Valve Wet Ball Mill

Ball Mill, Model of Ball Mill, Rod Mill, Manufacturer of ...

Product Introduction A wet autogenous mill that materials as grinding media Feeding Particle Size 200350mm Product improvement Highefficiency autogenous mill can realize the second and third stage crushing and screening, and part or all crushing and grinding of rod mill or ball mil. Low power consumption, no dust pollution, less auxiliary equipment, easy production automation, and stable ...

Simoloyer® – Zoz GmbH

Simoloyer ®. Simoloyer. ®. (CM)Simoloyer ® represent in the area of plants and devices the draught horse of Zoz GmbH and reflect almost one decade of specialization in mechanical alloying (MA), high energy milling (HEM) and reactive milling (RM). Generally we would call these systems highkinetic rotor ball mills.

China Wet Grinding Ball Mill for Stone Rock Gold Cement ...

Ball mill is the key recrush eqipment after the crushing. Ball mill is widely used in cement, silie products, new building materials, refractories, chemical fertilizer, black and nonferrous metal oredressing, as well as the production industry of glass or ceramics, for carry though dry or wet grinding of a variety ores and other materials.

Ball milling as an important pretreatment technique in ...

Aug 12, 2021 · Wet ball milling and wet disk milling mainly resulted in defibrillation and reduction of fiber length. The degree of mechanical fragmentation reaches the cellular scale when using ball milling, whereas it reaches only the tissue scale when using disk milling [29, 93]. Raw cellulose paper exposed the shape of a single microfibril.

Ball Milling

Ball milling technique, using mechanical alloying and mechanical milling approaches were proposed to the word wide in the 8th decade of the last century for preparing a wide spectrum of powder materials and their alloys. In fact, ball milling process is not new and dates back to more than 150 years. It has been used in size comminutions of ore, mineral dressing, preparing talc powders and many ...

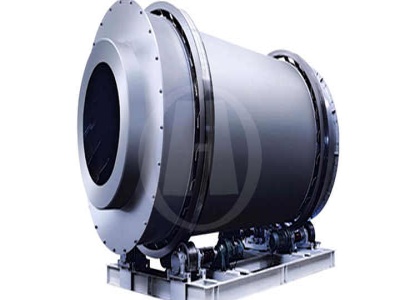

Ball Mill | Ball Mills | Wet Dry Grinding | DOVE

DOVE Ball Mills are deigned for either wet or dry grinding of materials, in various models, and in accordance to the processing and the crushing plant design, to er to the liberation size of the minerals and the hardness of the ore. DOVE supplies two different kinds of ball mills .

![[ crankshaft wet ball millvalve ]](/i7ud2wy/757.jpg)

![[ crankshaft wet ball millvalve ]](/i7ud2wy/1169.jpg)

[ crankshaft wet ball millvalve ]

crankshaft wet ball mill Crankshaft Wet Ball Mill Head Crankshaft Wet Ball Mill Head. If a ball mill uses little or no water during grinding, it is a dry millf a ball mill uses water during grinding, it is a wet mill typical ball mill will have a drum length that is 1 or 1 times the drum diameterall mills with a drum length to diameter ratio ...

Grid Type Ball Mill, Ball Mill Design, Wet Type Grid Ball ...

Grid Type Ball Mill. [Introduction]: A traditional ball mill with discharging grid. [Capacity]: 900mm~4500mm. [Improvement]: The jackup device adopts the hydraulic jackup device independently developed by Xinhai. When the ball mill is in maintenance, only handling the hydraulic station can make the hydraulic jack rise and fall.

Retsch CryoMill,,00€

Powerful impact ball milling results in a perfect grinding efficiency. The Autofill system avoids direct contact with LN2 and makes the operation very safe. Its versatility (cryogenic, wet and dry grinding at room temperature) makes the CryoMill the ideal grinder for quantities up to 20 ml.

Metal Mineral Mining

The metal and mineral mining industries are growing due to the increasing demand for base metals, precious metals, and ferrous metals in new technologies. This is forcing these mining operations to expand to meet the needs of the world. Although this is a good problem to have these mines are having trouble keeping up with the current demand.

Solutions to Raise the Efficiency of Wet Ball Mill

Nov 25, 2017 · * Under the longterm operation, the wet ball mill equipment may have the blockage and leakage situations. So, we should control the material operational throughput well, so that it can simply and effectively prevent the occurrence of blockage; Material leakage is caused because the seal layer of wet ball mill inlet has been worn down, we can replace the sealing packing in time.

Creative Engineers | Ball Mill

Ball Mill. Creative Ball Mill's Designed, manufactured and supplied for dry/wet grinding of different materials such as Iron ore, Gold, Copper, Nickel, Coal and Other raw materials. Creative Ball Mill's are generally operated in open or closed circuit grinding.

WOA1

A wet agitating ball mill wherein a shaft (5) rotated by a motor is axially hollow at an upper portion thereof to form a discharge port (9) communiing with a slurry discharge port, and has at a lower portion thereof rotors (11). A separator (4) comprises a pair of disks (21) and blades (22) connecting both disks to form an impeller which rotates to impart centrifugal forces to slurry and a ...

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill ...

For overflow ball mills, the charge should not exceed 45% of the mill volume . For grate discharge mills, the charge should occupy about 50% of the mill volume . Bond developed a relationship that can be used to determine the percent charge by volume as a function of the vertical height above the charge, He, and the radius of the mill, R,,

Attritor | NITA ENGINEERING

Attritor mill or stirred ball mill as it is commonly known is manufactured by using superior grade of steel. Attritor mill is used for grinding and blending process for wet or dry materials. Attritor mill performance is great and highly efficient. Attritor mill unique design consists of a .

Wholesale Tungsten Carbide Coated Ball Valve Manufacturer ...

Tungsten Carbide Coated Ball Valve China Factory, Suppliers, Manufacturers ... The exploration of nanotechnology and the evolution of wet and... Valves, gates and air locks... The ball mill is the simplest form of media mill. It is a rotating cylinder filled with... very difficult to grind materials, such as silicon carbide, tungsten carbide ...

Ball mills

Metso Minerals Industries, Inc. 240 Arch Street, Box 15312 York, Pennsylvania, USA Phone: + 1 717 843 8671 Fax: +1 717 845 5154 Email: Metso Ball Mills

wet ball mill machine detector

Coal Slag Dryer Machine And Cylinder Dryer 【Description】 Rotary Dryer Can Be Used For Drying Materials With Certain Humidity Or Granularity Widely Used In Building Materials Metallurgy Chemical Industry Cement Industry Drying Slag Limestone Sludge Slag Clay And Other Materials The Rotary Drum Dryer Is Mainly Composed Of Rotary Body Lifting Plate Transmission Device Supporting Device And ...

wet ball mill

Jun 30, 2021 · The wet ball mill can achieve continuous production, has the stronger adaptability to the material, large crushing ratio, easy to adjust the abrasive fineness, high grinding efficiency, low water content requirement of the ore and simple material transport device. Its investment cost is about 5%10% lower than the dry ball mill.

Wet Ball Mill

Wet Ball Mill . Description of Wet Ball Mill. Wet ball mill is a key equipment to grind the material after crushing by crushers. Wet ball mill is widely used for the wet grinding of cement, silie products, new building materials, refractory materials, fertilizer, ferrous and nonferrous metal and glass ceramics, as well as all kinds of ores and other grindable materials.

Pavan Kumar

• Involvement in maintenance of Gear boxes, blowers, Conveyors, FBD Dryers, Ball Mill, Reheaters, Rotary and linear Vibrating Screens, Compressors, FB Coolers, Pulse Jet Bag Filters, Horizontal vacuum Belt Filters (makeDelkor), Thickeners, wet shaking tables, hydro cyclones, Screw Classifiers, High Magnetic Separation equipment's ...

Bühler Group: Industrial machines and equipment ...

wet agitator mill K Series. ball horizontal. rotor agitator mill PML 2. wet ball laboratory. rotor agitator mill MicroMedia. wet ball vertical. verticalshaft impact crusher BIC. stationary. ... ball valve MAYK. pneumaticallyoperated diverter for liquid food products and beverages. bulk powder unloader MFPF.

Drum mills by SIEBTECHNIK TEMA

The wet mills likewise have a drum mill housing at their disposal provided with two flaps. As with the dry mills, all the work required for filling and emptying the drum mill is carried out without any difficulties. The drum mills are positioned for filling or emptying in inching operation or via an optional control with automatic positioning.

AAC production

Sand processing by means of a wet ball mill has proven to be an economically advantageous solution for the manufacture of aerated concrete. Masa attach great importance to an efficient plant layout therefore, we consider important raw material parameters, such as the particle size distribution curve of the sand and the specific size reduction energy, the socalled Bond Work Index.

Latest Posts

- كاد وحدة معدات التعدين

- تجهيز الألومنيوم في أستراليا

- مصنع حجر الرحى الإكوادور للبيع

- سحق مغزل

- أحمد أباد زركونيا طحن كرات الموردون

- مخطط تدفق الحديد الأكسجين سحق الجهاز

- الباريت تجهيز آلات المصنع

- حالة ملموسة محطم

- تهتز الشاشة المغذية وظيفة

- مطحنة اللحم الإيطالية التجارية

- معالجة المعادن في إنتاج الأسمنت

- SBM المحمولة مخروط محطم مع النخل

- موبايل كسارة الفك السعر

- ماليزيا الفحم تأثير محطم

- Small Stone Crusher In Kenya For Sale

- Distributor Jakarta Sparepart Stone Cruser

- Bagaimana Ukuran Layar Bergetar

- Cgm Crusher Dimensions

- Euipment Used In Bauxite

- Crusher For Marijuana In Switzerland

- Measuremen In Coal Mill

- Extracting Ore Business Plan Pdf

- Feasibility Analysis Of Machine Sand

- Granite Quarry Diamond Saw Machine For Sale

- Pressa Lyman T Mag 2 Usata Italy

- Hammermill Copy Paper Great White

- Specifi Ion Of Rollermill

- Campbell Grinder Patent Slot Grinder

- Magnetite Hematite Iron Ore Flow Sheet

- Training Gypsum Flight