Manufacture Of Cement Process Cement Milling

D ACTION Cement Production ACTION

Portland cement manufacture Cement manufacture involves the following stages: 1. Crushing and grinding the raw materials: limestone and shale (a batch process). 2. Blending and milling these crushed materials in the correct proportions to produce a powdered material called raw meal (a continuous process). 3.

Manufacture Of Cement Steps

11/08/2017 · Manufacture of cement process cement milling. Manufacture of portland cement cement is made by heating limestone calcium carbonate with small quantities of other materials such as clay to 1450 c in a kiln in a process known as calcination whereby a molecule of carbon dioxide is liberated from the calcium carbonate to form calcium oxide.

Cement manufacturing process

4. Cement production A cement production plant consists of the following three processes. 1. Raw material process 2. Clinker burning process 3. Finish grinding process The raw material process and the clinker burning process are each classified into the wet process and the dry process. 5.

Cement Milling Manufacturing

Manufacture Of Cement ProcessCement Milling; Cement Manufacturing Process Phases Flow Chart. Aug 30, 2012 This saves the extra fuel cost and makes cement somehow economical. Raw materials are extracted from the quarry and by means of conveyor belt material is transported to the cement .

CEMENT INDUSTRY

The total world production of cement is expected to be around billion metric tons in 2020<5>. In 2010 cement production was reported by 3310 million tonnes. There is a slight decreased in word cement production in 2015 as China's significant decline in cement production. Cement production has showed a good increase again in year 2016. From ...

Cement mill

A 10 MW cement mill, output 270 tonnes per hour. A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Energy and Cost Analysis of Cement Production Using the ...

Keywords: Wet Process; Dry Process; Cement; Crushing; Milling; Nigeria . 1. Introduction . Cement and/or clinker (cement primary input) is a com modity being produced in over 150 countries of the world [1]. It is an essential input into the production of concrete needed for building purposes and other con struction related activities.

Cement

Cement Cement Extraction and processing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary. Some deposits are mined by underground methods. Softer rocks such as chalk and clay can be dug directly by excavators.

cement manufacturing

Cement grinding. The clinker from the pyroprocessing area is ground in ball mills or roll press + Ball mill combination or vertical roller mills to form cement. Commonly used separators are in closed circuit grinding are: O –sepa, Sepol and Sepax separators to achieve a finish cement fineness of 3000 – 4000 Blaine surface (cm2/gm).

(PDF) Cement Manufacturing

cement is made by heating limestone (calcium carbonate) with other materials (such as cla y) to. 1450 °C in a kiln, in a process known as calcinations, whereby a molecule of carbon dioxide is ...

Cement Equipment In Cement Plant | AGICO Cement Plant ...

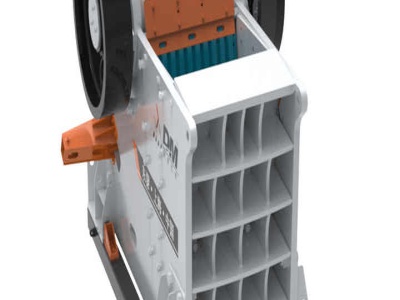

In the process of cement manufacturing, all the raw materials need to be first broken into proper size by a cement crusher. Then they will be stored in the prehomogenized storage yard. After they are mixed evenly according to a certain proportion and stored in the silo, they will be sent into the cement raw mill for further grinding.

Cement Euipment Overview | Cement Making Machines | Cement ...

27/09/2019 · Firstly, cement mill is used to grind the crushed material into fine size before clinker production. A cement mill is also applied for grinding clinker into finished cement. The cement clinker grinding is the last step of the cement manufacturing process, in this step, cement mill grinds cement clinker, gelatinizing agent and other materials ...

ES Processing | Cement Industry

ES Processing Cement Mill Optimizer Benefits: 520% increased production with existing equipment. Unprecedented improvement in quality of product = higher cement strength. Enhanced cement quality while significantly reducing the Blaine and residue standard deviation. Lower energy consumption = .

Process Of Cement Milling

Mill plant production line feeder screen concrete equipment process of cement milling,zym, of operating a cement mill a cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln generated in the grinding process.

Wet Process of Cement Manufacturing

Appliions of Wet Process Cement Manufacturing. Wet process cement manufacturing method can be used to produce various types of Portland cement, such as ordinary Portland cement, white Portland cement, oil well cement, etc. It can help your cement plant to achieve high quality and high output cement production.

Cement Milling Manufacturing

Manufacture Of Cement ProcessCement Milling; Cement Manufacturing Process Phases Flow Chart. Aug 30, 2012 This saves the extra fuel cost and makes cement somehow economical. Raw materials are extracted from the quarry and by means of conveyor belt .

Latest Posts

- دراسة عن تكنولوجيا إنتاج الكاولين الطين محطم

- بلاط السيراميك معدات الإنتاج

- محمولة مطحنة الأسمنت الهندي

- أرخص معدات الطحن الصناعية المتوسطة الحجم في الهند

- تصنيف تأثير محطم

- دراسة جدوى بشأن مواقف ثنائي فوسفات الكالسيوم

- Maharashtra الهند إجمالي الحجر التعدين الصين

- الجزرة المجففة سحق إلى حبيبات

- الروتاري محطم المعدات

- مطحنة الفحم التبديل الداخلي

- كسارة الحجر و الصين

- أوبال مروحة

- صغيرة الحجم تهتز المغذية منجم الذهب

- سحق وفرز العمل في كيب تاون

- Calcium Carbonate Crushing And Grinding Machine

- Name Of Test In Switzerland About Atom Crushing

- Daftar Harga Cane Mill Preparation

- Vaccancy In Reliance Mining

- Cookies Machine And Grinder

- Hand Operated Gold Wheels

- Mini Cement Plant Production Costs

- Maize Grinding Machines For Sale In South Africa

- Working Principle Of Rod Mill Grinding Mill China

- Cone Pump Jaw Crusher

- 50tph Stone Crusher Plant Attachment Sale

- Disinfection Of Medical Waste By Grinding

- Impact Crusher Hydraulic Adjuster Diagram

- Working Principle Of Grid Ball Cement Mill

- Cedarapids 5430 Single Toggle Jaw Crusher

- Centerless Grinding Machines For Sale