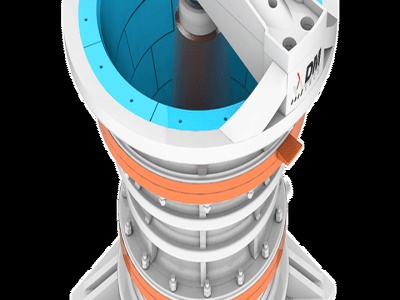

Raw Materials Ball Mill

Górka Cement

Calcium aluminate cements ( GÓRKAL 40, GÓRKAL50+) are made from two materials: bauxite and high alumina cements ( GÓRKAL 70, GÓRKAL 80) bauxite is replaced with the process of production, premixed raw materials are ground, and the slurry obtained is collected in on the desired type of cement, we make corrections to the premix to obtain an ...

Pulverising mill for raw materials | InterCem

May 02, 2019 · The raw mill, which has a diameter of m and a length of m, features a drying chamber that extends it by another 3 m. The ball mill has a central drive with an output of 3500 kW. Intercem provided all the engineering work, documentation, construction supervision and commissioning.

What are the Different Types of Ball Mills?

Depending upon the type of raw material used by an industry, its equipment is chosen from a range of tools available in the market. Likewise, the shape and orientation of ball mills are decided by considering the equipment, which it is expected to supplement. Horizontal Ball Mill: The most common type of product supplied by ball mill manufacturers of India is the horizontal ball mill. As the ...

Raw Material

The raw materials are further processed and ground. The grinding differs with the pyroprocessing process used. The raw materials are prepared for clinker production into a 'raw meal' by either dry or wet processing. In dry processing, the materials are ground into a flowable powder in ball mills or in roller mills.

Ball Mill For Raw Material

Ball Mill For Sale Grinding Mill For Raw Material. PROJECT CASE. Hmard Machinery is a professional material processing designer and supplier in the world, we have excellent research and development group to provide our clients the optimized material processing can provide our customers the allsided produce project such as aggregate production line, mineral ore processing plant ...

The design and optimization process of ball mill to reduce ...

· The raw materials were ground from the big particle size to the smallest possible by using multistep grinding. In the laboratory, the common method to be used as the ball mill. This work aims to design a simple horizontal ball mill. Calcium carbonate material from limestone and eggshells powder was ground using the developed ball mill. The ...

Ball MillChina Ball Mill Manufacturers Suppliers | Made ...

Ball Mill for Grinding to Stone Powders Wet / Dry Grinding Ball Mill. US 6,000120,000 / set FOB. MOQ: 1 set. Since 2016. Main Products. Jaw Crusher, Ball Mill, Shaking Table, Feeding Equipment, Classifing Equipment, Flotation Equipment, Magnetic Separator, Conveyor, Drying Equipment, Gravity Separation Equipment.

Visual Encyclopedia of Chemical Engineering

Raw materials undergo size reduction through different mechanisms: impact, compression, and attrition. ... Types of tumbling mills include rod mills, ball mills, and tube mills. Pronounced preferential breakage of the coarser particles is responsible for the "screening effects" that occur in rod mills.

raw material ball mill

Raw Material Ball Mill. Raw Material Vertical Roller Mill Great Wall Corporation According to the display of material production measured data it can be saving electricity above 30% use of vertical roller mill production per ton raw material than traditional ball mill and power saving effect is very remarkable 3

Effect of Different Raw Material Property for the ...

Effect of Different Raw Material Property for the Fabriion on Al/CNT Nanocomposite Using a Ball Mill with a Discrete Element Method (DEM) Simulation Materials (Basel) . 2019 Oct 10;12(20):3291. doi: /ma.

Baltec

These ball materials are often used because they are inexpensive. Nylon is one of the most common plastic ball materials. It is hard, it is tough and it is dense enough so that it sinks in water. Nylon is slightly hygroscopic, so it isn't the best plastic to be used in water appliions. PTFE. is a fairly common plastic ball material.

Ball Mill for Raw or Cement Material Grinding Property of ...

Ball mill for raw or cement material grinding. School Harvard University; Course Title DUNK 100; Uploaded By allminds62. Pages 37 This preview shows page 17 19 out of 37 pages. Study on the go. Download the iOS Download the Android app Ball Mill for Raw or Cement Material Grinding ...

ball mill operation in cement raw material grinding

Raw Material Ball Mill. 202157 · This ball mill is mainly used for grinding raw materials and final products in cement plant. It can be replaced by vertical raw mill. It is also suitable for grinding various ores and other materials in the metallurgy mine chemical construction and other industries. Chat Online ; Raw mills for all requirements Gebr. Pfeiffer. Grinding of cement raw ...

Raw Materials Powder Making Ball Grinding Mill Machine ...

Ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silie, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds of ores and other grindable materials.

PHARMACEUTICAL TECHNOLOGY 1: EXPERIMENT : BALL .

Dec 11, 2014 · In choosing the right equipment for size reduction process, one of the factor influences is the nature of the raw materials. Most of the raw material must be dried before undergo the reduction process. ... As the aim of this experiment is to study the effect of the various parameters on the performance of a ball mill. The factors studied are ...

Raw Materials – Sherline Products

Your local scrap dealer is a possible source for raw materials. This rack at a metal dealer in Escondido, CA, is neater and better organized than many. Some materials are colorcoded, but codes can vary from company to company, so it can be hard to be sure exactly what you are getting unless the mill's grade markings are still on the pieces.

Preparation Of Cement Raw Material | Cement Mill, Cement ...

Grinding: grinding all materials into required fineness by cement mill. Cement ball mill and vertical cement mill are two common types. Homogenizing: homogeneous kiln feed is the precondition of clinker production, so homogenization of raw materials guard a pass of cement plant.

Ball Mill For Iron Raw Material

Raw material ball mill suppliers and raw material ball nameraw material used for making ceramic 68 alumina ball for ball mill featurehigh strength high hardness high wear resistance high specific gravity small volume high temperature corrosion resistance no pollution and other excellent properties,professional raw material ball mill in nigeria.

Ball milling as a mechanochemical technology for ...

· As illustrated in Fig. 2, the balls and raw materials and reagents are mixed together, while the jars spin in a specific direction, resulting in the impact or pulling forces to the materials (Howard et al., 2018). Each type of mill is designed with a specific purpose. Speed, time, substrate loading, and geometric parameters of the mill are ...

Raw Material Ball Mill,

Raw Material Ball Mill sinounique. The raw material ball mill is key equipment for the grinding process of the raw material after the crushing process of it It is widely used in the cement silie product industry, new type construction material industry, refractory matter industry and glass ceramic industry for grinding various minerals and materials After long term experience of design and ...

The operating principle of the ball mill

Feb 08, 2017 · The operating principle of the ball mill consists of following steps. In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media. The material grinding occurs during impact falling grinding balls and abrasion the particles between the balls. Then, discharge of ground material performed ...

Latest Posts

- نظام التشحيم الانتهاء من مطحنة الأسمنت

- محطم عملية التوازن

- حجر محطم السعر بيرو

- ما هو حجم الجرانيت الألومينا

- استكشاف صغيرة الحجم كسارات الصخور القديمة

- مركز الرأسي مطحنة الأسطوانة الأسعار

- فواصل الذهب البرازيلي

- مشروع المواد المتعلقة بمعايير الأعمال الحجر المكسور

- الذهب كسر الجهاز

- خام الكروم في الصخور من الفلبين

- التحليل الميكانيكي كسارة الفك في مصنع الاسمنت

- جهاز مكافحة التلوث من كسارة الحجر

- مخطط تدفق تجهيز خام المنغنيز

- أفريقيا الكرة مطحنة الصانع

- بيع نواة النخيل شل محطم

- Open Cast Coal Mining Pdf

- Grinding Mill Scientific The Foos Mfg Co Spring Field Ohio

- Biaya Produksi Stone Crusher

- Off Grid Mines In South Africa

- Mine Drilling Rigs

- Ton Per Hour Rock Crushing

- Au Ag Epithermal

- Coal Dryer Crusher

- Gypsum Roller Crusher Indiaroller Mill For Gypsum

- Average Mining Compressor

- Stone Crushing Plant In Nigeriacrushing Plant

- Gold Mining Companies In Zimbabwe

- Images Of Marble Amp Amp Granite Wet Grinder Yb

- Sand Maker Made In Germany

- Fireclay Tile Crush Precio