Waste Coal From Coal Washing Plant

Major Mines Projects | Clermont Mine

About % of ROM coal will be washed subject to market conditions with the remainder directly bypassed. The wash plant capacity will be around 300 tonnes per hour, utilising dense media cyclone and spiral gravity separation. Noncoal reject will be placed in impoundments and then buried with overburden waste.

Coal waste

· Coal mining and coal combustion in power plants produce several types of wastes: The mining process itself produces waste coal or solid mining refuse, which is a mixture of coal and rock.; The mining process also produces liquid coal waste, which is then stored in impoundments.; Pollution control equipment used for coal combustion produces coal ash or fly ash, as well as fluegas ...

Stronghold Acquires Second Power Plant

Aug 03, 2021 · By converting the waste coal into power to mine bitcoin, Stronghold has sought to restore the usability of geographical areas that AMD had previously damaged. In June, Stronghold raised 105 million in two private placements of equity securities and estimated to eliminate around 200 tons of waste coal for each bitcoin mined.

COAL WASHING POWER GENERATION FROM WASHERY REJECTS

Coal Washing Problems associated with Indian runofmine coal ¾Indian coal has drift origin, resulted in intimate mixing of mineral matter with coal, giving rise to the ash content ¾The coalash distribution in the coal matrix in Indian coal is so interwoven that coal is essentially required to

Waste treatment of ElMaghara coal washing plant by ...

Waste treatment of ElMaghara coal washing plant by flotation for beneficial reuse of its constituents in industry . ... The refuse of ElMaghara coal washing plant, in northern Sinai, Egypt, was one of these wastes which contains a considerable amount of coal fines and huge amount of clay. The main objective of this work is to recover the coal ...

coalwashrejects

Coal washery rejects are wastes resulting from washing coal, including substances such as coal fines, soil, sand, and rock. The coal washery rejects levy is adjusted annually according to the Consumer Price Index (CPI). The levy payment calendar for coal washery rejects provides details about levy periods and due dates for payment reports.

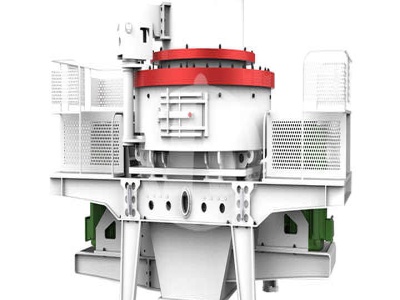

Coal Preparation Plant | Coal Preparation Process | Coal ...

Coal preparation plant is a coal processing plant that include a series of processes: raw coal screening, crushing, coal washing, separation, clean coal dewatering and slime recycling. Which can separate coal from impurities, remove mineral impurities from raw coal and divide it into different specifiions of products.

Effective utilization of waste ash from MSW and coal co ...

The solid byproduct from power plant fueled with municipal solid waste and coal was used as a raw material to synthesize zeolite by fusionhydrothermal process in order to effectively use this type of waste material. The effects of treatment conditions, including NaOH/ash ratio, operating temperature and hydrothermal reaction time, were investigated, and the product was applied to simulated ...

Comprehensive review on wastewater discharged from the ...

The huge amount of WW released by coal washeries (approximately 300–500 m 3 of effluent each day per plant) can be treated for reuse in coal washing and to reduce fresh water consumption, because, as per estimates, every 100 tonnes of coal requires 6 × 10 5 to 2 × 10 6 gallons (2,270–7,570 m 3) of water for washing .

Mineral Processing,Longwall Coal Mining,Coal Washing Plant ...

Mineral Processing Plant Design. As a technologydriven mining company, HOT can provide highquality Onestop Service for coal washing plant and mineral processing plants of gold, copper, lead, zinc, iron, barite and kaolin,etc. Contract Mining. HOT has a complete industrial chain of mining and selection engineering, and have the ability of EPC ...

Coal Washing Wastewater Treatment Process

02/12/2019 · Coal washing wastewater contains a lot of suspended solids, slime and silt, so it is also called slime water. The concentration of suspended solids in untreated slime water can reach more than 5000mg / L. Due to the hydrophobicity of coal itself, some micro pulverized coal in the coal washing wastewater is particularly stable in. Read more

Mining Equipment | MC

What is Coal Preparation Plant Coal preparation plant is a coal processing plant that include a series of processes: raw coal screening, crushing, coal washing,... 10 + Troubles and Troubleshooting of Hydrocyclones . For hydrocyclones, the troubles that often occur include abnormal supergranularity, failure to reach the cut point, unstable performance, blockage and so on. Below are 10 ...

Stronghold Acquires Second Power Plant

· By converting the waste coal into power to mine bitcoin, Stronghold has sought to restore the usability of geographical areas that AMD had previously damaged. In June, Stronghold raised 105 million in two private placements of equity securities and estimated to eliminate around 200 tons of waste coal for each bitcoin mined.

Waste coal utilization: a potential way to convert waste ...

01/01/2021 · As with other higher rank coal, sink and float experiments show the washing possibilities of waste coal. However, waste coal is easy to clean, which mainly depends on the content of neargravity materials at specific gravities (Khoonthiwong et al., 2020, Liu et al., 2016). Usually, the coal hydrophobicity is reflected by the contact angle and ...

Coal recovery from a coal waste dump

Coal was gravitationally separated from the waste material in a pulsatory jig and in a spiral washer including size fractions: 305 and 80 mm (this was crushed to a size < mm), respectively.

Dry Coal Processing Coal Washing Process

Typically coal processing is completed with water, which is a very costly and scarce resource requiring stricter permits to operate. The FGX dry coal washing process is proven successful, cost effective, environmentally friendly, and requires only an air quality permit. Coal mining typically results in the recovery of rock that ranges from ...

LabScale Combustion of HighMoisture Fuels From Peat ...

Jun 10, 2021 · The feedstock of a typical coal washing plant includes various raw and waste materials, such as coal mud and tailings, coal rock, fine and lowgrade coal [1, 2]. Coal slime, coal gangue, filter cakes and their mixtures are commonly referred to as coal processing waste.

coal waste dams | The Pop History Dig

Jan 31, 2019 · In addition to coal waste dams used in mining and coal washing operations, there are also more than 1,400 coal ash impoundments used mostly at or near coalfired powerplants in the In addition, coal wastes have also been dumped into abandoned deep mines and used to .

Coal Washing Plant Factory, Coal Washing Plant Factory ...

Coal Washing Plant Factory Select 2021 high quality Coal Washing Plant Factory products in best price from certified Chinese Pet Washing Plant manufacturers, Pet Bottle Washing Plant suppliers, wholesalers and factory on

Coal preparation plant process and equipment for coal washing

27/03/2019 · Taking a coal washing plant in Indonesia as an example, the coking coal preparation plant with an annual processing capacity of 4 million tons can increase the processing capacity per hour to more than 700 tons, and the power consumption, media consumption, fuel consumption, and water consumption are all reduced. At present, the whole plant ...

Coal Beneficiation Process Diagram

Apr 12, 2016 · The Coal Recovery and Cleaning by Flotation Flowsheet Diagram. The above flowsheets are based on existing small coal flotation plants. They illustrate clearly the simplicity and feasibility of adding "SubA" Coal Flotation as an additional process to small washing plants.

Coal waste: handling, pollution impacts and utilization ...

Jan 01, 2013 · coal waste management. Introduction. Poland is still one of the major producers of hard (bituminous) coal in the world and is currently still the largest producer in the EU. 1 In the 1980s, annual production was about 200 Mt, but from 1990 onwards, hard coal production in Poland started to decrease, so that by 2008 it was only 84 Mt.

Investigation of Production of Brick with Waste Coal ...

Wastes in coal quarries and coal power plants are significant issues. Coal washing plant tailings as waste coal powder is one of these issues. Today, their ecological and economical utilization, control and management are of main subjects for ongoing researches throughout the world. On the other hand, researchers still carry out intense investigations on the production of lightweight and ...

waste coal from coal washing plant

06/12/2012 · Coal Washing Plant – Parnaby Cyclones International. The natural medium coal washing plant is the most costeffective method of . and of recovering coal from colliery plant uses four types of . »More detailed

Coal Washing |

Coal washing Coal that comes from a mine is a complex mixture of materials with a large variety of physical properties. In addition to the coal itself, pieces of rock, sand, and various minerals are contained in the mixture. Thus, before coal can be sold to consumers, it must be cleaned. The cleaning process consists of a number of steps that results in a product that is specifically suited to ...

Latest Posts

- صنع في فرنسا

- فصل الذهب والنحاس

- شراء بومباي الأعشاب

- الصين براميل فاصل

- ذروة مخروط محطم الفيروز

- مصنع تعدين الذهب للبيع في الولايات المتحدة الأمريكية

- مطحنة رمل تاميل نادو

- كسارة الفك الزاحف

- أنواع مختلفة من الخلطات الخرسانية

- شركة المحاجر المتحدة

- الحجر الجيري سحق الاسمنت

- ماليزيا مسحوق الكالسيت

- أفضل آلة صرار

- جنوب أفريقيا حجر سحق آلة السعر فينوس

- Sinter And Pellets

- Crushing Equipment Cv

- Company Profile Mining And Coal

- Granite Porphyry Crusher Manufacturers

- Dry Powder Mi Ing Pile Testing Project

- Ball Amp Amp Pebble Mills For Sale

- Conveyor Belt Heater

- Gregate Crushers Crusher For Sale

- Pigment Grinding Vogel

- Manufacturer Of Ball Mill In Manila For Small Miners

- Crusher Company Cone

- Fujian Lime Mine Transfers

- Machine In Bolivia Grinding Mill

- Introduction Of A Jaw Crasher

- Machinary Used In Cement Industry

- Hp 700 Hydraulic Cone Crusher Of Usa