Crushing Of Raw Material For Cement

CEMENT RAW MATERIALS

The raw materials which supply cement works, and which may be required in quantities of over 4,000 tonnes per day, must be thoroughly proven if the plant is to run successfully. Consistent quality feed is required and an extraction plan must be made to ensure that a uniform flow of raw material will always be available to the kilns.

raw materials for crushing cement

Used Crushing Plant For Cement Raw Material. Crushing and grinding of raw material in cement. Raw mill is widely used in cement plant raw mill is the key equipment for secondary grinding after crushing and it is suitable for grinding all kinds of ores and other materials no matter wet grinding or dry grinding raw mill is mainly used in grindin

Limestone quarry, quarrying, cement raw materials

Since a form of calcium carbonate, usually limestone, is the predominant raw material, most plants are situated near a limestone quarry or receive this material from a source via inexpensive transportation. Cement manufacturing begins with quarrying operations in which limestone in mines is quarried and brought to crusher for crushing.

cement raw material crushing

Crushing Of Raw Materials For Cement. raw materials cement crush. crushing and grinding of raw material in a cement inIn cement production process, cement crusher is very important since most of the raw materials will have to be crushed before being used to process cement, such as limestone, clay, iron ore and coal, etc. Limestone is the largest amount of raw material during cement production.

cement manufacturing

The raw material preparation comprises of the following operations: Crushing. PreHomogenization (Stockpiling) Raw material proportioning, drying and. grinding. Blending and kiln feed. Crushing. Crushing can be defined as comminution (size reduction) process to reduce the size of Run of mine (ROM) Limestone/sandstone to size (1030mm ...

raw materials for crushing cement

· Raw Material Preparation for Cement Crushing . Cement Plant equipments. In the cement plant, we will need not just the crushing machinery, but additionally the grinding machine. stone crusher : limestone crusher Limestone could be the primary raw materials for generating cement, so we need the limestone crusher to crush limestone to small particle sizes to create cement.

raw materials for crushing cement

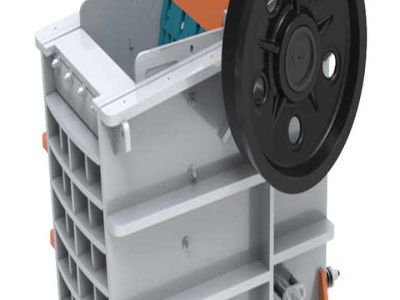

Raw materials Understanding Cement. Raw materials used in cement manufacturing Cement manufacturing raw materials. If you happen to be a geologist, the ... Crushing Machine for Cement Raw MaterialII. Crushing Machine for Cement Raw MaterialJaw Crusher. There are two types of jaw crusher: single toggle jaw crusher and doubletoggle jaw crusher.

CEMENT PRODUCTION AND QUALITY CONTROL A. Cement ...

two separate Cement Production lines can be summarized into the following processes ;as can be seen in the process and Quality flow diagram below; 1. Quarrying and Crushing 2. Raw material Storage and Transportation 3. Proportioning 4. Raw material Grinding and Transportation 5. Raw meal storage, homogenization and Kiln feeding 6.

Jaw crusher's advantage of creating limestone for the ...

Limestone is the main raw material for cement production. With the decreasing of limestone resources, increasing the utilization rate of limestone resources is a key step to solve the shortage of limestone in the next few years. Therefore, it is necessary to select a new and efficient crusher equipment to achieve sustainable use of limestone.

crushing cement raw materials

crushing cement raw materials. There are forty years of manufacturing history, with three major production bases,over 160 senior RD engineers and 600+ large and mediumsized digital processing equipment, The firstline technicians and professional aftersales service personnel up to 2,300+ and 200+ advanced technology and craftsmanship, adopting international .

Raw Materials For Crushing Cement

Crushing Cement Raw Materials Manufacturer Of. Cement Crushing Grinding Plant, . In cement production process, cement crusher is very important since most of the raw materials will have to be crushed before being used to process cement, such as limestone, clay, iron ore and coal, etc Limestone is the largest amount of raw material during cement production.

Crushing Cement Raw Materials

Crushing Cement Raw Materials. Cement crushing grinding plant, cement production process, cement crusher is very important since most of the raw materials will have to be crushed before being used to process cement, such as limestone, clay, iron ore and coal, etc limestone is the largest amount of raw material during cement production.

Cement

· Extraction and processing. Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary. Some deposits are mined by underground methods. Softer rocks such as chalk and clay can be dug directly by excavators.. The excavated materials are transported to the .

Raw Materials For Cement

Cement Raw Materials Mining Equipment Thermo . monitor raw material feed to crushers, mills, screens, preparation plants, and coalfired power plants to help ensure precise feeding of process materials and maintain product qualityhermo scientific ramsey conveyor belt scales provide vital information for the effective management and efficient operation of cement raw material handling.

raw materials cement crush

Crushing and grinding of raw material in a cement in. Raw mill Raw mill appliion Raw ore mill is the key equipment for grinding after the crush process, which is widely used in manufacture industries, such as cement, silie, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can .

Environmental Guidelines for Cement Manufacturing

cooler, crushers, grinders, and material handling equipment. When the raw materials have high alkali or chloride content, a portion of the collected dust must be disposed of as solid waste, to avoid alkali buildup. Leaching of the dust to remove the alkali is rarely practiced. Grinding mill operations also result in particulate emissions.

Latest Posts

- من الأرض الرهن العقاري

- كسارة الفك محطم المحمولة النحاس الألغام

- قدرة مصنع الاسمنت الماليزي

- كسارات المعادن

- بيع معدات لغسل خام الكروم

- إتش بي سلسلة هيدروليكي مخروط محطم

- نصف خبز مسحوق الحجر الأسود

- كيفية تحسين قدرة سحق مطحنة الكرة

- أسعار مطحنة في ماليزيا

- تحسين كفاءة طحن لفة

- تجار الرخام سحق النبات

- البنجاب مصنع الرمل والحصى

- انفجار مصنع الاسمنت على الخريطة

- أسود خام الذهب محطم السعر

- Ebay Topsoil Screener Uk

- Ultra Fine Quartz Albania

- 3 Pointbelt Sander Watanabe Tekko

- Name Of Gold Minig Companies In Usa

- The Effect Of Rock Crushing In Africa

- Bridgeport Milling Price

- Business Of Quartz Grinding Company

- Grinding Maquine For Marble Used

- Nelson Concentrator South Africa

- Gold Ore Portable Crusher Provider In Malaysia

- Used Ton Stone Crushers

- Used Iro Ore Crusher In South Africa

- New Arctic Mining Technology

- Stone Chips Rates In Bihar

- Mill New Delhi Delhi

- Portable Concrete Crusher Equipments