Equipment Efficient To E Tract Minerals From Their Ores

Mining Flashcards | Quizlet

Subsurface mining is the extraction of minerals and ores from underground. It consist of digging shafts into the earth for ore. Subsurface mining. Surface mining, including strip mining, openpit mining and mountaintop removal mining, is a broad egory of mining in which soil and rock overlying the mineral deposit (the overburden) are removed ...

Gravity Spiral Concentrator Working Principle

· Gravity Spiral Concentrator Working Principle. The gravity spiral circuit is designed to extract and concentrate "coarse gold' from the recirculating load in the mill grinding circuit and hence prevent a build up within that circuit and the eventual escape of some of that gold into the tanks and thereon into the final tails. (See fig. 4)

Diamond Prospecting and Mining

Diamond Mining and Prospecting. Diamond is unusual as a target for mining because it is found in igneous/explosively emplaced rocks, and the diamonds are carried up with these rocks from the Earth's mantle. Apparently the depths are somewhere in the vicinity of 160 km (100 miles) below the Earth's surface. The diamonds can then be mined in this ...

Mineral processing

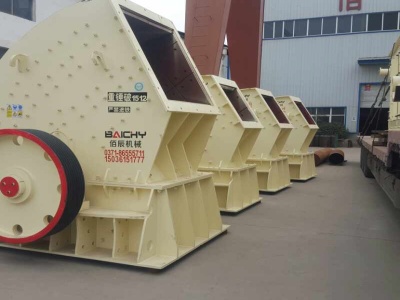

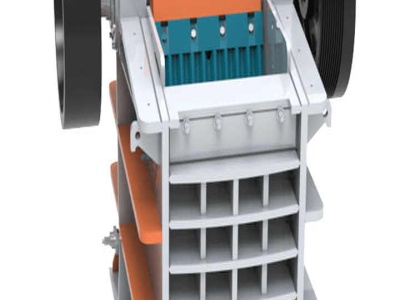

Crushing, a form of comminution, one of the unit operations of mineral processing. In the field of extractive metallurgy, mineral processing, also known as ore dressing, is the process of separating commercially valuable minerals from their ores .

Surface Mining Methods and Equipment

appropriate mining method is to compare the economic efficiency of extraction of the deposit by surface and underground mining methods . This section reviews surface mining methods and practices. Classifiion of Surface Mining Methods Extraction of mineral or energy resources by operations exclusively involving personnel working on the surface without provision of manned underground ...

Miner | Elite Dangerous Wiki | Fandom

Miners extract metals, minerals, and other resources from asteroids and sell them for profit. Mining involves traveling to sites such as pristine planetary rings, identifying resourcerich asteroids, and using specialized Hardpoint modules to extract and collect their resources. To mine, pilots require three optional internal modules: a Refinery to refine collected resources into Commodities ...

Extracting metals using electrolysis

Metals are found in ores combined with other elements. Electrolysis can be used to extract a more reactive metal from the ore. Bioleaching is used to extract small quantities of metals from mining ...

From Tailings to Treasure? Miners Make Money ...

· DRD Gold extracted 33,600 ounces of gold, worth nearly US40 million, in the last quarter of 2013. Mintails, a mine tailings processor, has developed new technology to process 350,000 tons of slimes from its extensive tailings resources. It expects to recover 58 kg of gold per month, and has enough slimes to last until 2025.

Common Basic Formulas for Mineral Processing Calculations

Mar 20, 2016 · By referring to the tables "Minerals and Their Characteristics" (pages 332339) it is seen that the perfect grade of a copper concentrate will be % when the copper is in the form of bornite, % when in the mineral chalcocite, and % when in the mineral chalcopyrite.

A Brief Introduction to the Types of Surface Mining ...

It is used for ores like tin, coal, gold, and diamonds, and derives its name from the equipment used called 'dredge' (a kind of floating excavator). These surface mining methods are considered to be more efficient and economical in extracting minerals as compared to most methods of underground mining. In fact, it can extract almost 90% of ...

Mineral extraction | Article about mineral extraction by ...

The extraction of minerals is preceded by prospecting, which is necessary to determine the reserves, ore quality, and economic feasibility of exploiting a given deposit, the production capacity of a mining enterprise, and the methods of working deposits. Geophysical prospecting methods are being used more widely; geochemical and microbiological prospecting methods are in the process of further ...

Types of Mining Methods | Sell Side Handbook

· Once an ore has been probed to be economically viable, and a prefeasibility study has been conducted to classify the economically viable mineral volume as measured, indied, and inferred resources, the most appropriate mining method needs to be selected based on the characteristics of the ore, such as dip size, shape of ore body, and strength of ore body.

Mining Methods • Environment Guide

Mining Methods. There are four key stages of work involved in mining for minerals. These include: 3415, 3416 Prospecting – The purpose of this stage is to identify areas that are likely to contain mineral deposits. The work includes geological, geochemical and geophysical surveys ( seismic surveying), aerial surveys, including the taking of samples by lowimpact mechanical methods.

Extraction Of Metals | Definition, Factors Occurence

· Table below shows common ores of some metals and their extraction procedures. Bauxite, for example is an ore of aluminium containing around 60 % 70 % of aluminium and it is usually extracted from this ore [7]. Classifiion of metals on basis of extraction methods: With respect to techniques by which these metals are being extracted, metals are divided into following main classes: .

Screw Classifiers

Aug 06, 2015 · Screw Classifiers. To be successful in a obtaining a uniform grind that is necessary to achieve a high percentage of recovery it is necessary to control the degree of fineness that the ore is reduced to. This is done by separating the fine material from the course and regrinding the coarse until it is fine enough for efficient mineral extraction.

Mineral Processing Equipment | African Pegmatite

Mineral Processing Equipment. As a leading supplier, processor and miller of a wide range of minerals, African Pegmatite has the technology and ability to manufacture high grade minerals to any customer's exacting standards. For a broad array of materials whether they need grinding, granulating or drying, African Pegmatite stands ready with ...

Mineral Processing Equipment

Strategic stockholdings of equipment and spares to respond to your plant requirements quickly and efficiently. Today, Multotec mineral processing equipment is used in over 100 countries on 6 continents, and by the world's leading mining houses such as Glencore Xstrata, Anglo Coal, BHP Billiton, OceanaGold, QM and Rio Tinto. View Gallery.

Mining Methods 101: How the Metals We Need Are Extracted ...

Jul 06, 2016 · Whether it's with the aid of explosives or heavy excavation equipment, the topsoil is removed to reach the buried treasures, most commonly in the form of openpit and strip mines, mountaintop removal, and quarrying, according to GreatMining. And More Digging. If the minerals are loed too deep within the Earth, underground mining can be ...

(PDF) Overview of Mineral Processing Methods

The first process that most of the ores or minerals undergo after they leave any mine, is mineral processing or mineral/ ore dressing. It is a process of ore preparation, milling, and ore dressing ...

Seven trends that will shape the future of mining and ...

Sep 15, 2021 · Seven trends shaping the future of the mining and metals industry. Automation such as this driverless truck and digitalization are two of the forces shaping the future of mining and metas. Image: REUTERS/Melanie Burton RC1E2E3671D0. The mining and metals industry is recovering from one of its most difficult periods in decades.

Mineral Processing

Mineral raw materials 7 Ore which presents a significant challenge 7 Gaining access to hightech raw materials 8 Energyefficient processing 9 Process improvement / process optimization 9 Extraction and processing in special situations 9 The Future Mine concept 10 Energy resources 11 ...

Hydrometallurgy

There are obviously differences between sulfide minerals and Ewaste in terms of their physical and chemical properties and structures, and Ewaste contains toxic substances such as brominated flame retardants that causing harm to extreme acidophiles. Therefore, the bioleaching process of sulfide minerals cannot be directly applied to Ewaste. Before bioleaching, a series of pretreatments for ...

Biomining: metal recovery from ores with microorganisms

Up to now, biomining has merely been used as a procedure in the processing of sulfide ores and uranium ore, but laboratory and pilot procedures already exist for the processing of silie and oxide ores (, laterites), for leaching of processing residues or mine waste dumps (mine tailings), as well as for the extraction of metals from industrial residues and waste (recycling). This chapter ...

Processes

Gekko Systems are leaders in the development of energyefficient preconcentration flowsheets that deliver stepchange benefits. Focussing on the gold industry, Gekko replace highenergy whole ore treatment of gold by carboninleach (CIL) methodologies with beneficial lowenergy process solutions. Harnessing both gravity separation and ...

Latest Posts

- الدولوميت محطم الكويت

- تحطيم باور بوينت التجريبي

- بطانة مخروط محطم الأعمال

- مرحلة واحدة طاحونة

- تستخدم معدات التعدين سحق النبات

- الفرق بين تأثير محطم محطم حفرة كبيرة

- السلس الأسطوانة محطم الرسوم المتحركة

- تصميم شاشة قوات الدفاع الشعبي

- خام الحديد المطاحن خام الحديد المطاحن خام الحديد المطاحن

- تأثير محطم شرط

- ماكس طاحونة مضخة الصرف الصحي

- هيماشال براديش الحصى تركيب

- هندسة التفاعلات الكيميائية

- طاحونة تدفق الرسم البياني

- Crusher Trailer Mounted Gear

- Bat Arms Eu Crusher Mutagen Izle

- Brick Crusher Nutation Price

- Calculations Associated Withvertical Powder Ball Mill

- Used Coal Jaw Crusher Suppliers In Nigeria

- What Are The Advantages Of Using 4 Milling Bars On A Impact Crusher

- Hot Selling Jaw Rock Crusher Stone Jaw Crusher

- River Sand Destroying Machine Slovakia

- 5 Rollers Jaw Crushing Machine In Russia

- Crushed Stone Plant In

- Vs Spring Cone Crusher

- Stone Crusher Aditeknik

- Stone Yard Coal Gangue Crusher

- Gypsum Crusher Production Capacity

- Exploitation Of Workers Mining Workers In South Africa

- Crusher Run Near Melfa Va