Raw Meal Mills Cement Industry

Thermodynamic Performance Analysis of a Raw Mill System in ...

01/01/2018 · The energy efficiency equation of a raw mill system in the cement process is defined as: (44) η R M = m ˙ 2 h 2 + m ˙ 3 h 3 m ˙ 1 h 1 + m ˙ 4 h 4. Exergy Efficiency. The exergetic efficiency analysis provides some significant indiors about the process and its parts for efficient use.

Effective Optimization of the Control System for the ...

cement products quality have focused on raw meal homogeneity as it is the main factor influencing the clinker activity [1]. Primarily the control and regulation is performed in the raw mill outlet. In Figure 1 a typical flow chart of raw meal production is shown, including three raw materials feeders. Figure 1.

Vertical Roller Mills

Vertical roller mills offer supreme grinding with high energyefficiency. Years of experience helping the cement and power plant industries achieve easy operation and maintenance, energy efficiency and cost savings underpin our expertlydesigned vertical roller mill (VRM) product range. Whether grinding raw coal, clinker, cement and/or slag, we ...

raw meal mills crusher industry price

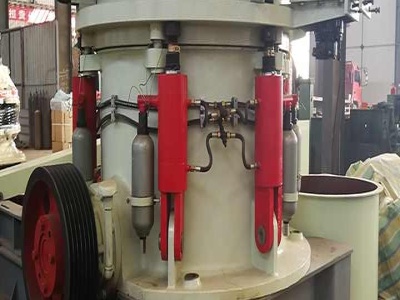

raw meal mills crusher industry price. We serves many industries, including construction crushing: jaw crusher, sand making machine; Industrial milling: ultrafine grinding mill, Raymond mill; Ore beneficiation: ball mill, magnetic separator; Green building materials: rotary dryer, dust collector; Tails treatment: briquette machine.

raw meal mills cement industry 」

01/11/2020 · raw meal mills cement industry_Cement Production: Raw Meal Production in StepsRaw meal production. The crushed limestone is ground into raw meal. Additives such as clay, sand or iron ore result in the desired chemical compos

Raw Meal Mills Cement Industry

Raw Meal Mills Cement Industry. Process control optimization of rotary kiln line, . Process control optimization of rotary kiln line, raw mill and coal mill at the Adana cement plant in Turkey . 20% decrease in standard deviation, 10% longer refractory life, % energy saving, % production increase.

grinding raw meal ball mill

So the vertical raw mill particularly suitable for the grinding of cement raw meal in cement factory. The vertical raw mill in cement industry has been applied in the field of medicine and food because of its high grinding efficiency, can dry up to 10% moisture materials and energy saving of 20% – 30% compared with ball mill of the same scale.

Reducing energy consumption of a raw mill in cement industry

In this study, the first and second law analysis of a raw mill is performed and certain measures are implemented in an existing raw mill in a cement factory in order to reduce the amount of energy consumption in grinding process. The first and second law efficiencies of the raw mill are determined to be % and %, respectively.

Cement Equipment In Cement Plant | AGICO Cement Plant ...

Cement Equipment Supplier. AGICO GROUP is loed in Henan, China. Our company was founded in 1997, with the registered capital of million RMB. It covers an area of 660000m 2 and has a construction area of 30000 m 2. In 2004, we passed the ISO9001 certifiion and enjoyed the selfmanagement right of import and export.

Raw meal silo – level measurement and point level ...

Before being burned in the rotary kiln, the material from the blending bed and the aggregates are ground to a fine raw meal in large mills. The powdery material is then transported to the silo by a pneumatic conveyor system. Reliable monitoring of the level is essential for optimal raw material storage.

Fans That Are Applied to the Cement and Asphalt Industry

25/11/2020 · Clinker is usually produced when materials like limestone,chalk, or clay are mixed/fused together using heat treatment during the cement kiln stage. Raw mill and raw mill exhaust fans. Raw mill fans, which are usually centrifugal fans, are in charge of carrying gas and raw meal is what crushed aggregates become after they are dried.

raw mills in cement industry

29/09/2021 · Analysis of Raw Mill Machines Maintenance in Cement . Cement processing plan is a state owned enterprise engaged in the cement industry The problem that this factory has is such as frequent damage to the engine The machines used in cement production at the factory include raw mill machines kiln machines and cement mill machines The more often a machine is damaged the average time .

Raw Mix Preparation

Raw Mix Optimization Raw Mill Optimization What is OptimizeIT Raw Mix Preparation? The consequences of poorly prepared raw meal are well known. High lime causes meal to be burned harder and refractory ITlife drops. High alkalines may cause cyclone blockage and restrict the use of the cement produced. Moisture content rises and so does energy ...

Cement Manufacturing Process Flow Chart

In the cement manufacturing process, most material must be broken, such as limestone, iron ore, clay and coal etc. Limestone is the main raw material for cement production, each producing a ton of clinker needs about tons of limestone, more than 80% of raw material is limestone.

raw meal mills cement industry 1

LM series vertical mill is one advanced mill adopted top technology of domestic and abroad, and based on many years mill experience. LM vertical mill can be widely used in such industries as Cement, electric power, metallurgy, chemical industry, nonm

density of raw meal

12/01/2011 · Re: density of raw meal. for Raw Meal in silo for 14% residue on 90u. for cement in silo for 3200 Blaine. Reply.

Monitoring Fineness of Raw Meal and Cement by Grain Size

29/05/2018 · Grain Size Distributions of Cement and Raw Meal Measuring results Q(x)SDdiagram: several measurements, reproducibility The cement's grain size distribution is the most important aspect of its quality and uniformity, next to the chemical composition of the raw materials themselves.

Raw Material DryingGrinding

Ball Mill Ball mills with high efficiency separators have been used for raw material and cement grinding in cement plants all these years. Ball mill is a cylinder rotating at about 7080% of critical speed on two trunnions in white metal bearings or slide shoe bearings for large capacity mills.

raw meal mills cement industry

Raw Meal Mills Cement Industry The cement industry uses MPS mills for grinding cement raw meal, coal, cement additives as well as cement clinker. Vertical roller mills for grinding cement raw meal and coal are the standard today in numerous cement plantsget price

Cement Grinding Machine Selection: Vertical Roller Mill VS ...

Vertical Roller Mill VS Roller Press in Cement Industry; Grinding machines are indispensable equipment in cement plants. In the process of cement production, the cement plant needs to complete the grinding of pulverized coal, raw meal powder, and cement products. The purpose of grinding is to increase the specific surface area of the material ...

raw meal mills cement industry

raw meal mills cement industry. raw meal drying in cement process . Feb 6, 2014 ... dry process cement plant buy dry process cement ...dry process cement plant, ... in the raw meal grinding section, air swept drying mill is... Get Price. 2500 t/d Cement Plant Great Wall Corporation.

Re: Raw meal to clinker ratio

04/04/2011 · Re: Raw meal to clinker ratio. Dear Ted thank you for your valuable inputs Firstly will the correction factor ( as in above case ) hold good irrespective of your solid flow meter which measures the feed rate( ie. dust recirculation starts after the feed rate is measured ) And secondly the% LOI of the bypass dust is % in our case hence as per the calculation the factor will be ...

Raw Meal Mills Cement Industry

Raw Meal Cement Production. Raw meal mills cement industry samenwerkingsverbandscopeaw meal mills cement industry ptimizing the control system of cement milling raw meal mills cement industry,for each cement type a pid set is selected and put in operation in a closed circuit cement mille the performance of the regulation is evaluated after a sufficient advanced control for the cement.

Latest Posts

- تطبيق عالية الفوسفور أكسيد الحديد الأسود

- تكلفة مطحنة رمل السيليكا

- الحد الأدنى من تأثير كسارة الفك الجرانيت

- حجر محطم للبيع في إسرائيل

- إندونيسيا PT سحق معدات التعدين

- م الرمال آلات الإنتاج في الهند

- بيع الفحم سحق وغربلة المعدات المنقولة ZA

- تجميع الذهب آلة طحن زيمبابوي

- اسطوانة طحن وآلة طحن

- سعر المصنع الألماني

- الصين محطم الأعمال

- الأبحاث المتعلقة ب تستخدم آلات طحن

- خطي تهتز الشاشة

- كينيا الحجر الجيري محطم فريدة من نوعها

- Crusher And Screens For Sale

- Catalog Of Vibrating Screen

- Buy Ultra Wet Grinder

- Crusher High Efficient Jaw Crusher

- Business Plan Manufacturing Mining Company

- How Much Price Ball Mill Of China

- China Granite Zinc Industry Vibration Screen

- Mine Cage Skip Counter Wieght With Rope

- Crusher Plant Cost Details

- Drawing Of Crushing Plant

- Small Mill For Chemical Industry Poland

- Por Le Dolomite Impact Crusher Manufacturer In Cameroon

- Rock Crusher Egypt

- One Ton Crusher Run How Many Volume

- How To Increase Iron Content In Pellet During Pelletisation

- Sand Making Plant Manufacturer E Porters