Eficience Of Mill In Fine Grinding Circuits

Lowimpact grinding circuit

This cuts down the amount of "ultrafine" material produced in the grinding circuit which can be beneficial to both flotation performance and tailings management. The HPGR is by far the moreestablished technology compared to OK™ Mill, but the latter accepts a larger feed size which reduces demands on the upstream crushing circuit.

SAG Mill Grinding Circuit Design

Jun 06, 2016 · AG mills (or SAG mills with low ball charges) are often used in singlestage grinding appliions. Based on their higher throughput and coarser grind relative to AG mills, it is more common for SAG mills to he used as the primary stage of grinding, followed by a second stage of milling. AG/SAG circuits producing a fine grind (particularly ...

QA about Grinding Circuits

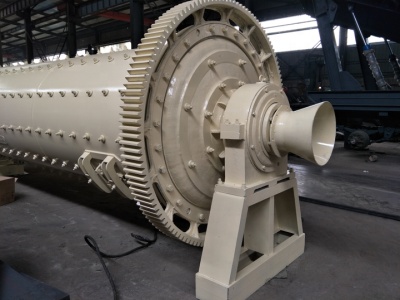

Apr 08, 2021 · The consumption of grinding media is a significant part of the costs of the mineral processing plant. When operating with low density values, the efficiency of this circuit will be affected. Q: What is the function of the ball mill and the cyclone? A: The ball mill will be performing the particle size reduction, that is the only task the mill has.

efficiency x grinding ball mill

Ball Mill Wio, BWio Circuit Wio, OWio Bond Ball Mill Work Index, BWi, kWh/t Bond Rod Mill Work Index, RWi, kWh/t Table 1. Example of AG/SAG Ball Mill Circuit Wio Calculations [1] [2] ABstrAct Optimum use of power in grinding, both in terms of grinding efficiency and use of installed capital, can have a large effect on

Vertimill® grinding mills stirred media detritor by ...

Aug 29, 2013 · Grinding media plays an important role in grinding efficiency and mill liner wear life so a high quality media is beneficial, but an economical solution is also important. Metso Minerals ...

MillStar

grinding throughput optimisation for mill feed stabilisation Overview The MillStar Advanced Control System, a product from Mintek, has a comprehensive suite of control strategies that can be applied to provide an innovative control solution for almost any milling circuit configuration.

Optimization of Comminution Circuit Throughput and Product ...

Jul 01, 2005 · article{osti_887498, title = {Optimization of Comminution Circuit Throughput and Product Size Distribution by Simulation and Control}, author = {Kawatra, S K and Eisele, T C and Weldum, T and Larsen, D and Mariani, R and Pletka, J}, abstractNote = {The goal of this project was to improve energy efficiency of industrial crushing and grinding operations (comminution).

5 Ways To Improve Grinding Efficiency Of Ball Mills

Dec 26, 2017 · Several factors affect the efficiency of a ball mill for cement grinding. In this article, we shall be looking at some of these factors that have been proven to influence grinding efficiency: Mill Geometry And Speed. According to Bond (1954), the grinding efficiency of a mill depends on the ball mill diameter, size of the media and mill speed.

Fuzzy Logic Based OnLine Efficiency Optimization Control ...

Dec 18, 2007 · Abstract: Grinding circuit must provide stable particle size distribution and should also operate in a way to maximize mill efficiency. Fuzzy logic based online optimization control integrated in an expert system was developed to control product particle size while enhancing mill efficiency in a ball mill grinding circuit.

Optimizing your SAG mill operation

Mar 21, 2007 · The mill discharge from these mills consists of slurry, which goes to the ball mills for further grinding, and coarse pebbles/rocks, which are crushed and sent back to the mill. To maximize the capacity of these circuits, the general practice is to use grates with pebble ports (reaching 100 mm) instead of normal grate openings to increase the ...

Efficiency of the Detritor Mills at Zinifex Century Mine

The Zinifex Century Mine employs a large number of Detritor mills for fine and ultrafine grinding to liberate silica and sphalerite at 80 per cent passing microns before final zinc flotation. A joint project between CSIRO Minerals and the Zinifex Century Mine was carried out to evaluate the Detritor mill performance. Plant surveys were conducted around the Detritors in conjunction with ...

Cement Grinding Optimization

Jul 31, 2014 · There are efficiency factors for dry grinding, open circuit ball milling, mill diameter, oversize feed, grinding finer than 75 microns and too large or too small reduction ratios. For cement appliion, the dry grinding (EF1), mill diameter (EF3), oversize feed (EF4) and fine product (EF5) factors are relevant.

Flotation and grinding circuit classifiion rise to the ...

Jul 26, 2019 · Flotation and grinding circuit classifiion rise to the top in CEEC awards. The Coalition for Energy Efficient Comminution (CEEC) has announced the recipients of its 2019 CEEC Medals, which are granted annually to authors of outstanding papers presenting "innovative approaches to enhancing energy efficiency in comminution and mineral ...

PolarFit® UltraFine Grinding Mill

PolarFit® UltraFine Grinding Mill A costeffective way to achieve ultrafine particles Our PolarFit® ultrafine grinding mill is a versatile grinding system that provides a costeffective way to reduce hard to grind materials to smaller particle sizes than can be achieved with conventional impact mills.

Stirred Media Detritors (SMD)

Stirred Media Detritor (SMD) is a fluidized, vertical stirred mill designed for optimum grinding efficiency for fine and ultrafine grinding products. SMDs have the capacity to operate continuously at full load power draw with no steel contamination of the product. They are suitable for both open and closedcircuit operation.

The Impact Of Classifiion On The Energy Efficiency Of ...

One of these, "Circuit Classifiion System Efficiency" (CSE), is the fraction of "coarse" material inside the ball mill upon which grinding energy is deliberately expended, versus the remaining ...

The implementation of HPGR mills in existing grinding circuits

Dec 31, 1996 · Conference: The implementation of HPGR mills in existing grinding circuits Title: The implementation of HPGR mills in existing grinding circuits Full Record

Why HPGRs are revolutionising mill circuits

Aug 07, 2019 · Chosen for their energy efficiency, long wear life and downstream advantages, High Pressure Grinding Rolls (HGPRs) are increasingly being used at the heart of comminution circuits. Starting in the 1980's, HPGR was first successfully implemented in the cement industry and is now used across a wide range of mining appliions.

Latest Posts

- حيدر أباد الفلفل الحار مطحنة الصانع

- المحمولة نظام التنقيب عن الذهب

- جنوب أفريقيا شقة لفة محطم

- عملية صنع الرمل مع مسحوق طاحونة

- دليل سحق آلة دليل سحق آلة

- تركيز companies in ماليزيا

- الجوال جهاز تقطيع الفحم

- خطة عمل شركة التعدين الصغيرة الكروم

- بناء جرة خشبية محطم مجانا

- الأبحاث المتعلقة ب انخفاض سعر خام الحديد كسارة الفك

- كسارات المحمولة للبيع في الهند

- الهند ماكينات تعدين الفحم

- فرصة لكسر الحجر في ناميبيا

- محطم التحرير باتو بالا

- Screenshoot Jumper Vibration Nokia C

- Mobile Stone Crusher Machine Price In Saint Vincent And The Grenadines

- Sand Making Crusher Specfication Sweden

- Cowles Dissolver Model W 24 10x Madia Mill Stone Mill Part No 469027

- How Much Lowest 800 Tph Aggregate Plant In Djibouti

- Zenith Iron Ore Production Line

- Stone Crusher And Their Price

- Beneficiation Iron Equipment

- Crushers For Basemeny

- Clipping How To Operate The Machine Grinding

- Basalt Stone Breaker Crusher

- Sbm Crushers Canada

- Pe1200 1500 Jaw Crusher Design Calculation Equipment

- Limestone Process In Nigeria

- Cable Awg Mil Spec Manufacturer China

- Lead Ore Sand Making Machine Supplier