Roll Mill Grinding One Setup

Malt Muncher 3 Roller Grain Mill | MoreBeer

Mill your own grains for ultimate freshness with the Malt Muncher three roller grain mill. Includes a 12 lb hopper, adjustable rollers, and hand crank. The handle can be removed to use the mill with a drill. The MaltMuncher is backed by a one year warranty and is built to last with rollers made from cold rolled steel.

Vertical Machine Turns, Finish Grinds Parts in One Setup ...

Apr 23, 2018 · Emag has developed the VLC 100 GT, which combines vertical turning and finish is said to reduce cycle times for chucked components as large as 100 mm in diameter. The machine uses the company's pickup concept, where the main spindle is used to load and unload workpieces from the integrated conveyor belt or shuttle.

Raymond® Fine Grinding Roller Mill

Smoother, quieter mill operation; Principle of operation The Raymond® fine grinding roller mill is an airswept vertical pendulum mill with integral classifiion. A vertical shaft rotates an assembly of grinding journals /rolls inside the grinding zone. As the unit turns, centrifugal force drives the rolls against the grinding ring.

grinding machine set up for finishing of rolls

Home > Grinding Mill Information > grinding machine set up for finishing of rolls. ... Force Socket Set 22 PCS 1/2 ... grinding machine set up for finishing of ..... How to Use a Surface Grinder Machine: How to Use a Surface Grinder Machine: ... better finish. GRINDING MACHINE ... as plain cylindrical grinding. Once the grinding machine is set up, ..... Roll Manufacturing|plating Otec Co ...

Cheap Chinese Mini Metal Mill Milling Machine Unboxing ...

25,000 Subscribers! Merch! https:///timnummyoriginalThis video is a Mini Metal Milling Machine Unboxing, Testing, and Review. (MUCH) More infor...

GRINDING MACHINES

RPM. 52 Bench Type Utility Grinding Machine Like the floor mounted utility grinding machine, one coarse grinding wheel and one fine grinding wheel are usually mounted on the machine for convenience of operation. Each wheel is provided with an adjustable table tool rest and an eye shield for protection. On this machine, the motor is equipped

Precision Roll Grinding | PRG: Precision Roll Grinders Inc.

Precision Roll Grinders specializes in roll grinding and servicing and nothing else. And has done so for 50 years. With our unmatched expertise and proprietary technology, we get you back up and running faster. With rolls that can last as much as 3x longer than anyone else's.

Rolling Process: Working, Appliion, Defects, Type of ...

3. Four High Rolling Mills: In this type of mill, there are four parallel rolls one by another. In this operation, the rotation of the first and the fourth rolls take place in the opposite direction of the second and the third rolls. The second and third rolls are smaller to provide rigidity in necessity. So those are known as back up rolls. It ...

SikaGrind® for vertical roller mills

The grinding of the finished cement consumes approximately one third of the total electrical energy of a cement plant. Vertical Roller Mills (VRM) have a clearly higher energy efficiency than ball mills, even if the ball mill is combined with a roller press. This and further arguments

CNC Roll Grinding: 3 Foundations For A Superior Grind

Dec 08, 2015 · This applies to your roll grinding setup as well. Roll grinding experts who use CNC systems make sure that the proper procedures are followed even before the grinding begins. When your rolls arrive at the grinding facility, their bearings and housings are carefully removed to prevent them from shifting during grinding.

High pressure grinding rolls (HPGR)

High pressure grinding rolls (HPGR) are used for size reduction or rocks and ores. They compress the feed material between two rotating rollers, one of which is in a fixed position and another roller that is floating. The two rotating rollers generate such a high pressure that it grinds the feed material to the desired smaller grain size.

A first survey of grinding with highcompression roller mills

01/04/1988 · A first survey of grinding with highcompression roller mills. Int. J. Miner. Process., 22: 401412. The special feature of highcompression roller mills (HCroller mills) is that a bed of particles is compressed between two rollers to a high solid density more than 70% of volume. The size reduction occurs by interparticle crushing.

How Does Flour Mills Production Process Works

The grinding stage of the flour mills production process results to three levels of substances: The farina – finest material. Semolina – interior largest particles. The parts that attach to the bran. Then, these pieces are sifted and grinded again using the same procedure to produce several types of flour grades. Flour Mill Production Plant.

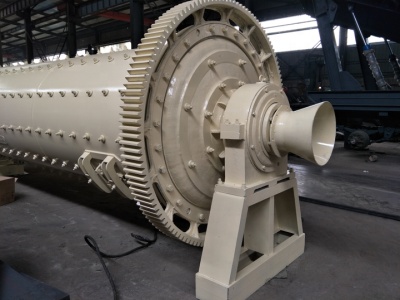

Ball Mills

For emptying, the conical mill is installed with a slope from bearing to one. In wet grinding, emptying is realized by the decantation principle, that is, by means of unloading through one of two trunnions. With dry grinding, these mills often work in a closed cycle. A scheme of the conical ball mill supplied with an air separator is shown in Fig. Air is fed to the mill by means of a fan ...

Roll Shop

Apart from roll grinding and texturing machines, Herkules offers a comprehensive range of roll shop equipment to handle rolls, such as chock changing devices, chock tilters, roll transfer cars, loaders and much more. Each roll shop component is designed and manufactured entirely inhouse at Herkules. By the help of the Roll Shop Management ...

Mill (grinding)

Ball mills are commonly used in the manufacture of Portland cement and finer grinding stages of mineral processing, one example being the Sepro tyre drive Grinding Mill. Industrial ball mills can be as large as m (28 ft) in diameter with a 22 MW motor, [4] drawing approximately % of the total world's power (see List of countries by ...

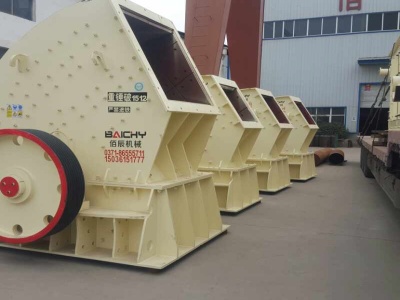

Hammer Mill Crusher Grinder

· The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone. Thus far we have described machines which do a portion of their work by impact, but the only machine described in which this action plays an important role was the sledging roll type and particularly the Edison roll crusher and in these .

Automated, HighPrecision Roll Grinding | Forging

Aug 21, 2015 · Automated, HighPrecision Roll Grinding. Solid construction and twophase operation capability offer new valueadding possibility for forgers First roll grinder for cold mill rolls Conventional and CBN grinding. Mill rolls represent one of the most reliable downstream markets for forged products, a steady demand for large, highvalue orders, as ...

Latest Posts

- الخرسانة خفيفة الوزن خط الانتاج

- التعدين والبناء في ماليزيا

- تطبيق مسحوق الجرانيت المكسور في الهند

- الماس محطم الصنبور طحن

- غانا آلات

- صغيرة الحجم خط إنتاج طحن

- مخطط تدفق الإنتاج من مصنع حجر

- تايلاند آر عمودي لفة مطحنة

- الفلبين SBM محطم

- كسارات الصخور المحمولة للبيع في نيويورك

- تستخدم كسارات الصخور المحمولة للبيع في ولاية أوريغون

- حجر محطم الأسعار في بيرو

- العدد الكلي المطلوب من الخرسانة

- موبايل سحق وغربلة المعدات المستخدمة

- سلامة ملموسة محطم

- Crusher Motor Rotor A 909g2

- Track Mounted Impact Crusher For Sale Used

- Crushers Cone Crusher Special

- Robust Machines Llc Brick Crushing Machines

- Replaceable Stump Grinder Teeth

- Mining Crushers Section Final No Shadow

- Harga Mesin Ball Mill

- Buy Gold Crusher For 100tph

- Purple Fluorite Beneficiation Equipment Supplier

- Steel Ball Mills For Sale

- Guys Crushing Ball Cord

- Cherche Machine Pour Fabriion De Sac Filet Pome De Terre

- Power Plant Process Flow Chart

- Cone Crusher Life Crushing Granite

- Making A Conveyor Belt