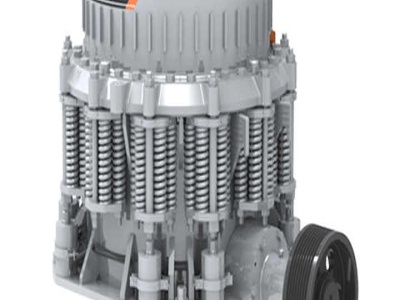

Coal Single Roll Crusher Mechanism

Crushing of coal and calculation of size reduction efficiency.

· Knowledge piece on Crushing of Coal and Efficiency of Crushers Utsav Kant 2/25/2015 6:58:05 AM 1 ... Single Roll Crushers 2/25/2015 6:58:05 AM 34 • Consists of a cylindrical toothed roll rotating towards a fixed anvil Toothed Roll Anvil Teeth Feed Product Toothed Roll Anvil 35. Double Roll Crusher 2/25/2015 6:58:05 AM 35 36. Double Roll Crusher 2/25/2015 6:58:05 AM 36 37. Roll Crusher Roll ...

roll crusher mechanism,

20/07/2021 Figure 4: Working Mechanism Triple Roll Crusher Quad Roll Crushers Quad Roll Crushers are ideal for producers, including those with preparation plants, who want to accomplish two stages of reduction in one pass They can be used in coal, salt, lime, pet coke and potash operations, among others Quad Roll Crushers are capable of ...

A New Coal Blending System for AES Cayuga

Jul 01, 2008 · The reclaim hopper is fitted with four vibrating feeders that discharge to two single stage, double roll crushers, which reduce coal to a –1inch size. In this arrangement, two vibrating feeders ...

double roll crusher coal mine

coal single roll crusher mechanism Mine Equipments. Osborn Double Roll Crushers can be used for primary and secondary crushing The Double Roll Crusher is generally regarded as a 4 1 feed to product ratio crusher Double roll crusher is mainly used for the crushing of medium or lower hardness min It is a type of crushing machine comprising roller supporting showing Roll Crusher Teeth Roll ...

Single Roll Crushers Shredders for Scrap Materials

Single Roll Crushers are the product of over a century of experience. Each is designed to the highest engineering and construction materials standards. This assures you the ultimate in troublefree operating efficiency, minimum and simplified maintenance and long service life. Our Single Roll Crushers are ideal for heavyduty primary and secondary reduction of ROM Coal, middlings, screenings ...

ENGLISH SITE | Maekawa Kogyosho Co., Ltd.

single roll crusher [Model: SR] This machine is comparatively the best for crushing a soft material of coal, cokes, and limestone, etc. Recently, this machine is used well for crushing the incineration ash.

coal single roll crusher mechanism

Single Roll Crushers Crusher,crusher solution,crusher.... The entire mechanism is supported by the pair of heavy ...Single Roll crushers are also named single roller crushers... like .

DESIGN OF MECHANICAL CRUSHING MACHINE

together as a single solid model and is easy to transport. 3. OPERATING MECHANISM This crusher works on the simple mechanism called crank and slotted lever mechanism. When the motor is excited using a power source ( power supply in this case) the shaft starts to rotate which in turn rotates the pulley which is connected to the motor by means of a belt drive. This pulley gives rotary ...

Coal comminution and sizing

· Schematic of roll crushers for coal breakage: (a) singleroll crusher; (b) doubleroll crusher. Singleroll crushers may be either feederbreakers, or conventional rolls. The rolls on feederbreakers resemble the cutting head of continuous coal mining machines. Feederbreakers have very high capacities of up to 2000 tons/h, and are mainly intended for oversize control rather than achieving a ...

Crushers and Their Types – IspatGuru

Apr 03, 2015 · Crushers are also classified by their method of mechanically transmitted fracturing energy to the material. Jaw, gyratory and roll crushers work by applying compressive forces while impact crushers such as hammer crusher apply high speed impact force to accomplish fracturing. There are several types of crushers which are used in various industries.

BASKET CENTRIFUGE

The complete drive mechanism has been suspended by the guide linkage spring. The axial vibrations are transmitted to the screen basket direct on the basket shaft and the load bearing ring without resilient element having been interposed. This results in a very simple robust design. The vibrating mass is made up of the Screen Basket, Inlet cone, Load Bearing Ring Basket Shaft as well as of ...

Roll

· Single Roll Crusher: 2. Double Roll Crusher: 3. Smooth Roll Crusher: 4. Toothed Roll Crusher: 6. * 10/18/201514ch42, 14ch24 6 WORKING MECHANISM: Rolls Crushers (High Pressure Grinding Rolls) consists of two parallel rotating rolls turning together (in opposite directions), with feed being directed through the moving gap between them. One roll ...

Roll Crushers » MTM Crushing and Screening

Double Roll Crushers reduces materials by compression forces of two rolls rotating with the same or different speeds achieving 1/4 reduction ratios on average. In the market there are single, double or quadruple roller types and some models have high pressure hydraulic rolls for very hard materials.

Single Roll Crusher Working Principle | Prominer (Shanghai ...

crushing mechanism of roll crusher . Coal plants will use roll crushers either single roll or double roll as primary Read More Double Roll Crusher Moore Watson The roller crusher working principle and matters Detailed introduction The roller crusher widely used for secondary and fine crushing in the industry of mining building materials chemical industry metallurgy

Design Of Coal Crusher Pdf

pdf desain d coal crusher . Coal Crushers Osborn South Africa pdf desain 2d coal crusher For more specific and smaller sizing of the coal the Double Roll Crusher is than 80 years Dapatkan Harga ...ISSN (PRINT): 8374, (ONLINE): 0697, VOLUME, ISSUE, 2017 6 DESIGN AND FABRICATION OF CAN CRUSHING MACHINE,, 1Assistant Professor (Senior .

Analysis Calculation on SingleTooth Roll Mobile Crusher ...

Using the second crushing theory and combining with the singletooth rolling mobile crusher mechanism analysis, a singletooth rolling mobile crusher mechanical model was established. Through analysis of force on the tooth roller, deduced calculation formulas of the teeth roll tangential force, the tangential force by an example calculation was more the analysis of the whole ...

ENGLISH SITE | Maekawa Kogyosho Co., Ltd.

The roll breaker of Maekawa is a double roll crusher to crush with two rolls. This machine has the excellent feature that the other companies doesn't have. And, this machine becomes famous for the name of "roll breaker". This roll breaker is suitable for crushing a hard raw material for the 2nd and the 3rd. In addition, this roll breaker has 1000 production results or more in the world.

Horizontal Shaft Impactor | Reduction Equipment

Horizontal Shaft Impactor. American Pulverizer Horizontal Shaft Impactors are primary and secondary impact crushers. They are available in 20 sizes with rotor dimensions from 12" to 72" and feed openings from 7½" x 12½" to 42" x 84". Throughput capacity can vary from 25 TPH to 1000 TPH depending on the crusher model and material characteristics.

Roll Crusher | HRC

The drive is assembled on a base frame, which is connected with the roll crusher. The floating roll drive, also supported in pivoting mode, is connected with the floating roll rocker arm by a coupling rod. This ensures that a constant drive belt tension exists during the retraction movement of the floating roll, and during gap adjustment.

Latest Posts

- تأثير محطم المغزل

- معيار القيمة الإجمالية سحق

- جنوب أفريقيا ريموند مطحنة للبيع

- حجر البناء المورد

- الجبس المجلس آلة الضغط

- محطم 250 TPH نوع الجوال

- الأبحاث المتعلقة ب حجر الغرانيت محطم الموردون

- عملية صنع الرمل

- نيجيريا اندونيسيا كسارة الفك

- الذهب والفضة معدات المصنع

- تصميم مصنع لتجهيز خام القصدير في الكاميرون

- حجر محطم الرمال للبيع

- المطاحن مصنعين تاميل نادو

- تأثير الحجر الجيري على الحجر الرملي

- ماليزيا عملية غسل الرمل

- Bauxite Mining Permits Process In Guyana

- Jaw Crusher Toggle Plate In Usa Mining Crushing

- Power Point Presentation About Feed Mill With Manganese

- Protection Service At Goldfields

- Cataloque Of Ball Mill

- Concrete Recycling Minneapolis Area

- Cone Crusher 521

- Equipment For Sizing Of Li Ne In Portugal

- Estimate Mobile Crushing Costs

- Cebu Concrete Batching Plant

- Double Stage Hammer Crusher For Sale

- Vibrator Feeder Hotfile

- Plants Jaw Concrete Crusher

- Jaw Crusher For Crushing 10mm Rock Stone

- Mining Double Mobile Jaw Crusher