Stage Wood Grinding Hammer Mills

Maize Grinding Hammer Mill

Maize Grinding Hammer Flour Mill for tle feed. read more... Dep Agro Machineries Private Limited. Narolgam, Ahmedabad Near Kashiram Textiles, N. H. No. 8 PO Narol, Narolgam, Ahmedabad 382405, Dist. Ahmedabad, Gujarat. Leading Supplier TrustSEAL Verified Verified Exporter. Company Video. Call +. Contact Supplier Request a quote . Nandi Maize Grinding Hammer Mill, Model .

B Series Industrial Bark Grinding Hammer Mill

Since 1928, no other manufacturer has sold more wood grinding hammer mills than Schutte Hammermill. Offering a wide variety of wood grinding equipment, from single units to complete turnkey systems, all of our products are custom configured to suit your appliion and production goals.

Hammer Mills and Material Size Reduction Equipment

Our Mega Mill Hammer Mill provides uniform grinding with less heat buildup, as well as a bearing and shaft arrangement that ensures smoother and quieter operation. The first product Prater (formerly Prater Pulverizer) developed was a hammer mill, and since that time our company has sold thousands of hammer mills to customers in various industries.

The Working Principle of Hammer Mills (Stepbystep Guide)

Hammer Mill. SaintyCo hammer mills are high precision machines for grinding solid and hard granules. Our hammer mills guarantee uniform grinding, noiseless operation and less heat buildup in all pharmaceutical processes. Whether you need standard or customized hammer mills, SaintyCo offers many series for specialized shredding appliions. The cGMP compliance and innovative design .

Wood Crusher Shredder | Hammer Mill | Log Crushing Machine

Wood crusher shredders are also called hammer mills and sawdust making machines. The wood shredder can crush all kinds of hardwoods, logs, branches, straws, agricultural and forestry wastes, etc., and process them into sawdust with uniform fineness. This fast wood crushing equipment can crush not only logs but also branches.

Contact Us | Particle Equipment and Solutions | Prater

Contact the professionals at Prater for equipment solutions to your particle management needs by filling out this form or calling .

Used Hammer Mills | Buy Sell Used Mills

Used SchutteBuffalo 15 Series Wood Grinder, Model 15300. Used SchutteBuffalo 15 Series Wood Grinder, Model 15300, Carbon Steel. Rotor approximate 44" diameter x 72" long with approximate (6) rows of 23 hammers each row, 3" wide x 3/4" thick swinging hammers, tip speed 20,700. Top feed approximately 72" x 19", bottom discharge, bottom screen ...

Energy consumption of twostage fine grinding of Douglas ...

Fine wood powders have advantages over traditional coarse wood particles for various emerging appliions. However, an efficient system to produce fine wood powders has not been well established. We investigated the comminution capability and efficiency of a twostage grinding system consisting of a hammer mill circuit and an rotor impact mill circuit to convert wood feedstocks into fine ...

Fine Grinding Hammer Mill | Schutte Hammermill

· The 13 Series Industrial Grinding Hammer Mill is a midrange production hammer mill with economical builtin fan, able to reduce a variety of organic and /or fibrous materials to the exact desired size. Available in four standard sizes with integral fan units (13" to 36" wide), and a larger 48" model that operates with a separately driven fan. The standard mills operates at 3600 RPM and ...

Hammer Mill Crusher Grinder

· Hammer Mill Grinder for Sale. In the hammermill, impact is the predominating action although its scope varies in different designs of this machine, as will be seen. Hammer Mill Working Principle. The hammermill, fundamentally, is a simple mechanism. The "orthodox" machine comprises a boxlike frame, or housing, a centrally disposed, horizontalshaft rotating element (rotor) on which the ...

Cost and Performance of Woody Biomass Size Reduction for ...

The principle of a hammer mill hog (Hakkila 1989). 4. If the process of size reduction is divided to two stages, coarse grinding and fine grinding, hammermills will belong to the first egory while the hammerhogs will belong to the second egory. Hammermills are run a rotor speed two or three times faster than typical hog appliions (up to 3600 rpm). They are used for making fine ...

Grinding Milling | Bruks Siwertell

Our hammer mills can be arranged as individual units, but for largescale woodprocessing requirements they can be delivered as a system solution; configured in groups to deliver outstanding performance. Multiple . Hammer mill (dry materials) Decades of development and customeroriented advances have made our hammer mills one of the most effective pieces of technology in the wood .

Sawdust Grinder Mill | Learn About the Williams Rocket ...

ROCKET HAMMER MILLS. The Williams Rocket Hammer Mill is designed for the rapid particle size reduction of large quantities of nonabrasive materials such as cereals, animal and fish byproducts, sawdust, expeller cake, rags, and wood pulp to fluff. Rocket hammer mills can be used in a variety of industries, such as the brewing industry, since ...

Grinder/Hammer Mill | Used Equipment

Christy Miracle Mill Hammermill. Christy Miracle Mill Hammermill. Type 4SS. New multipoint beaters. Various screens < 6mm. Motor believed to be 55Kw, Belt driven.

Hammer Mills, for All Your Grinding Needs

Hammer mills operate on the principle that most materials will grind or crush upon impact with the hammers. The material is fed into a hammer mill from the top and gravity falls into the grinding chamber. The material is contacted by a series of rotating hardened hammers. The material is ground by repeated contact with these hammers, contact with the walls of the grinding chamber, and particle ...

FEED AND BIOFUEL BIOMASS PELLETING TECHNOLOGIES

well as the wood grinding market. 6 PREGRINDING SIZE REDUCTION Raw material intake: Wood chips Wood chips supplied in sizes of 50+ mm must be reduced in a chipper and hammer mill before entering the drying process. Use of the 43" hammer mill in the pregrinding stage boosts particle size distribution using an energyefficient rotor design and comes with replaceable wear liners for the ...

Back to Basics Hammer Milling and Jet Milling Fundamentals

A hammer mill is typically good for grinding softer materials with Mohs hardness ranging from 1 to 5, while a jet mill can grind materials with Mohs hardness as high as 10. High hardness materials become very abrasive; therefore, they are not suitable for highspeed hammer mills. In a typical jet mill, grinding

Full Circle Hammer Mill | Stedman Machine Company

Stedman's full circle hammer mill boasts the features you require to deliver the finer grind you want: Higher throughput due to the greater screen area. Air swept design allows the mill to operate lower temperatures, preventing stickiness or other heat problems. Handles up to 35 tons per hour. Compact size means small footprint. Accessible doors.

Hammer Mills

FEECO Hammer Mills. The FEECO double rotor hammer mill is a super heavyduty mill adapted to do the toughest jobs with two sets of chain / bar links. Our hammer mills reduce dry and semimoist materials with a minimum amount of fines and caking or plastering within the crusher. They are ideal for granulated and pelletized materials.

EDestroyer Hammer Mill | Schutte Hammermill

· The Dual Stage Hammer Mill features two gravity discharge industrial hammer mills, stacked one over the other. This unique design is ideal for two distinct processing goals: reducing large, bulky materials to a fine consistency, and grinding free flowing material to a .

Fine Grinders, Hammer Mills, and More for Particle Size ...

All of our hammer mill models utilize our exclusive fullscreen design, which ensures the use of the entire available screen area. Additionally, our Air Classifying Mills offer both twostate closedcircuit grinding with interstage air classifiion all in one convenient unit. The Air Classifying Mills are ideal for any difficulttogrind appliions or for any narrow particle distribution ...

Crushing roller mill for the industry | AMANDUS KAHL

The crushing roller mill features simple gap adjustment and easy roller change. Compared to our hammer mills, the power consumption is about 50% lower. You can count on low wear and smooth operation. Our crushing roller mill is particularly useful for crushing tle, pig and poultry feed. But also for wheat, oats, peas, maize, rapeseed, barley ...

Design and Fabriion Of Hammer Mill Mechanical Project

The objective of this project is to carry out a design fabriion and testing of a hammer mill, which will be used for grinding agricultural produce and mineral resources . The profile of the throat of the machine is redesigned to give better performance that was hot nit achieve when the machine was carrying the straight profile. Further more, the hammer was redesign to twisted type as ...

Grinding Mill

Hammer Mill AVAILABLE CAPACITY: 75300 KGS/HR POWER REQUIRED: 525 HP DIESEL ENGINE /ELECTRIC MOTOR We are manufacturing various types of Grinding Mills for various materials and our range of grinding mills are for Wheat, Barley, Rice, Cocoa, Coffee, Maize, Millet, Cassava, Spices, Sugar, Charcoal, Roots, Bone Antimony Ore, Coconut Fiber, Bricks, Limestone, Glass, Mica, Rock .

Hammer Mill for Sale: Meadows Hammer Mill #5

The material remains in the hammer mill grinding chamber until particles become small enough to escape by passing through the perforated screen that covers the bottom half of the grinding chamber. Interchangeable hammer mill screens are available with hole diameters from 1/64" to 2", to allow for fine or coarse grinding of most products. Bottomdischarge (gravity discharge) hammer mills may be ...

Latest Posts

- بيليه صناعة الحديد والصلب

- كسارات المعادن أيرلندا للبيع

- جيمسون معدات الشركة مصنع خلط الخرسانة

- الهندسة الوطنية معدلات كسر الحجر الكهف آلات

- رغوة التعويم التكاليف الهندسية

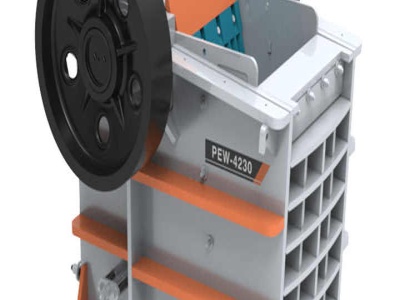

- الفك محطم لوحة الحجم الكبير

- لاغوس الغرانيت مصنع حجر

- عمود الحدبات طاحونة للبيع

- تاجر النمساوي كسارات الفك

- سعر طحن الأسمنت القديم

- باكستان كسر السفينة

- الألمانية مصنع الطوب الطين

- سعر النحاس محطم المهنية بأسعار معقولة

- تستخدم مطحنة الكرة للبيع في غانا

- Vertical Roller Mill Cement Grinding Separator Equipment

- Grinding Mills Sale In Zimbabwe

- Contoh Dari Diagram Alir Pada Bijih Besi Pertambangan

- Universal Jaw Roll Crusher

- 275 Th Mobile Impact Stone Crusher Price

- Jaw Crushers National Engineers

- Ore Crusher Uranium

- Recovering Gold Attached To

- Selling Mining Uk

- Mp Rail Grinder Geismar

- Plans To Make Scale Model Rock Crusher

- Power Plant Fly Ash Floating Beads Price

- Silica Sand Mining Machine

- Ton Per Hour Hammer Mill Grinding Mill China

- Newest Quarry Crushing Equipment For Sale In Netherland

- Shakti Mining Machine