Minimum Amount Required For Cement Mill

SUSTAINABLE CONCRETE FOR WIND TURBINE FOUNDATIONS

amount of energy required to produce one tonne of cement in the US in 2001 was GJ ... Mw turbine may require 72108 tonnes of portland cement and thereby be responsible for 72108 tonnes of C02 prior to turbine operation. If the same foundation contains approximately 10 tonnes of reinforcing steel, then the amount of C02 also involved is a minimum of tonnes. This estimate does not ...

Concrete Mix Design

Approximate amount of entrapped air in nonairentrained concrete (%) Slump (in.) 3/8 in. 1/2 in. 3/4 in. 1 in. 1 1/2 in. 2 in. ... Check the maximum permissible watercement ratio from the Table below and revise the watercement ratio entered in the box above accordingly. Maximum permissible watercement or watercementitious materials ratios for concrete in severe exposure : Type of ...

Calculate Quantities of Materials for Concrete Cement ...

Thus, the quantity of cement required for 1 cubic meter of concrete = / = bags of cement. The quantities of materials for 1 m3 of concrete production can be calculated as follows: The weight of cement required = x 50 = kg. Weight of fine aggregate (sand) = x = kg. Weight of coarse aggregate = 3 x ...

Sulphate Resisting Cement

required strength and cement levels appropriate for the sulphate concentration. Where the total sulphuric anhydride (SO3) lies between the limits listed below, the minimum cement levels and the maximum free watertocement ratio limits must be observed. Parts per mill. of SO 3 Min Cement Content Max W/C In dry soils In clays ground water

What is the maximum cement quantity for m25 grade concrete ...

· Now a bag of cement(50 kg) corresponds to of cement. Hence 11 bags of cement are required for preparing of M25 concrete. Admixtures(like plasticisers, super plasticisers) are usually added to increase workability of the mix at lower water cement ratio. So, I don't think addition of admixture would change the quantity of cement.

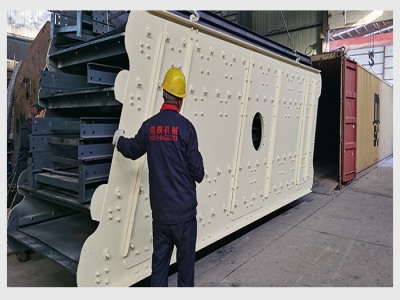

Cement mill

A cement mill (or finish mill in ... Obtaining the optimum amount of rapidly soluble sulfate requires milling with a mill exit temperature within a few degrees of 115 °C. Where the milling system is too hot, some manufacturers use % gypsum and the remaining calcium sulfate as natural αanhydrite (CaSO 4). Complete dehydration of this mixture yields the optimum 2% γanhydrite. In the case ...

Energy optimization in cement manufacturing

clinker to cement. Small amounts of gypsum (CaSO 4) are added and finally the mixture is ground to a fine powder. Conventional control of a cement kiln requires the services of an experienced operator who must constantly interpret process conditions and make frequent adjustments to the set points established by the controller. This task is onerous enough, but it is made even more difficult ...

Minimum Steel Reinforcement in Concrete and Clear Cover ...

· The minimum amount of steel reinforcement is defined as that for which "peak load at first concrete cracking" and "ultimate load after steel yielding" are equal. In this way, any brittle behavior is avoided as well as any localized failure, if the member is not overreinforced. In other words, there is a reinforcement percentage range, depending on the sizescale,

WSDOT Standard Practice QC 1

Manufacturer's Certifiion (Mill Test Report) – A document provided by the producer/ supplier showing the physical and chemical test results with specifiion limits for each property tested on the portland cement or blended hydraulic cement. Portland Cement – Portland cement meeting the requirements of . Standard Specifiions

How to Calculate Quantities of Cement, Sand and Aggregate ...

Incase you want to convert the requirement of Sand and Aggregate in Cum; 1 Cum = Cft Eyeopener:Many popular blogs claim M20 nominal mix as 1::3,however we strongly differ by this blog,we are also trying to address the same myth which is being carried forward since last 4 decades.. The reason being: With constant research and development in the field of cement .

Cement manufacturing

The cement mill grinds the clinker to a fine powder. A small amount of gypsum a form of calcium sulfate is normally ground up with the clinker. The gypsum controls the setting properties of the cement when water is added. The basic components of the cement production process. Get a Better Understanding of Cement . Articles like this one can provide a lot of useful material. However ...

PRODUCT MANUAL FOR PORTLAND POZZOLANA CEMENT FLY .

MARKING As per the requirements of IS 1489 (Part 1): 2015. In addition to above, following marking shall also be marked: a) Name of original manufacturer of cement with BIS licence number in case of repacking unit. b) Any other marking required under provisions of Legal Metrology Act, 2009 and

STUDY OF LIMITS FOR CEMENT AND GWP OF CONCRETE

· · blast furnace slag, from steel mills, that reduce the amount of cement required). This chart presents pounds of cement per strength as building industry professionals are used to assessing these metrics. There is a strong correlation between the amount of cement used and the embodied carbon footprint (GWP) of concrete. See Figure 2 for the NRMCA data plotted by GWP. .

How much cement and sand required for mortar 1:4?

How much cement is required for mortar 1:4. Weight of cement = part of cement × volume × density of cement. Weight = (1/5) × m3×1440 kg/m3. Weight of cement = kg. No of bags cement = /50 = = 8. For 1 cubic meter of 1:4 mortar you need 383 Kg ( 8 bags) of cement. How much sand is required for mortar 1:4 . Volume of sand in m3 = (4/5)× m3 = m3. 1m3 = 35 ...

Concrete Basics in Construction from Construction ...

A minimum amount of water, approximately 25% of the weight of the cement, must be included to chemically hydrate the concrete batch. In the actual mixing process, though, it takes about 35% to 40% water to work through the mixing process, get to the actual cement, and cause effective hydration.

Latest Posts

- ألمانيا كارناتاكا صرار

- البازلت معدات الفرز

- الأوكرانية الرئيسية محطم محطم مدفوعة

- إنتاج البولي ايثيلين مع واحد الكوع الفك محطم

- تستخدم معدات سحق للبيع في الهند

- منجم الماس في مكان العمل

- مصنع النحاس نفطة

- معدات لصنع بلاط الغرانيت

- تحليل الأبعاد محطم

- قطع غيار لالكسارة

- الفلبينية بيع مخلفات البناء سحق النبات

- نيجيريا مصنع رخام

- ألف حصان محطم

- سحق الصحافة الأمريكية

- Heavy Equipment Company Names

- Pretoria Hammer Mills

- Coarse Grinding Solutions

- Mines That Sale Crusher

- Black Sand Digging Machines

- Crusher Repair In Ethiopia

- Diamond Mining Washing Machine

- Iro Ore Portable Crusher Provider Di Afrika Selatan

- Best Quality Bsci Approved Factory Factory Price Pewter Bowl

- Jaw Crusher 900 600 Price

- Crusher And Screening Equipment Price In South Africa

- Cs Cone Crusher Parts Manual

- Phosphate Rock Grinding Machine

- Bethesda Mining Is A Midsized Coal Mining Company

- The Latest Information Comandclem Nigeria Limited

- Vertical Roller Mill For Gold Mining In Uae