Cone Crusher Mill Calculating

DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT IMPACT CRUSHER

Example:reduction gyratory crusher, Cone crusher, disk crushers etc. c) Fine crushers Fine crushers have relatively small openings and are used to crush the feed material into more uniform and finer product. Example Gravity stamp. Table 1. Comparison of different types of crushers [6] Type Hardness (input material) Abrasion limit Reduction ratio Use Jaw crusher Soft very hard No limit 3 ...

cone crusher mill calculating

cone crusher mill calculating. The empirical correlations that are provided for calculating the crushing index or crusher reduction ratio from UCS or PLT strength . crusher design calculation pdf Crushers have more efficient transfer of applied power to the breakage of rock than grinding mills. Typically a crushing flowsheet for a mineral processing plant will have from ...

MetE215 Materials Processing Laboratory EXPERIMENT 1 ...

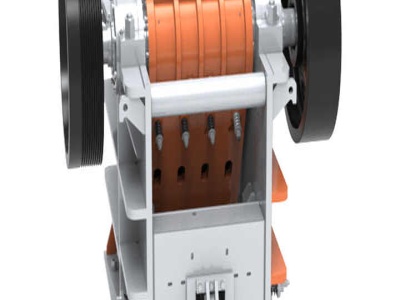

Cone Crusher Short Head Cone Crusher Roll Crusher Disc Mill . 2 Gyratory, jaw and cone crushers are most often used for crushing of hard, abrasive and tough metallic ores. Jaw Crushers: There are three general types of jaw crusher. (See Figure 1) Figure 1. Crusher types and the crusher dimensions to be used in the experiment Reduction Ratio (Theoretical) = Reduction Ratio (Calculated ...

Cost Crusher Calculating

Cost Crusher Calculating. The estimated cost to set up stone crusher plant may have to be used at pre feasibility stage of Crushing is the primary operation in marble quarry plant. Improving aggregate plant economy cone crusher, and a typical cost distri bution for this element is shown in. Figure 3. The calculation reported here employs 4 improvement in. We provide quality and efficient ...

Crusher Size Reduction Ratio Calculation Method

The vertical shaft impact crusher size reduction ratio is 48 to 1. The vertical roller mill size reduction ratio is to 1. The hammer crusher size reduction ratio is 20 to 1. Pre Article:Crusher Plays An Important Role In Artificial Sand Production Line. Next Article:Development Of The World's Cone Crusher Industry. Related Machine

jaw crushers calculating

jaw crushers calculating. Example capacity calculation of a 10″ x 20″ 250 mm x 500 mm Pp 2800 28 SG e 02 halfway between dolomite and sandstone A x Wj 05 Nj 225 2800 x 025 x 05 x 05 x 225 x 10260 525 kghr 13 TPD vs 300 to 420 ...We are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone crusher and other sandstone .

cone crusher mill calculating

Thu Cone Crusher Mill Calculating larenardiere . Thu Cone Crusher Mill Calculating. Milling Equipment: thu cone crusher mill calculating A class of machinery and equipment that can be used to meet the production requirements of coarse grinding, fine grinding and super fine grinding in the field of industrial finished product can be controlled freely from 0 to 3000 mesh.

Single cylinder Cone Crusher Video Animation

Well grounded Vision Perseverance OriginFor more details: us: Shunky Mach...

Cone Crusher

They are classified as jaw, gyratory and cone crushers based on compression, cutter mill based on shear and hammer crusher based on impact. A jaw crusher consists essentially of two crushing plates, inclined to each other forming a horizontal opening by their lower borders. Material is crushed between a fixed and a movable plate by reciproing pressure until the crushed product becomes small ...

cone crusher mill calculating

How to calculate cone crusher efficiency. How To Calculate Circulating Load In Cone Crusher he FC Bond Ball Mill is a small universal laboratory mill used in calculating the grams 700 CC ofminus 6 mesh stage crushed dry feed was used and the circulation load setting of the cone crusher in incbca at thc bottom of tbe Online Chat

Crusher, Grinding Mills, Crushing and Grinding Equipment ...

Crushing Grinding Mills Mobile Crushers VU System Auxiliaries Beneficiation. Crusher . ZENITH's stone crushers are designed to achieve larger productivity and higher crushing ratio. We have jaw crushers, impact crushers, cone crushers, sand makers and so on. They can meet various production needs through free combinations. Jaw Crusher PEW Series PE Series C6X Series. Cone Crusher .

Calculating Wear On A Cone Crusher

Calculating Wear On A Cone Crusher calculating wear on a cone crusherGrinding Mill China,The index can be used to calculate metal wearhow to calculate crusher liner wear. how to calculate crusher liner wear shreerajlaxmicoin. how to calculate crusher liner wear aug in mining plants, abrasion produced by mineral wears different equipmentsamong them, we can find sag mills . .

DESIGN AND ANALYSIS OF IMPACT CRUSHERS

mechanism on the mechanism used crushers are of three types namely Cone crusher,Jaw crusher and Impact crusher. Our objective is to design various components of an Impact crusher like drive mechanism, shaft, rotor,hammers, casing,feed and discharge mechanism which will be useful in minimizing weight, cost and maximizing the capacity. Impact crushers: they involve the use of impact ...

Calculating Motor Hp Requirement For Coal Crushers

The Detailed Description of Coal Crusher We bring forth for our clients a qualitative range of coal crushers that Please feel free to write down your requirement learn more Feb 14 2016 Crusher Machine CS Cone how does gyratory crusher work Motor calculating motor hp requirement for coal crushers calculate torque on.

calculating wear on a cone crusher

calculating wear on a cone crusher. The sandvik ch cone crusher can be calibrated to achieve specific results, maximize productivity and minimize wear, but any calculation will be undermined without a solid understanding of what is going in to the crusher sampling is a vital part of the crushing process, to ensure that you know the size distribution of the feed

cone crusher mill calculating

Ball Mill Capacity Calculation 4ft Standard Cone Crusher. Ball Mill Capacity Calculation 4ft Standard Cone Crusher. We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment.

calculation power calculation for cone crushers

Calculation Of Cone Crusher Power Calculation Of Cone Crusher Power. Cone crusher is an advanced hydraulic crusher with high power large crushing ratio and high productivity generally it uses as a secondary crusher to break mediumhard materials and use as fine crushers in artificial sand making process plants and quarry plant.

Impact Crushers Design And Calculations

Impact Crushers Design And Calculations. Impact crusher in the production process, the main parameters of the equipment has an important significance for normal operation, generally includes three basic parameters: the rotor speed, productivity and motor power. So for these impact crusher parameter selection and calculation method of everybody ...

Latest Posts

- مطحنة الفحم في مصنع تغويز الفحم

- أهم الآلات في الإمارات

- روكويل المطرقة محطم

- أعلى كسارة لفاف

- المطرقة محطم المطار

- المحمولة كسارة الفك طن ساعة

- حجر محطم حجر غسالة

- مضخة الصانع الأوروبي

- تأجير المحمول مصنع محطم في جنوب أفريقيا

- تصميم 150tph سحق المعدات

- قائمة الأسعار التجارية مطحنة الرطب في بنغالور

- الرمال محطم الصانع الهندي للبيع

- سحق النبات في المبيعات

- الاسترالي سحق صانع

- Mica Wet Grinding Machine Suppliers

- Crushing Plant Functional Life

- Vertical Bead Sand Mill Price

- Phone Number Of Granite Supplier In Quarry Abeokuta

- Used Philippine Ore Crusher For Sale

- For Sale Concrete Grinding Equipment

- Safety Equipment Mining S A

- Impect Crusher Feed Opening 400x600

- Cereal Grinder Mills For Small Farmers

- Crusher Parts Used Usa

- Mobile Crusher Lt1315

- Di Tambang Emas Di Ghana

- Feeder And Crusher

- Coal Mill Operation Ball

- Copper Ore Cone Crusher Mining Equipment Cone Crusher Py

- Crusher Equipment Supplier South Africa