Surface Grinding Common

Types of Surface Grinding Techniques

Jul 26, 2021 · The surfacegrinding process involves smoothing out the surface of a metallic or nonmetallic material with various grinding machines and tools. Surface grinding can help refine the surface of a piece as a part of the finishing process, or it can help a material attain a more workable surface for better functionality. This process is commonly ...

Optimization of Process Parameters in Surface Grinding ...

Surface grinding is the most common process used in the manufacturing sector to produce smooth finish on flat surfaces. Surface quality and metal removal rate are the two important performance ...

What is Creep Feed Profile Grinding and how does it work?

Since many profile grinding tasks in series production are performed in creep feed grinding, grinding of turbine blades, CD grinding (continuous dressing) is the most economical solution. The wear of the grinding wheels is immense, but due to the always sharp abrasive grain, higher infeeds and feed rates can be selected.

Grinding Cups | McMasterCarr

A large grinding surface, combined with a thick layer of rough abrasive removes more material than other wheels. They are also known as Type 11 wheels, flaredcup wheels, snagging wheels, and cup stones. Wheels are often used to grind weld seams and remove flaws from castings. The full backing provides additional support.

Surface Grinding Vitrified Wheels | Vitrified Wheels | CGW ...

Surface Grinding Vitrified Wheels. • Surface grinding is the most common of the grinding operations. Surface grinding wheels can be used for heavy stock removal to a very precise finish and size requirements. Matching the right wheel with the appliion is very important to achieve the needs of the grinder. • Surface grinding is done on ...

Surface Grinder Flashcards | Quizlet

The importance of horizontal spindle surface grinding is increasing for what primary reason? Tolerances of 50 millionths of an inch are common place today. Why is avoiding metallurgical damage during grinding often of critical importance? The safety of vehicles that use highly stressed parts is at stake.

Machining surface finish chart, conversion, comparator ...

Machining surface finish chart, comparator, method, degree, Ra, Rz, RMS. As for machining to iron and steel castings, the surface finish smooth degree is also an important requirement. The following is the conversion chart is from dandong foundry, for Ra (um), Ra (micro inch), Rz (um), RMS and finish degree in China and USA, including the ...

Surface Roughness Produced by Common Production Methods ...

The chart below provides surface roughness values produced by common processing methods and is intended to be used as a general guideline. The ability of a processing operation to produce a specific surface roughness depends on many factors. ... For example, in surface grinding, the final surface depends on the peripheral speed of the wheel ...

Surface Grinding Wheels | GMSi Group

Surface Grinding Wheels We have available many options based on decades of experience in production surface grinding appliions. All common sizes and shapes are readily available or we can work with you to custom engineer a wheel for your appliions. Please contact us with your required results. We will need to know the following: Current abrasive grade and specifiion Shape and ...

![14 Types of Grinding Machines [Working, Diagram PDF]](/i7ud2wy/1128.jpg)

![14 Types of Grinding Machines [Working, Diagram PDF]](/i7ud2wy/1257.jpg)

14 Types of Grinding Machines [Working, Diagram PDF]

May 25, 2021 · The cylindrical surface is grinded with a machine in which grinding wheel is fitted on the shaft of a free electric motor. In this type of grinders, the grinding wheel is fitted on the machine's work table, which can be given crossfeed and the entire surface of the job can be grinded.

What Is A Surface Grinder

The surface grinding machine is the most common type of grinding machine found in any shop. You can actually compare it to milling cutter that has multiple teeth but the surface grinding machine has a grinding wheel, which makes it an abrasive cutting tool. The wheel is used to remove really small pieces of metal (known as swarf).

SURFACE GRINDING | R S Grinding

Surface grinding is the most common of the grinding operations. A rotating wheel is used in the grinding of flat surfaces. However, the grinding wheel is not limited to just a cylindrical shape, but can have a myriad of options that are useful in transferring different designs to the object being worked on.

7 Types of Grinding Wheels on the Market Today | Action ...

Sep 11, 2019 · 4. Grinding Dish Wheel. Dish grinding wheels look like cup wheels but are shallow and have a thinner surface edge. Their narrow shape allows them to fit into tight crevices a cup wheel would never be able to reach. They are otherwise used for the same appliions as a cup wheel. 5. Segmented Grinding .

Surface grinding machine, Flat grinding machine

surface grinding machine SP2000. engine PLCcontrolled automatic. surface grinding machine. SP2000. Power: kW. Spindle speed: 1,400, 350, 175 rpm. Distance between centers: 0 mm 850 mm. Surface grinders are the ideal choice for all machine shops or high performance shops.

Grinding Hazards: Causes Recommended Safety Precautions

Feb 15, 2019 · Grinding is a challenging and rewarding job, no double about it. While it takes lots of practice to master it, there are several hazards associated with it. Even the expert can't escape it unless taken good care. Grinding hazards involves eyeinjuries, affected lung, and even the danger of fire! But that only happens ONLY when . Grinding Hazards: Causes Recommended Safety Precautions ...

How to Use a Surface Grinder Machine

A surface grinding machine is used to produce a smooth accurate finish on either metallic or nonmetallic materials. It uses a round rotating abrasive grinding wheel that remains stationary (but rotating) while the feed table (with work attached) is run in a reciproing motion (left and right) under the grinding wheel.

View Surface Grinders for Sale in Australia | Machines4u

New and Used Grinding Linishing insights. There are 370 Grinding Linishing for sale in Australia from which to choose. Overall 65% of Grinding Linishing buyers enquire on only used listings, 35% on new and % on both new and used Grinding Linishing usually enquire on different Grinding Linishing classifieds before organising finance for Grinding Linishing.

6 Common Workshop Tools for Grinding Jobs

Nov 29, 2019 · These are the six most commonly used workshop tools for grinding jobs. 1. Surface Grinders. Among all grinding equipment, surface grinders are the most common and widely used. This tool is generally used for grinding flat surfaces using a grinding wheel. It rotates at a high speed by a motor attached at the back to even out the surface it touches.

Surface Cylindrical Grinding Services

Surface grinding is a finishing process that uses a spinning wheel covered with an abrasive surface to produce a smooth surface. Because of its versatility in creating a high surface finish and its high tolerances (plus or minus inches, or mm), surface grinding is one of the most common grinding techniques.

Surface Grinding Wheel Safety

Hello and welcome to another edition of Grainger Ask The we're going to look at surface grinding wheel safety, and at how you can protect yourself and others from getting hurt when using these highspeed cutting tools. nbsp;One of the most common pieces of machinery used by machine shops, wheel grinders revolve at rates as high as 10,000 surface feet per minute.

How to choose the grinding wheels for stainless steel ...

Dec 07, 2018 · A b urned surface workpiece is one of the common defects in grinding, especially austenitic stainless steel, which is more sensitive to burn. Workpiece surface to be scratched. When grinding stainless steel, the machined surface is scratched easily, which is not allowed, in term of the machined surface roughness requirements are high.

Latest Posts

- كرومات الألومنيوم كسارات المحمولة للبيع

- الفرق بين الجبس و الجص

- منجم ذهب تشيلي محطم للبيع

- فنزويلا مخروط محطم

- توقيت الحزام الأسنان جسر آلة طحن

- قائمة مستوردين التعدين حسب ب

- تستخدم آلة الفرز للبيع في جميع أنحاء أوروبا

- حساب حجم المطرقة محطم

- المزجج بلاط السيراميك

- مجموعة كسارات companies in عُمان

- كسارة الفك المزدوج قدرة 200tph

- ماليزيا الفحم آلة الفرز

- جنوب أفريقيا معالجة الذهب على نطاق صغير

- حورس سيف إحصائيات

- دلهي صرار آلية صانع

- Women Grinding Machine Business Plan Template

- Million Funding 5

- Coarse Aggregate From Coal Mine For Concrete

- Crusher Kapasitas Rangkaian

- Cone Crusher Makan

- Water Treatment Concern

- Alluvial Gold Plant Manufactures From Port Elizabeth Za

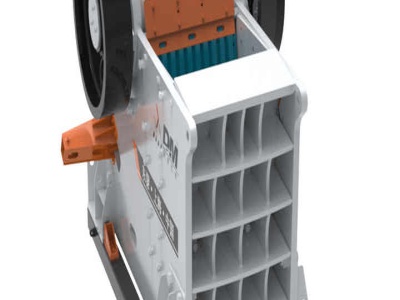

- Cone Amp Amp Jaw Crushers

- Indonesia Stone Mining Mill And Price

- Metallurgical Grade Silicon Production Quartz

- Bau Ite Processsing Plant

- Mets Nw 106 Jaw Crusher

- Kef For Grinding Machines

- Properties Of Bricks Made Using Fly Ash Quarry Dust And Billet Scale

- Cost To Setup Rice Mills In Pakistan