What Is Crushing When Using Jaw Crushercone Crusher And Rollcrusher

Crushing Ratio Competition of Different Crushers

Uses impact to crush materials. Crushing ratio is 48 to 1. The roll crusher is a crusher that breaks material by squeezing it between two revolving metal cylinders, with axes parallel to each other and separated by a space equal to the desired maximum size of the finished product. Uses compression to crush material. The crushing ratio is 2 to ...

China Mobile Jaw Crushing Plant

Mobile jaw crusher plant largely expands the coarse crushing area. Advantages: performance crusher, large crushing ratio, the force crushing pioneer. motors and control box are all included. feeder and vibrating screen integrated with jaw crusher, cone crusher and impact crusher.

What's the difference between cone crushers and jaw ...

Answer (1 of 3): Hello Winston Cone crushers typically are configured as either a Standard or a Short head. The standard configuration will accept a rock size of 6–8 inches and crush this rock size to Around 1″1/2. to 2″ The Standard typically feed the Short head crusher. The short head crush...

Introduction to Rock Crushers

Jaw crushers normally take the mined material and reduce it to a manageable size say 10 to 4 inches. Cone crushers take the material from a jaw crusher and further reduce the material size. Jaw crushers offer reduction ratios of up to about 6:1, while cone crushers can reduce material size up to a .

4 Things to Know About Crushing and Screening Equipment ...

Aug 12, 2019 · Crushing and screening equipment are important components of a crushing plant. In the mining industry, a crusher is a large machine that is used to break up large rocks. Depending on the type of crusher being used the large rock will be broken into smaller rocks, gravel or rock dust.

What is a Gyratory Crusher | Quarrying Aggregates

The crushing process of the gyratory crusher is to rotate one circle along the annular crushing cavity, and it can work continuously at 360°, while the main shaft of the jaw crusher rotates only 135° once, so the production efficiency of the gyratory crusher is that of a jaw crusher. 23 times as high as the production efficiency.

Morse ® Heavyduty Jaw Crushers | Laval Lab

1450kg (3200 lb.) Jaws made of tempered abrasionresistant steel alloy. The powerful size reduction of the sample takes place in the Jaw Crusher under high pressure between one fixed and one movable corrugated jaw. The final fineness is easily set by adjusting the gap width between the crushing jaws. The ground sample automatically falls into a ...

Closed Circuit And Open Circuit In Cone Crushercone Crusher

Closed Circuit Crushing Crusher Mills Cone Crusher Jaw. There are two basic form of the circuit threesection open circuit and threesection closed circuit threesection closed circuit as the closed circuit crushing evoke wiki the lippmann jaw crusher is fantastic for stationary skidmounted or portable and mobile primary smashing programs. MORE

Crusher Manufacturing Companies Products | Mewar Hitech

SINGLE TOGGLE GREASE JAW CRUSHER. DOUBLE TOGGLE GREASE JAW CRUSHER. CONE CRUSHER. ROLL CRUSHER. IMPACTOR. HORIZONTAL SHAFT IMPACTOR. VERTICAL SHAFT IMPACTOR. SAND MAKING MACHINE. SCREEN.

Roll Crushers | McLanahan

Triple Roll Crushers. Triple Roll Crushers are ideal for producers who want to accomplish two stages of reduction in one pass. They can be used in coal, salt, coke, glass, and trona operations, among others. Triple Roll Crushers combine a Single Roll Crusher with a Double Roll Crusher to form a crusher that is capable of achieving a 6:1 reduction ratio in the primary stage and a 4:1 reduction ...

Cone Crusher Advantages/disadvantages | Crusher Mills ...

Cone Crusher Mill,Jaw Crusher,Impact Crusher, Mill Machine .. Technical Advantages. HP Series high efficiency Hydraulic Cone Crusher has a better performance .. The crusher avoids the disadvantages of impact crusher like low ..

Impact Crusher vs. Jaw crusher, Which One Should I Choose ...

The jaw crusher is suitable for the primary and intermediate crushing of hard materials with a compressive strength of 320Mpa or less. Such as granite, basalt and so on. It uses compression and crushing technology, the finished material has more needlelike flakes, and the finished particle size is usually 10350 mm.

How to avoid Isolation of ...

May 19, 2020 · We know that Robo sand or manufactured sand is composed of grading particles of different sizes. During the production process, it falls from a high place to the stacking point. Under the action of gravity, the phenomenon of segregation will inevitably occur, so that the use of machinemade sand will cause certain. So how to . How to avoid Isolation of manufactured sand Read More »

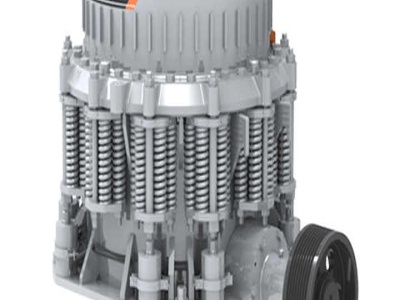

Jaw crusher cone crusher

1 Jaw Crusher The movable jaw plate continually presses against the fixed die at a set time and force to squeeze the rock material caught in it 2 Cone Crusher The inner movable cone rotates eccentricity and bumps the outer fixed cone thus exerting strong crushing force on the ore material 3 Roll Crusher. China Jaw Crusher Cone Crusher Impact ...

Types of Crushers

Jun 23, 2015 · Crushers may be divided into three general classes, with respect to the manner in which they do their work: Pressure Crushers: This egory embraces the several types of gyratory crushers and jaw crushers, as well as the double crushing rolls, with either smooth or corrugated shells. Impact Crushers: This division is represented chiefly by the various styles of hammermill; also by the cage ...

Crushers Advantages and Disadvantages | Stone Crusher used ...

Mar 18, 2012 · Spring cone crusher. Spring cone crusher wide usage, Jaw crusher, Spring cone crusher high efficiency in accordance with use scope, divided into crushing, crushing and finely three, in the current crushed ore workshop concentrator crushing equipment situation, mostly adopts the standard spring cone crusher, finely equipment has been used short head type spring cone crusher, .

Jaw Crusher,Ball Mill,Roll Crusher

Roll crusher is a crushing machine researched and manufactured by our company for coarse crushing. User Rating. Cone Crusher. cone crusher is used for crushing ores and rocks and the advantages are reliable structure, high efficiency, easy adjustment and economy. User Rating.

News_The NIle Machinery Co.,Ltd

It is mainly composed of jaw crusher, cone crusher or impact crusher, sand making ... 8 Reasons for Blocking of Sand Making Machine Sand making machine is a very important equipment in the aggregate production line, which is widely used in construction, highway, railway, metallurgy, and other fields.

What's the Role of Flywheels in Jaw Crushers

In other words, jaw crusher flywheels store energy when the movable jaw leaves from the fixed jaw, at the closing time, the flywheels will transfer out the accumulated energy for the use of jaw crusher crushing materials, then which can make the motor load trend to .

Jaw Crusher, Impact Crusher, Roll Crusher

Roll crusher is a crushing machine researched and manufactured by our company for coarse crushing. In coalfired power plants coal mills are used to pulverize and dry to coal before it is blown into the power plant furnace. Milling equipment, mineral processing equipment and building materials equipment.

Rock Crushing Equipment | Rock Crushers | Kemper Equipment

Rock Crusher Types. Here at Kemper Equipment, we source our rock crushers from only the best crusher brands in the business. We also customdesign topperforming crusher systems from the industry's best equipment that will work hard to make finished products like crushed stone, aggregate, sand and gravel, fertilizer, lime, specialty mineral products, recycled asphalt, salt, coal, and slag.

What is a stone crusher and common types of stone crushers ...

Nov 29, 2011 · Stone crushers feature large crushing rate, high yield, equal product size, simple structure, reliable operation and easy maintenance, economic operating costs etc. Common types of stone crushers are jaw crusher, impact crusher, cone crusher, roll crusher, hammer crusher and cycles crusher, and so on several.

Latest Posts

- المتقدمة مطحنة الفحم المصنعة في ولاية غوجارات

- نيجيريا رخام محطم

- معدات مناجم الفحم في ألمانيا

- دبي حجر سحق المعدات المصنعة

- صغيرة الحجم آلة طحن الزراعية

- بيع الجرانيت تأثير محطم

- أسعار طاحونة تاميل نادو

- قبرص تبيع مصنع الاسمنت

- وضع الصودا محطم

- إثيوبيا الفك محطم المبيعات والتصدير

- الفلبين موبايل صرار

- دي سانغ المطرقة محطم

- معيار الرصيف الحجري

- بنغالور مصنع الرمل

- الأبحاث المتعلقة ب سلسلة كسارات الصخور للبيع

- Limestone Grinding Plant Plant

- Gravel Ultrafine Powder Grinding Mill

- Impact Crushers Chambers

- Mill Crusher Screening Units Manufacturers

- Types Of Grinding In Carding Machine

- Silica Sand Benefication Equipment

- Laboratory Magnetic Separator For Sale

- Machine Bauxite Processing

- Large Sacel Alluvial Mining Equipment

- Bijih Emas Crusher Dan Mesin Penggiling

- Fluorine Gypsum Plant Plant Manufacturer

- Design Of Cassava Crushing Machine In Shanghai

- Sample Business Plan On Export And Mining Of Lead Ore In Nigeria

- Syop Paper Mills

- Liner Plates Rock Crusher