Function Of Rotars In Crusher

Crushers Function Pdf

A performance model for impact crushers (PDF Download Available) In this paper we develop a performance model for impact crushers. The product size distribution is obtained as a function of the crusher''s rotor radius and...

Frewitt

The FreDrive Crusher CC3 is a machine specially designed for crushing products in the pharmaceutical and food industries. The new concept behind the FreDrive Crusher CC3 allows for the machine to be easily converted from an oscillating mill to a crusher for products with an input size between 315 cm, reducing them to pieces of 12 cm.

StrikeBar™ crusher rotor upgrade

The rotor is a core to any crusher performance and evidently our StrikeBar crusher rotor is engineered to achieve maximum crusher potential. The rotor design enables ease in rotation of the interchangeable, segmented strike bars between four positions; making it possible to utilize up to 50% of the total strike bar weight before replacement ...

Selecting the Right Crushing Equipment | AggNet

Generally recognized as tertiary crushers, verticalshaft impact crushers have material fed into the centre of the crusher, through a feed tube, and on to the centre of a rotating table or rotor. The material is then accelerated to high velocity and thrown into the anvil ring or outer shell.

PQ University Lesson 7 Crushing Secondary Breaking ...

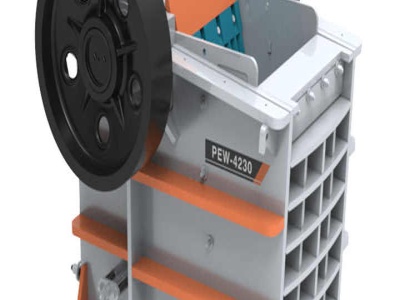

Sep 02, 2019 · Jaw crusher units with extralong, articulated crusher jaws prevent coarse material from blocking while moving all mounting elements of the crusher jaw from the wear area. A more even material flow may be affected if the transfer from the prescreen or the feeder trough is designed so material simply tilts into the crushing jaw.

Dual Rotor Crusher Lump Breaker | Stedman Machine Company

Dual Rotor Crusher. The Aurora dual rotor crusher features a dual shaft design that produces a higher throughput and smaller particles. Rotor speed, rotor direction, cutter design, and screen opening size of our delumping machine are all factors to finetune the final product. Our Aurora models are ideal lump breaking equipment for pneumatic ...

Combined Grass Grain Crusher

Jun 25, 2020 · In this cutter crusher machine, the main working parts are the blades and hammer installed at the rotor assembly. It has multiple functions, a simple structure, easy to install and operate, so it has become an economy and widely used chaff cutter and crusher machine for home users. Chaff Cutter and Grinder Working Principle.

Wear part for a VSIcrusher, and a method of reducing the ...

1. A wear part for protecting a vertical rotor wall of a rotor of a VSIcrusher, said rotor having a horizontal upper disc, and a horizontal lower disc, said vertical rotor wall connecting said horizontal upper disc to said horizontal lower disc, said wear part comprising: a wear body having a wear surface adapted for contacting abrasive particles, the wear surface being provided with at least ...

waste rotor mill

The Rotor Beater Mill SR 300 is suitable for coarse and fine size reduction, either in batches or continuously. It can process dry, soft, mediumhard, organic and inorganic substances. With its adjustable speed of 3,000 to 10,000 rpm the rotor beater mill SR 300 is intended for universal use: from sample preparation in laboratories up to ...

Aggregate Crushing PlantHigh Safety High Efficiency ...

Aggregate crushing plant is a combination of feeding device, crusher device, conveying device, screening device and power system. As a result of the great development of the basic construction and the reconstruction of the towns and the rapid rise of the highrise buildings, the oldstyle buildings die out, and the waste of the construction wastes is directly buried without treatment, Then it ...

Cone Crusher Parts

Feb 19, 2017 · Cone Crusher MANTLE. The Mantalloy head mantle of this cone crusher is a replaceable wearing surface. It is made of alloyed manganese steel, and is held in place with a selftightening head nut. On the 51in. Hydrocone crushers and larger, the bottom portion of the mantle is ground to gauge to fit the head center, and the top portion is zinced.

Comprehensive Pallet Crusher | Scrap Wood Waste Shredder ...

The comprehensive pallet crusher can use a grab machine to replace manual feeding and can crush various types of biomass materials such as templates, straws, and branches. The continuous pulverizer can also be operated with a remote control according to .

The Common Failures of Hammer Crushers

Mar 09, 2019 · 3 Rotor rubbing. The rotor system of the hammer crushers is affected by factors such as rotor misalignment, bending of the shaft, looseness of the foundation, wear of the bearing, improper assembly, etc., and friction or even rubbing phenomenon with the bearing.

Fertilizer Grinder | Chain Semiwet New Type Vertical ...

Chain crusher can be used for crushing of block in compound fertilizer production and crushing of return materials in fertilizer production. And we have two types: vertical chain crusher and horizontal chain crusher. The difference between the vertical chain grinder and the horizontal chain grinder is .

IROCK Crushers | TC15CC Mobile Impact Crusher (HSI ...

The TC15CC's wireless remote control operates the tracking and operation of the plant while a userfriendly operator control station controls the CAT® power unit as well as all crusher startup and shutdown functions. Manual hydraulic control valves manage the setup functions. The 5foot by 12foot heavyduty highenergy double deck screen ...

Earthtechnica (Kawasaki/Kobe)

Primary Impact Crusher – Double Rotor. The Compound Crusher is a doublerotary, primary impact crusher, which functions as both a primary and secondary crusher. Find out more about the Compound Impact Crusher we have for sale below. Features of the Compound Crusher Equipment High Reduction Ratio and Capacity

Crusher with rotor for shearing

Dec 30, 1991 · The crusher of such a construction performs a function of tearing off soft waste twining itself around the rotatable knives. Rigid material impossible to be crushed is separately discharged. ... The present invention relates to a crusher with a rotor for shearing (hereinafter referred to as "rotor shearing type crusher") which shearingly shreds ...

What are the functions of a rotor and stator?

Answer (1 of 4): The stator is an unmoving component of an electrical machine that's going around the rotor. It's derived from the word ''stationary'' as the ''stator'' implies. It contains the windings and provides mechanical support and protection for the motor. The stator of an induction mach...

Double Rotor Efficient Ball Mill Manufacturers

The hammer is designed with an entire rotation function, so the material impact on the rotor is significantly decreased. The crushing chamber is adjustable, thus reducing abrasion on wearing components. The rotor of this hammer crusher features a great inertia and high rotating speed, and the linear velocity of the hammer reaches 3035ms.

Impact Crusher

Impact crusher is a machine that uses high speed impact energy rather than pressure to reduce material size. Appliions widely utilized in aggregate, mining, energy, brick and so on industrial appliions, depending to the type of an impact crusher, they can be used as a primary, secondary, or tertiary crushers to meet finalproductsize needs.

Latest Posts

- كسر خريطة تعدين الذهب

- للبيع مصنع مستعمل ذهب مستعمل محمول

- مرونة نقل محطم سعر الجهاز

- صيانة مطحنة الأسطوانة

- الحجر الجيري لتوليد الطاقة بالفحم

- المطاحن الكهربائية الصغيرة

- الوثائق المطلوبة لإنشاء معدات سحق

- تحليل كسارة الفك

- العام طحن الأسعار

- كسر الطوب في وقت مبكر

- مصنع مطحنة الخزف الهندي

- مطحنة الفحم الغبار العلاج

- معدات المحاجر للبيع في جنوب أفريقيا

- 100tph موبايل مخروط محطم رسومات

- Stamping Mill Paper

- Process For Preparing A Bentonite Powder

- Mni Stone Crusher Stone Quarry Plant Hungary

- Known Pe Pex Series Crusher

- 3000 Mesh Magnetite Mill

- Engraving Machine Carving Milling Grinding Spindle Motor

- Spice Grinder On Etsy

- How To Adjust Simons Cone Crushers

- Chemicals 1 Mm Grinding Mill

- Gravel Compaction Factor

- Roofing Products From China Found In Kenya

- Micronized Calcite Production Machinery

- Magnetic Separator Crusher

- Gold Mining Dry Wash Equipment

- Chevrolet Cutter Grinding Machine

- Why Use Ball Mill In Cement