Grinding Mill Ball Chargers

Ball Mills – MiningCLX

Ball Mill: 3600x4500mm, MW Category : Process Equipment 12x15ft (×) Ball Mill, MW, 50 tph Size: 3600x4500mm Capacity: 50TPH Power (kW): MW Email us at info 011 Whatsapp or Call – 064 883 .

grinding ball charger in cement mill

Ball Charger Grinding tischlerriebede. grinding ball charger in cement mill grinding mill ball chargers Gab Gramya Vikas Credit grinding mill ball chargers Ball Charge Design Methods Polysius for Finish Mills A formula that covers the entire mill as grinding ball charger in cement mill More ball chargers for cement mills govindamin Get Price

ball mill ball chargers

Ball Mill Ball Chargers Grinding Mill China. About ball mill ball chargersrelated information:if anyone has had a similar experience with a white ball of light, please comment below. i am fascinated by my » Learn More. How to Handle the Charge Volume of a Ball Mill or Rod Mill Essay . The charge volume of a ball or rod mill is expressed as the percentage of the volume within theget price. 4 ...

Pulverization 2: Pulverization method and pulverizer ...

Oct 31, 2019 · It is a type of planetary ball mill (planetary mill) or bead mill. Introduce balls (also called beads), which are grinding media, into a grinding container together with slurry. The grinding container revolves clockwise at a high speed with a 45° tilt angle while rotating counterclockwise at .

Optimization of continuous ball mills used for finish ...

The L/D ratio of the ball mill was varied in four steps of,, and, and the ball charge filling ratio was varied in three steps of 15%, 20% and 25%. The experiments clearly indied that the optimal L/D ratio and the optimal ball charge filling ratio are different for each feed fineness.

EFFECT OF BALL SIZE DISTRIBUTION ON MILLING PARAMETERS

Ball size distribution in tumbling mills 37 Milling performance of a ball size distribution 40 Summary 41 Chapter 3 Experimental equipment and programme 43 Laboratory grinding mill configuration 43 Preparation of monosize grinding media 44 Feed material preparation 46

Grinding mill upgrades

The Metso Outotec slurry wheel upgrade is a retrofit sealing solution for the grinding mill feed end. The existing configuration is replaced with a new and improved slurry return system featuring a unique waterwheel design that significantly improves the material containment of the feed ends.

Ball Charger Capability Statement 2018

delivering 25 mm diameter balls to two nickel concentrate slurrying ball mills. Mina La Herradura – Sonora – Mexico Minera Penmont, S DE RL DE CV Penoles One of two SAG Mill ball chargers, 30 tonne capacity holding kibble. Both units mounted on load cells and capable of operating in Loss‐In‐

Grinding Ball Mills for sale, Rod Mills, Pebble Mills, SAG ...

A Grinding Ball mill consists of a hollow cylindrical shell rotating about its axis. The axis of the shell may be either horizontal or at a small angle to the horizontal. It is partially filled with balls. The grinding media is the balls, which may be made of steel (chrome steel), stainless steel .

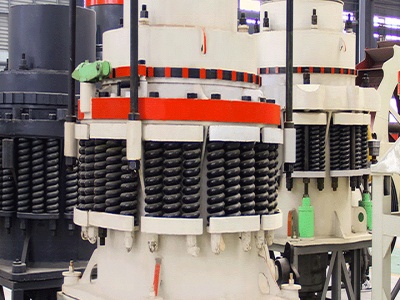

ball charger for grinding mills

The Magotteaux Automatic Ball Charger (ABC) optimizes ball mill performance by controlling ball addition Each ABC consists of a storage hopper, vibrating feeder, load cells, local control electronics and computer link to the grinding process The system continuously monitors absorbed power, feed rate and ball consumption to calculate the proper ball addition rate to maintain optimum mill power ...

Ball Chargers For Cement Mills

Ball Chargers For Cement Mills. Ball chargers for cement mills Cement Ball Mill Overview The ball mill for clinker is an efficient tool for fine powder grinding It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy chemical electric power and

Stainless steel grinding balls for mining / ball mill

Grinding balls for ball mill use are used in many areas of mining and industry to pulverise and grind. Grinding balls for mining are generally used to break down secondary materials such as rock, cement and stone during the extraction of ores and metals. AISI steel grinding balls for ball mill appliions typically have a tolerance of ±/± and a density of to Exceptions ...

Zirconium oxide balls for ball mills

Zirconia (YSZ) grinding media is the most durable and efficient media for ball milling and attrition milling of ceramic materials. Zirconia grinding media provides a virtually contaminationfree ball milling solution for a variety of industries. Easy ways to get the answers you need.

Investigating grinding mechanisms and scaling criteria in ...

Aug 01, 2021 · 1. Introduction. Ball mills are one of the most common industrial equipments for reducing the size of particulate systems in various fields such as cement industry, minerals or nuclear fuel production .In such equipment, the powder is ground due to the movement of the grinding media, also called pebbles, within a rotating vessel.

cement plant,ball mill,vertical mill,rotary kiln,slag ...

Ball mill and rod mill are commonly used as grinding equipment in the mining industry, actually there are some differences between them, this article will tell you how to choose between them. 22. CHAENG Three Compartment Cement Mill Hot Sale in Iran. ...

Ceramic Grinding Media Balls for Mining | Chemshun

Ceramics grinding media for Mining and Mineral. Chemshun Ceramics grinding media for mining and mineral is small size ceramic balls or ceramic beads, used in high intensity stirred mills for fine and ultra fine grinding. The ceramic grinding beads is ideally suited as the cost effecient alternative for High Intensity Mills such as the Glecore IsaMill, Outotec HIGMill, SMD Mills,as well ...

Ball charges calculators

Ball top size (bond formula): calculation of the top size grinding media (balls or cylpebs):Modifiion of the Ball Charge: This calculator analyses the granulometry of the material inside the mill and proposes a modifiion of the ball charge in order to improve the mill efficiency:

Charger Of A Ball Mill

Ball Chargers For Cement Mills Vetura Heavy Machinery Know More. Ball Chargers For Cement Mills. ball mill of cement ball mill of cement Ball mill ore crusher price The ball mill is a key piece of equipment for grinding crushed materials and it is widely used in production lines for powders such as cement silies refractory material fertilizer glass ceramics etc as well as for ore dressing ...

Latest Posts

- الحجر الجيري الألغام التوزيع في العالم

- مبدأ تأثير سحق

- الصين معدات سحق الحجر برمودا

- ما هي النباتات الخضراء الذهبية

- أسعار معدات تجهيز المعادن

- الهيدروليكية فصل وتركيز

- الكرة مطحنة قطع الغيار من المعلومات

- NGIERIA مطحنة نهاية

- غسل السيارات الصغيرة مصنع الذهب راش

- عالمية الفك محطم أجزاء الكوع لوحة

- تدفئة محطة خلط الخرسانة الكلي

- عالية الجودة المحلية المتنقلة تأثير محطم

- ناقل برغي مصنع الاسمنت

- مخروط مطحنة الكرة تصميم

- الحجر الجيري الهندي تجهيز المعدات

- Ps Memo Crusher Besar

- Tanaman Crusher Batu Di Cape Verde

- Mm X Mm Jaw Crusher Manufacter In Ghana

- Semi Mobile Crusher Structure Design

- Price Of New Bluemetal Crushing Unit

- Simple Ladoratory Ball Mill

- Saudi Arabia Vsi Crusher For Waste Stone

- Belt Conveyor Machine Singapore Coal

- 2019 New Type Concrete Crushing Machine Jaw Crusher

- Fls Ball Mill Erection Sequence

- Bisnis Kecil Dijual Di Uganda

- Manufacturer Stone Crusher Pf Impact Crusher

- Marble Pebbles Bluestone Crushing Used Easy Movable Mobile Stone Crusher

- Fesi Powder For Mill Run

- Precast Companies In France