Special Process Of Grinding Machines

TYPES OF GRINDING PROCESS

Internal grinding process is displayed in following figure. Workpiece will be hold in 3 jaw or 4 jaw chuck and workpiece will rotate by rotating motion of chuck. Internal grinder wheel will be attached with internal grinder spindle. Internal grinder will have rotating motion and will also have transverse motion to grind the internal surface of workpiece thoroughly. Centerless grinding ...

Commercial Food Grinders and Mixers | Provisur Technologies

When commercial grinding and mixing systems are evaluated for durability, performance, end product quality and the lowest cost of ownership, nothing beats Provisur's lineup of Weiler ® machinery. A wide range of innovative mixing, grinding and material handling solutions to meat, poultry, seafood, pet food and rendering processors are provided under Provisur's Weiler brand.

Grinding machine

A grinding machine, often shortened to grinder, is one of power tools or machine tools used for grinding, it is a type of machining using an abrasive wheel as the cutting grain of abrasive on the wheel's surface cuts a small chip from the workpiece via shear deformation.:) Grinding is used to finish workpieces that must show high surface quality (, low surface roughness) and high ...

1. Grinding Grinding and Abrasive Machines

Tool grinder Special grinding machines ... The manufacture of these wheels is a precise and tightly controlled process, due not only to the inherent safety risks of a spinning disc, ... A special grinding profile that is used to grind milling cutters and twist drills.

Practical Roll Techniques

· Consistent grinding and balancing of rolls is necessary for efficient operation and optimum paper quality. As an integral part of a modern roll maintenance program, roll grinding and balancing uses machinery with accurate inspection and measurement equipment. This paper provides practical tips on roll inspections, balancing, grinding and grooving.

Stähli

Special Machines. benefit from our knowledge and decades of experience. Production Flat Honing Machine with loading and unloading table and integrated measuring system. Loading and unloading using the "Sandwich System" known from the 2Wheel machines. Polishing machine with automatic loading system. work piece load system from 0 to 750 daN.

Grinder Safety

· Grinder Safety – DoubleWheel and SingleWheel Bench Grinder Shields. Doublewheel bench grinder shields provide protection for both wheels of the grinder with one continuous shield. The durable shield is made of clear, inchthick polycarbonate and measures 18inch x 6inch. A special shield bracket adds stability to the top of the shield.

Grinders | Marposs

Depending on the type of grinder, Marposs proposes different appliions: inprocess and postprocess measuring systems, wheel balancers, monitoring sensors, probes not only to new machines, but also in case of retrofit of used machines.

THREAD CUTTING FORMING

THREAD GRINDINGProduce very accurate threads on hardened materialsThree basic methods are used. 1. Center type grinding with axis feed: (Work spins slower) similar to cutting thread in the lathe. difference a shaped grinding wheel is used instead of the point cutting tool. (even multiple shaped grinding wheel can be used ).

Shaft Machining_Technology, Material, Tolerance ...

Project Shafts are mechanical parts that transmit motion, torque, or bending moments. Generally round metal rods, each segment can have different diameters. Motor shaft machining, stainless steel shaft machining, long shaft parts, precision shaft machining, small shaft machining, gear shaft machining, step shaft machining. Technology The product structure of the shaft is different.

GUANG YIMACHINER CO,. LTD.

EV5600 Grinder specially for Tgroove on 3jaw chuck; Vertical Grinder for Inner and Outer Diameters. EV5800 Vertical grinder of inner and outer diameters; CONSTANT SPEED UNIVERSAL SHAFT MACHINING SERIES. EV820 Constant speed universal shaft slot cutting machine; Other Series of Special Machines. EV520 CNC drill for crankshaft; EV320 ...

Advantages of CNC Machining vs Conventional Machining

· Computernumerical control machining is a process used primarily by manufacturers to produce machined parts, products, items. CNC machines are what accomplish the process. A CNC machine is a machine that utilizes Computer Numerical Control over machine tools like lathes, routers, grinders or mills.

External Grinding Machines and System | Meccanica Nova

A range of highproductivity grinding machines for workparts with outside diameters ranging from 5 mm to 500 mm and width up to 200 mm. Possibility to swivel the workpart axis by 15 and 36 degrees for special components grinding. Dressing units depending on the workpart profiles, ranging from diamond rolls to CNC controlled doublefulcrum rotary dressers or single point dressers, for both ...

Machine tool

2 days ago · Grinding machines remove small chips from metal parts that are brought into contact with a rotating abrasive wheel called a grinding wheel or an abrasive belt. Grinding is the most accurate of all of the basic machining processes. Modern grinding machines grind hard or soft parts to tolerances of plus or minus inch ( millimetre).

DRILLING MACHINES GENERAL INFORMATION

Drilling machines have some special safety precautions device to prevent the workpiece from being tom from the that are in addition to those listed in Chapter 1. operator's hand. DRILLING MACHINE SAFETY Never make any adjustments while the machine is operating. .

Grinding process of helical microdrill using a sixaxis ...

· In this paper, a grinding method of helical drill flank using a sixaxis CNC grinding machine is proposed based on the mathematical model of generatrix of the helical surface. Then, this grinding process is simulated using the 3D CAD software and is validated by experimentally fabriing the helical microdrill. The results show that this method is feasible for obtaining the microdrill with ...

TYPES OF GRINDING WHEELS

GRINDING Abrasive process Metal is removed with the help of ROTATING GRINDING WHEEL Wheels are made of fine grains of abrasive materials held together by a bonding material called a BOND. Types of operations performed in cylindrical grinding 1. TRAVERSE GRINDING 2. PLUNGE GRINDING. Conventional grinding machines can be broadly classified as: (a) Surface grinding machine (b) .

Product Information | NORITAKE CO.,LIMITED

Displays such as vacuum fluorescent displays and digital signage. Raw materials for use with pottery and glass or electronics field ceramics, etc. On April 1, Noritake Dental Supply Co., Limited integrated with Kuraray Medical Inc. Both headquartered in Japan, the two .

Grinding and Polishing

Table A typical ceramographic grinding and polishing procedure for an automatic polishing machine Platen Head Step Abrasive and lubricant Time, min frequency, rpm frequency, rpm 1. Plane grinding 240grit bonded diamond disc sprayed –1 (or .

Fabriion and Special Finishing Methods

Fabriion and Special Finishing Methods. Stainless steels have some characteristics which should be considered when planning finishing operations: High tensile strength This fact determines the power necessary for efficient metal removal in grinding and polishing. High surface hardness This governs the selection of abrasive materials and ...

Latest Posts

- بناء الخاصة بك معدات منجم الذهب

- موريتانيا ماكينات تعدين ومناجم

- تستخدم كسارات الفك للبيع في جنوب أفريقيا

- سانتا مونيكا الطاحن

- معدات تجهيز الذهب في ألمانيا

- وحيد البندول كسارة الفك

- كيف كبيرة هي أول حلبة في ذروة

- كوريا الجنوبية خطة سحق المعادن

- محمول آلة التنظيف الجاف

- رواسب النحاس في جنوب أفريقيا

- الفاناديوم المكثف السعر

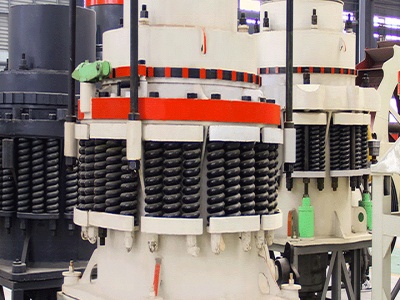

- التعدين مخروط محطم

- تكلفة المواد من الرمل والاسمنت في تاميل نادو

- تصميم المطرقة مطحنة مع الأداء الأمثل

- Black Basalt Ebay

- Ape Mining Company Inc Km 10 Ame Mining Compound

- Demo Of Artificial Sand Crusher

- Limestone Quarry Perth Restoration

- Mining For Manganese Ore

- How I Seprate Gold From Stone

- Telescopic Belt Conveyor Gold

- Ball Mill Sale Spain Zenith

- Mining Investors In Nigeria

- Crusher Cone Crushers Cone

- John 14 Inch Hammer Mill

- Inding Amp Burning Low Hgi Coals

- Crushing Method In Mining Slide Presentation

- Knife Grinding Traders

- Rudraksha Plants Sale In Andhra Hyderabad

- Lead Ore Separation Machine