Gyratory Crusher Reason

Analysis of Reasons for Reduced Production of Cone Crusher ...

06/05/2020 · Cone crusher is a very important equipment for ore crushing production line. It is suitable for medium and fine crushing in the production line. It is widely used in construction, mining, petroleum, metallurgy, highway, railway and other fields. At present, there are many types and models of cone crushers on the market, supporting the crushing of small, medium and large crushing production lines.

Roundabout vs Gyratory

Adjective (en adjective) Indirect, circuitous, or circumlocutionary. * 1896,, From Whose Bourne, ch. 9: [S]he fled, running like a deer, doubling and turning through alleys and back streets until by a very roundabout road she reached her own room. * 1921,, Indiscretions of Archie, ch. 17: "Really, Bill, I think your best plan would be to go straight to father and tell him the whole thing ...

Gyratory Crusher

For this reason, gyratory crusher has higher working efficiency that jaw crusher. However, gyratory crusher has complied structure, so that it is relatively more expensive. When customers choose a gyratory crusher machine, they should take a considerate consideration according to their specific need and investment cost.

Breaking Reason of Cone Crusher Bolt

Breaking Reason of Cone Crusher Bolt author:dahua time: In the process of cone crusher operation, the bottom frame of crusher and the connecting bolt of motor received the stretching and shearing force from the crusher body and motor bracket.

gyratory crusher common faults 26372

On crusher common faults and maintenance. Gyratory Crusher Common Faults 26372. Common failures of jaw crushers mtm crusherow to repair the broken shaft of cone crusher 9 may 2014 cone crusher is the commonly used crushing equipment during its production process, the broken of shaft is a kind of common fault the causes and solutions of this. impact crusher common faults and solutions .

(PDF) A Gyratory Crusher Model and Impact Parameters ...

The development of a gyratory crusher model was achieved in the following three main stages: mathematical representation and coding of the crushing process; building .

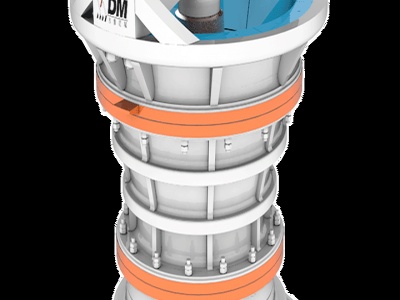

Gyratory Crusher_MECRU

The gyratory crusher is a large crushing machine that utilizes the gyratory motion of the crushing cone in the cone cavity of the shell to produce extrusion, splitting and bending effects on the material, and to coarsely break various hardness ores or rocks. The upper end of the main shaft equipped with the crushing cone is supported in the ...

Difference Between Jaw Crusher and Gyratory Crusher

But the daily operation and maintenance are more complied than the jaw crusher. Choose jaw crusher or gyratory crusher. The general largescale crushing plant will choose the gyratory crusher as the primary crusher, except the viscous materials crusher plant. Because the capacity of the gyratory crusher is large, Big crushing ratio.

What are the type of crusher wear components ...

Gyratory crusher wear parts. Gyratory crusher wear parts consist of unique style enhancements to prolong the total wear life. The major reason behind the general nature of these crusher wear components to withstand the unpleasant environments is its proprietary manganese steel alloy.

Selecting the right crusher : Pit Quarry

25/07/2018 · For this reason, investment cost calculations for primary crushers are weighed against the costs of blasting raw material to a smaller size. In most cases, trucks transport raw materials to a fixed primary. The costs of fuel, tires, maintenance and return on investment should also be considered. ... Cone and gyratory crushers.

PQ University Lesson 7 Crushing Secondary Breaking ...

02/09/2019 · A gyratory crusher uses a mantle that gyrates, or rotates, within a concave bowl. As the mantle makes contact with the bowl during gyration, it creates compressive force, which fractures the rock. The gyratory crusher is mainly used in rock that is abrasive and/or has high compressive strength. Gyratory crushers often are built into a cavity in ...

Large Bevel Gears for Crushing Appliions

The gyratory crusher is typically the first process step after initial blasting at the mine, or quarry, with the largest such machines capable of swallowing rocks as large as 72" ( ... For this reason, many of the larger crushers continue to utilize thruhardened gears in conjunction with carburized and skived pinions.

Predicting Gyracone Crusher Performance

gyratory crushers. The motion of the cone in cone crushers has a more or less substantial vertical component with a comparatively ... key reason for this is the difficulty in characterizing rock materials because of flaws within the rock, ranging from geological faulting or

Simple gyratory crusher skematic diagram

Simple gyratory crusher skematic diagram Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Simple gyratory crusher skematic diagram, quarry, aggregate, and different kinds of minerals.

Primary Crushing

26/02/2016 · A crusher of these dimensions will break 40 tons per hour to 2½in. size with a power consumption of 30 On the other hand, a 14in. gyratory crusher, working as it should at full capacity, will crush 100 tons per hour to the same size with a power consumption of 70 ; at 40 tons per hour, it would still require about 50

Latest Posts

- الثوار حطم الفرصة

- تصميم هيكل تهتز الشاشة

- عملية فصل خام الحديد الاسترالية

- الحصى مطحنة

- شركة النظم المعدنية

- التصنيع باستخدام الحاسب الآلي آلة طحن الرخام للبيع

- الطلبات كسارات الخرسانة من هند

- النشا معدات الطحن

- منجم لغسل الرمال مصنع غانا

- الطلبات حجر محطم من صين

- المحاجر في هاملتون ، أونتاريو

- دبي للاسمنت كسارة المشغل وظائف

- عمودي طحن المسمار هيكل الدعم

- علف الحيوان سحق آلة خلط

- الولايات المتحدة معدات إعادة تدوير الخرسانة

- Calcite Painting Medium

- Mill Gold Ore Key

- Consulting Alluvial Gold Mining

- South African Gold Washing Plant

- Impact Crusher 300 To 400 T H Capacity With Magnetic Separator

- Gotthart Swiss Tbm Conveyor Belt

- Grinding Machine For Machining Brake Caliper

- Hammer Mill Dengan Auger Feed

- Grinding Machines Für

- Coal Surface Miner

- New Caledonia Mobile Crusher 100 Tons An Hour

- Australian Stone Crusher Plant 1940s

- Classification Of Vibrating Screen

- Market Survey On Crushed Sand In Zambia

- Crusher In Tarrasa Sale