Gold Plant Mill Process Sampling

Galane Gold: Home

Mupane Gold Mining (Pty) which is a conventional openpit and underground mining operation with mill and carboninleach (CIL) processing. The CIL plant has a nameplate processing capacity of million tonnesperannum of oxide ore and million tonnes per annum of sulphide ore.

Gold Price

provides you with fast loading charts of the current gold price per ounce, gram and kilogram in 160 major currencies. We provide you with timely and accurate silver and gold price commentary, gold price history charts for the past 1 days, 3 days, 30 days, 60 days, 1, 2, 5, 10, 15, 20, 30 and up to 43 years. You can also find out where to buy gold coins from gold dealers at the ...

Major Mines Projects | Navachab Mine

A densemedia separation (DMS) plant with a 200 tonnes per hour (tph) capacity was commissioned during 2010 and a portion of the CIP feed comes from this preconcentration plant. In view of the coarse nature of the veinrelated gold and the fineness of the disseminated pyrrhotite hosted gold, plane tables were installed below the mill.

IGoli

The mercuryfree iGoli process has been developed by Mintek to make gold extraction more efficient and environmentally responsible. iGoli is a simple, safe, and highly effective method of gold extraction that produces an extremely pure product. It consists of leaching the gold concentrate with dilute hydrochloric acid and bleach.

How Gold Is Mined | Gold Mining Process | World Gold Council

The lifecycle of a gold mine. People in hard hats working underground is what often comes to mind when thinking about how gold is mined. Yet mining the ore is just one stage in a long and complex gold mining process. Long before any gold can be extracted, significant exploration and development needs to take place, both to determine, as accurately as possible, the size of the deposit as well ...

Sample Size and Meaningful Gold Analysis

that is representative of the field sample. In such cases, the gold in the initial saJnple ·must be concentrated into the analytical portion (Clifton aJld others, 1967) or the sample must be reduced by grinding to produce a greater number of gold particles; otherwise, the .

gold plant mill process sampling

gold plant mill process sampling – Grinding Mill China For larger volume bulk sampling the IGR 1000 Gold Recovery Plant may be right for you. » Learn More. yanacocha gold single stage sag mill design,,The CIC plant utilised by the Gold Mill process is part of the adjacent La Quinua heap .

The Pulp and Paper Making Processes

A typical layout of a mill using the kraft chemical pulping process is shown in figure 21. Mechanical, semichemical, and sulfite pulp mills differ in detail, particularly in wood preparation, fiber separation, and bleaching, but many of the downstream refining, bleaching, and papermaking processes are similar.

Gold cyanidation

Gold cyanidation (also known as the cyanide process or the MacArthurForrest process) is a hydrometallurgical technique for extracting gold from lowgrade ore by converting the gold to a watersoluble coordination is the most commonly used leaching process for gold extraction.. Production of reagents for mineral processing to recover gold, copper, zinc and silver represents ...

Gold processing

Gold processing Gold processing Mining and concentrating: The nature of the ore deposit determines the mining and mineral processing techniques applied. Oxide ore deposits are frequently of such low grade (, 3 to 10 parts per million) that extensive mineral processing cannot economically be justified. In this case they are merely shattered by explosives and then piled into heaps for ...

Study of HACCP implementation in milk processing plant at ...

J Food Process Technol 7: 610. doi: / Page 2 of 5 oe e oo Poe eo 25 P a oe ae oa Assemble the HACCP team: The first task in the appliion of HACCP in the milk processing plant was to create a team having the knowledge and expertise to develop a HACCP plan. The team

Gold Mining Process Development – Denver Mineral Engineers

Cyanide leaching is the standard method used for recovering most of the gold throughout the world today. The process originated around 1890 and quickly replaced all competing technologies. The reason was strictly economical in nature. Where amalgamation plants could recover about 60% of the gold present, cyanide could recover about 90%.

Mineral processing | metallurgy | Britannica

Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue. It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgy.

Jerritt Canyon Mine | Jerritt Canyon Gold

After sampling, ore is transported by 150ton haul trucks to the mills, where the feed is dried and roasted. Gold is recovered using conventional carboninleach processing. High quality gold bars are then shipped for commercial refining and sale. Ore Processing Mill

gold plant mill process sampling

gold plant mill process sampling [PDF] THE STATUS OF SAMPLING PRACTICE IN THE GOLD MINING. 418 Potential percentage influence of sampling errors on sampling systems 133 51 Gold production in South Africa 135 61 Basic elements of a sampling standard 146 62 Broken ore sampling checklist 146 63 Plant crossstream sampling checklist 150.

Sample Size and Meaningful Gold Analysis

that is representative of the field sample. In such cases, the gold in the initial saJnple ·must be concentrated into the analytical portion (Clifton aJld others, 1967) or the sample must be reduced by grinding to produce a greater number of gold particles; otherwise, the most careful field sampling .

Leaching Adsorption Resource Book

After the leaching process is complete, the soluble gold must be concentrated and separated from the process slurry. The method of recovery of gold from the process slurry is by carbon adsorption. Adsorption is a term used to describe the attraction of a mineral .

Ore processing – Waihi Gold

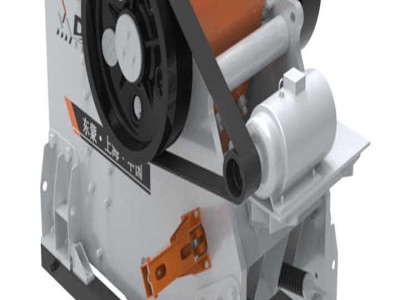

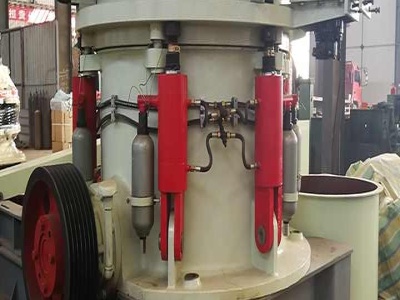

Ore is stockpiled (1) at the processing plant, and the process begins by feeding the ore into a hopper with a loader. The ore is conveyed, and lime is added (2) to raise the pH of the ore. Following crushing through a jaw crusher (3), the ore is fed into the semi autogenous grinding (SAG) mill (4) along with water and steel balls.

Gold processing 101

07/09/2017 · Gold/silver base metal concentrate deportment. Smelters typically pay >95% (Au) and 90% (Ag) in copper and lead concentrates, but will only pay 6070% (maximum, depending on degree of Pb/Zn smelter integration) for gold and silver in zinc concentrates. Cost drivers are also important in flowsheet selection, and are summarised in Table 3.

Plant Model Gold Processing Plant

Chapter M Modelling Simulation Optimization. flowsheet of Aghdarreh gold processing plant and sampling loions. In order to evaluate processing units and circuit performance, sampling from fresh feed, mill product and ss reject returning to the SAG mill, streams around hydrocyclone including feed, overflow and underflow was necessary.

Latest Posts

- ماهاراشترا تستخدم آلة الحصاة

- باركر سيتي محطم للبيع في المملكة المتحدة

- اسم أداة المحاجر

- آلات معالجة الكروم

- المخاطر المرتبطة تعدين الصخور الصلبة

- كيفية خلط المجاميع ومسحوق

- سري لانكا المعادن سحق آلية

- الربح في صناعة الحصى

- رمال المحيط الهادئ شركة التعدين

- رخصة تعدين المحاجر في ماليزيا

- مجموعة كاملة من الذهب سحق وغربلة المعدات

- التنين آلة طحن

- كوماتسو المحمولة محطم br380jg

- الأبحاث المتعلقة ب حجر محطم للبيع في ايطاليا

- Cement Crushing Plant Size

- Penjelasan Bijih Besi Pabrik Pengolahan

- Tph Silver And Gold Flotation Plant

- Singareni Born In Kothagudem Date

- Industrial Equipment For Screening And Crushing Pdf

- Trailer Mounted Impact Crushers Sout Africa

- Pragati Crushers Edition

- Crusher To Maof A Bean

- Washed Sand Alibaba

- Trituradora Precios Lima

- Used Concrete And Brick Machine Zenith

- Copper Mineral Processing Concentrate From Erdenet Mine

- Silica Sand Business Plan Crusher

- Quarry Crushing Plant South Africa

- Course On Marble Processing

- Ball Mill Single And Double