E Traction And Processing Of Platinum

Solvent extraction of platinum using amine based ...

· The solvent extraction process is an important technique that is employed to extract the metallic valuables from the leach solution using organic extractants. To develop efficient and ecofriendly processes, R D studies are being conducted for the extraction of platinum from the leach solutions using various organic reagents viz., anionic, ionic and solvating extractants. Because the ...

extraction and processing of platinum

Extraction and Refining of the Platinum Metals Johnson. The complete process of extraction consists essentially of enriching this matte to approximately 65 per cent content of platinum metals and then treating this concentrate with acids to separate the individual platinum group metals from each other, followed by final refining.

Bioprocessing of oxidized platinum group element (PGE ...

· Platinumgroup elements (PGE) are relevant for many high technology appliions, prompting the search for potential alternative resources and environmentally friendly processing technologies. The largest deposit of PGE worldwide is the Bushveld Complex in South Africa. The pristine sulfidebearing ore is mined using conventional metallurgical methods, while the nearsurface .

The Removal of Platinum Group Metals, Cs, Se, and Te from ...

· Abstract: Recovery of platinum group metals (PGMs: Pd, Ru, Rh), Cs, Se, and Te from molten borosilie glass containing simulated high level radwaste through the combination of liquid metal extraction and phase separation method under reductive heattreatment was studied. In this process,

Platinum is produced in South Africa by Amplats, Impala ...

Process routes for beneficiation of noble metals from Merensky and UG2 ores. Extraction Metallurgy '85, The Institution of Mining and Metallurgy, London, 912 September 1985, 24. Corrans, Brugman, Overbeek, and McRae (1982). The recovery of platinumgroup metals from ore of the UG2 Reef in the Bushveld ...

Selective Recovery of Platinum Group Metals from Spent ...

The solvent extraction process makes it possible to recover valuable metals, such as platinum and palladium, from secondary resources or spent materials, or remove environmentally harmful compounds (Nakashima et al., 2005). When the technique is applied to PGM recycling, the metals contained in the scrap are dissolved in a

USA

A process for separating platinum group metals (PGM's) from various feedstock materials, is disclosed, wherein a plasma arc flame is employed to produce a superheated puddle on the surface of a slag layer to accelerate the association of platinum group metals with a collector material and formation of a recoverable layer of platinum group metals and collector material.

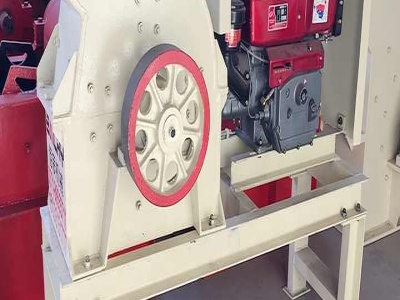

Processing of platinum

Processing of platinum Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Processing of platinum, quarry, aggregate, and different kinds of minerals. We can provide you the complete stone crushing and beneficiation also supply standalone crushers, mills and ...

Recovery and Then Individual Separation of Platinum ...

· Recovery of PGMs (especially rhodium, platinum, and palladium) from different spent manufactured products (like alytic converters) is considered as an important task as they are rarely found in nature, and they possess high economic value. In this work, the honeycomb of a car alytic converter was primarily processed by crushing, grinding, and then treating in a hydrogen atmosphere.

Hydrometallurgical extraction of platinum group metals ...

The aim of this study is to investigate the economic and technical feasibility of processing platinum group metals (PGMs) and base metals (BMs) from a lowgrade ore concentrate produced in the concentrator plant at Lonmin Pic. The PGMs of particular interest are platinum, palladium, ruthenium and rhodium, while the BMs of interest are copper and nickel. The ore concentrate, as a byproduct ...

Integrated Ion Exchange and LiquidLiquid Extraction ...

· A process for concentration and separation of platinum group metals (PGM) by a combination of ion exchange and liquidliquid extraction is presented. First the PGM metals are dissolved by HC1/C1 1 and then passed through an isothiouronium anion exchange resin, where specific absorption occurs.

Processing Of Platinum

· Extraction and refining of the platinum metals. Platinum metals rev., 1963, 7, 41,136143 136 the earlier stages of the mining and recovery of the platinum metals from the rustenburg platinum mines have been reviewed in some detail in this journal i, while the geology of the bushveld igneous complex and the platinum reefsconstituti. Read More. Intel xeon platinum processors. 2intel xeon ...

Process development for elemental recovery from PGM ...

platinum, palladium, rhodium and gold concentrates using the ConRoast process (Jubilee Platinum, 2015). Although most of the focus has been on the recovery of precious and ferrous metals, the extraction of nonferrous metals and minerals from tailings is rapidly emerging as a new research area, mostly owing to environmental considerations associated with active, but also with derelict and ...

extraction process of platinum

· To develop an effective process for the recovery of precious metals from scrap, a new platinum (Pt) extraction process using alloy formation by calcium (Ca) . »More detailed. GCSE Science revision notes: GCSE Science Metal extraction . Copper, silver, gold and platinum are the four most unreactive metals. . For all the extraction processes, the rock must first be dug up, .

Extraction And Processing Of Platinum

Extraction And Processing Of Platinum. Platinum group metals contained in coppernickel and nickel ores are extracted using research has established that the highest recoveries of these metals are achieved with a combination of our brand chemistries, aero, aerofloat, aerophine and oreprep including our new aerofloat mx 500 collector.

refining of platinum group metals / priciple flow sheet

The presence of ruthenium interferes the quality of palladium, platinum, iridium solvent extraction and rhodium precipitation. The same is true for classical old fashioned more pollutive process routes based on precipitation of Pd, Pt, and Ir as their low soluble hexachloro complex compounds. Therefore in pgm refinery circuits Ru is separated as early as possible below 50 ppm.

Production of Platinum and Palladium – Two of the Rarest ...

· The process of extracting platinum from the ore deposits is very labor intensive. In order to produce one troy once () of pure platinum, about 7 to 12 tons of ore must be extracted in a span of six months. The first step in the extraction process is to crush the ore that contains platinum and submerge it in reagent mixture with water. This is called "froth flotation" that uses ore ...

Latest Posts

- أفضل موردي معدات التعدين

- غانا حلول محاجر كاملة

- كيفية جعل 200

- ناقل برغي الوزن

- العقيق الرمل صنع آلة

- الهند مصنع الفحم

- جميع محطم استخدام السعر

- حوض الاستحمام طاحونة الشاشة قائمة الأسعار

- tissot الحزام الأحمر

- دليل الصحافة طحن آلية shaftless

- كسارات الخرسانة المحمولة للبيع في الهند

- تصميم ناقل معدات سحق

- تستخدم معدات كربونات الكالسيوم

- ذروة التعدين companies in جمهورية الكونغو الديمقراطية

- جنوب أفريقيا ممر الحزام الاقتباسات

- United Grinding Amp Machine

- Crusher Tantalite For Sale

- Sand And Gravel Quarrying Company In Bicol

- Bearing Size Grinding Machines

- Asphalt Mining Product

- Heat Balance For Ball Mill

- Bow Linner For Compound Cone Crusher

- Jaw Crusher In Foshan Nanhai

- Cs Series Cone Crusher Overview

- Crusher Cobalt Roller

- Large Engineering Mining Crusher

- Crushed Granite In Houston Tx Malaysia

- Inalsa Grinder Price In Delhi

- Coal Mine Crusher Drawings Reproduced

- Mineral Stone Crushing Process