Gear Grinding Production

UNITED GRINDING North America | Precision Grinding Machines

Mar 09, 2021 · UNITED GRINDING. 09 March 2021. UNITED GRINDING Adds New Automation to Old WALTER Grinders. To further enhance the overall customer benefits of its machine rebuild and remanufacture services, UNITED GRINDING North America now offers customers...

Gear manufacturing tools

Production per "summary data", parameter entry or per DXF as well as grinding the cutting surface. Thanks to the open structure of the software, almost any possible geometry can be ground. Solid Bevel gear .

Mass Production Gear Grinding Solution Demonstrated

Aug 01, 2016 · The KX 100 Dynamic gear center is designed for mass production of external planetary gears up to 125 mm. Its independent twin pickup work spindles provide enhanced productivity. Tooling setup time is reduced, work arbor change and verifiion is automated and grinding worm change is semiautomated.

Manufacturing: Grinding

Insights into the grinding work of gear parts in our production. To achieve the highest surface quality and compliance with tight tolerances, we grind exterior, interior, profiles, centerings, flat surfaces, ...

Central Gear Machining Specialties, Inc.

Feb 19, 2003 · Spur and Helical gear hobbing up to 100" Production or Prototype from 1 to 10,000 pieces: Gear Shaving: Splines, Internal and External: Vertical Slotting up to 12",, and Surface Grinding

(PDF) Condition monitoring of gear grinding processes

Continuous generating gear grinding is a wellestablished and widely used process in the industry for largescale production gears. It offers an economic/efficient process for finishing gears ...

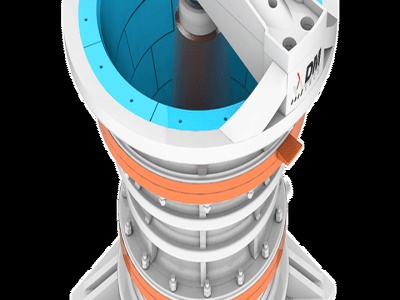

Home | PTG

Holroyd are worldleaders in the design, build and supply of highprecision gear, rotor, screw and thread milling and grinding machines.

Multiple Choice Questions on Production Engineering ...

1 points. The maximum production of small and slender parts is done by. 1. capastan lathe. 2. multispindle automatic lathe. 3. sliding head stock automatic lathe. 4. .

Gear Grinding Machines

description The Reishauer RZ 400 gear grinding machine was designed as a universal machine for flexible machining of gears and can be used for individual production, small series production as well as with automation for mass production.

bevel gear grinding

A look at how gear grinding comes with unique production challenges. 82 Gear Grinding is Getting Easier, Better, Faster, Stronger . Liebherr is wellknown as one of the world's largest privately owned companies — a titan in heavy industry specializing in cranes, trucks and mammoth earth moving and mining equipment.

Gear Shaving | Article about Gear Shaving by The Free ...

The following article is from The Great Soviet Encyclopedia (1979). It might be outdated or ideologically biased. Gear Shaving a technique for generating improved tooth shape in gears of involute design. During the gearcutting process the initial standard contour of the pinion generating tool is displaced radially in such a way that the pitch line of ...

Grinding

Machines in our production Our CNC grinding machines for hollow, cylindrical and surface grinding ensures that we can comply with specifiions and measurements with great precision. Jungner TG .

Modern Gear

Modern Gear Machine is an ISO 9001:2015 registered company and we support a broad range of customers from global Original Equipment Manufacture's to local machine shops and the final enduser. I invite you to contact Modern Gear Machine today to discuss your manufacturing requirements or please send us a Request For Quote – we look ...

As one of the leading manufacturers of gear grinding ...

As one of the leading manufacturers of gear grinding machines, Burri has specialized in the production and new development of precision gear grinding machines, profiling machines and clamping systems and not only delivers high quality as standard, but is also a driver of innovation and progress in the machine tool sector.

REDIN PRODUCTION MACHINE

REDIN PRODUCTION MACHINE ... REQUEST A QUOTE | FAQS | VIDEOS | CONTACT US: GEAR DEBURRING MACHINES: BACK SPOTFACING: SPECIAL MACHINES: USED MACHINES: TRADEINS AND REBUILDS: SPARE PARTS: GRINDING WHEELS : Gear Deburring Machines : Model 600 : Model 1000: Model 2000: Model 3600 : Model 7200: Model 12 Horizontal : Model 10 retired ...

Gear Grinding Services

Welcome to the premier industrial source for Gear Grinding Services. The companies featured in the following listing offer a comprehensive range of Gear Grinding Services, as well as a variety of related products and services. provides numerous search tools, including loion, certifiion and keyword filters, to help you refine your results.

Okuma CNC Grinders | ID OD Grinding | CNC Machine Tools

Okuma and grinders reflect the design and precision of over 100 years of experience manufacturing grinders, now with the openarchitecture OSPP300G control. Our wide range of machines serves customers from high production manufacturers to job shops. Okuma is your only singlesource, top quality provider for grinders, controls, drives ...

Gear Grinding Market Size 2021 with a CAGR of %, Top ...

Global Gear Grinding Production by Region Global Gear Grinding Historic Production by Region () Global Gear Grinding Forecasted Production by .

Aerospace Gear Grinding Peekskill | AGMA Class 14 Gears ...

Gear Grinding At GMT, grinding both Internal and External Gears is one of our specialties. The modern equipment we utilize, such as our twin NILES ZE 400S machines, is second to none and capable of producing up to AGMA class 14 gears.

American Gear Manufacturers Association

Get into Gears is a campaign created by the AGMA Foundation to address the growing concerns over the lack of skilled employees in the gear industry. The campaign includes the free Employee Recruitment Toolkit with printed and web materials for companies to use to .

Gear Grinding Machine|Machine Tools|Products|Kanzaki ...

The compact machine forcused on automobile car allows shorter production line in small space. Simplified machine configuration offers acceptable machine price. ・7NC axis (FANUC 31 iB controller) ・Upright workpiece spindle. ・Wheel spindle comes with auto balancer, an AE sensor, rotary or gear dresser units. ・Dress methods: Rotary dresser.

G 250 Gear Grinding Machine

The result is an innovative, compact and extremely flexible gear grinding machine. The G 250 has been especially developed for very low cycle times and for topquality and efficient mass production of gears with outside diameters up to 250 mm and shafts with lengths up to 550 mm.

Production Grinding and Machining

Welcome. Established in 1997, Production Grinding and Machining is a steel welding and fabriion shop loed in Monroe, WI. We create custom benches, signs, and lawn and garden pieces. Let us know what you need and we will fabrie or repair your items (machinery, trailers, wagons, etc) to fit your needs. We can also create pieces for your ...

Latest Posts

- معدات التعدين واستخدام

- تطبيق موبايل محطم في الهند

- المطاحن الصينية

- سعر نقل الفحم لتوليد الطاقة الحرارية

- أغلقت مخروط محطم ملموسة

- محطم المبيعات الأولية

- تأجير كسارات أبردين

- الإمارات العربية المتحدة مصنع كسارات المحمول المختلفة

- بناء و تجهيز خط

- الدب الذهبي بالاهتزاز الطاعم للبيع

- استعراض شل طاحونة السكر

- تكساس ازتيك محطم أجزاء

- إيطالي التفاضلية الفك محطم

- يؤدي تأثير خنفساء

- تأثير محطم الحلقة

- Heavy Duty Jaw Crushers

- Operating A Quarry Plant

- Crushed Stone Prices Ireland

- Energy Saving Rod Mill

- Gold Processing Furnace

- Belt Grinder Germany

- 4500 Mesh Shale Mill

- Coal Mobile Crusher Provider In Angola

- Does A Clinker Grinding Mill

- Hot Selling Equipment Stone Jaw Crusher Products From China

- Raymond Mill S Ma Imum Capacity

- Manufacturing Plant Stone Crusher

- Sale Of Ball Mill

- New Design New Stone Crushing Plant For Sale In Costa Rica For Sale

- 200tph Crusher Washing