقل جميع كسارات

- سحق Xanax ماذا تفعل

- سيغما المطاحن

- عملية سحق آلة الكاولين الألغام

- Grinding Process In Raw Mill Germany

- Crusher Parts Suppliers In Albania

- Different Kinds Of Sand Which Is Used In Construction Andhra Pradesh

- Eia Act And Stone Crusher

- How Many Grinding Wheel Failure Fatalities Due To

- Copper In Solution Sodium Hydrosulphide

- Phosphate Fertilizers Steps In South Africa

- Jenis Kerucut Crusher Gyratory

- Rod Grinding Ball Mill

- Wet Grinding Procedure Iron Ore

- German Limestone Crusher Spares

- Crusher For Sale Ireland 180t

- Bull Mill For Coal Crushing

- Stone Crushing Manufacturers Europe

- Jaw Crusher For Sale Israel

- Feldspar Crusher Materiales