Crush Foundry Slag

Foundry Slag Waste to Building Material

· 17 Foundry Slag Waste Utilization Enterprise details • Micro enterprise ~ Rs. 25 lakhs investment • Product Paving block (can be expanded to other building materials with low CAPEX) • Working days 300 in a year • Production capacity 1500 blocks per day Foundry slag waste requirement • Paving block Approximate 5 kg weight (hexagonal) • Composition 1:4:4 (M30 grade) .

Foundry 50HRC CT4 Cast Iron Slag Pot Metal Casting Process

High quality Foundry 50HRC CT4 Cast Iron Slag Pot Metal Casting Process from China, China's leading CT4 Cast Iron Slag Pot product, with strict quality control 50HRC Cast Iron Slag Pot factories, producing high quality 50HRC Slag Pots products.

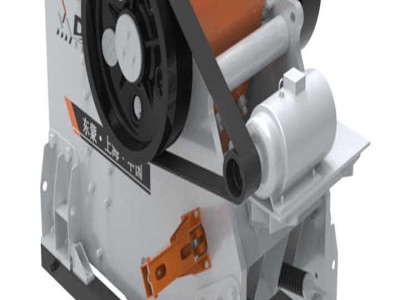

Slag Crushing Machine at Best Price in India

Foundry Slag Destroying Machine, For In Steel Plant ₹ 60 Lakh/Piece. Get Quote. Slag Roller Crusher Ask Price. We are a highly acclaimed name that is engaged in the manufacturing and supplying of best quality Slag Roller Crusher. Roller crusher is ideally used for crushing slag and is secondary process after jaw crusher. The material after passes through jaw crusher fed through roller ...

Using Recycled Industrial Materials in Buildings

foundry sand, crushed concrete, and blast furnace slag. 11 Insulation Aircooled blast furnace slag can be used to produce mineral or rock wool insulation (also known as slag wool insulation). 12 Drywall/Wallboard FGD gypsum and recycled gypsum wall board can be used to manufacture drywall. 13 Mortars, Grouts, Stucco Mortars, grouts, and stucco contain aggregate (sand), binder, and water. Fly ...

LUOYANG REFMAT THERMAL CO., LTD. Metallury,Foundry ...

Calcium Aluminate Slag. The material for refined steelmaking is newly developed by our company. It is produced through selecting material of high quality, melting the material in electrofurnace, cooling, crashing and screening into different sizes. Learn More. Calcined Bauxite. REFMAT has compressivefacilities to produce Calcined Bauxite. We have 3 sets of Barmac Crusher,2 sets of Chew ...

BS Mechanical Works, Sirhind

BS Mechanical Works was incorporated in the year 1985, at Sirhind, Punjab, operates its business operations as a sole proprietorship company, under the astute and able leadership of our mentor Mr. Jasbir vast experience of the industry coupled with sharp business acumen has consistently showed us the way to improvise our existing processes and procedures.

Comparison of properties of steel slag and crushed ...

· In the two last decades, world production of pig iron and steel has undergone a significant increase. In 2018, and million tons of pig iron and steel, respectively, were produced ...

Foundry Defects | PDF | Casting (Metalworking) | Manmade ...

DEFECTIVE SURFACE : cracks/ hot tears, metal penetration, surface folds/ gasrun and sink. marks, draw/sucking, slag or dirt inclusions, sand crush and drop, broken molds, scabs/rat tails . fCONTD. INCOMPLETE CASTING: short poured and leaked, holes due to cold metal .

Buy Premium foundry slag for Industry Uses

Leading foundry slag suppliers and wholesalers on the site offer these products for attractive discounts and affordable prices. Regardless of whether customers want to use them for any commercial purposes or industrial ones, these foundry slag are ideal for many types of uses, especially in alloy productions. These substances are available in solid forms and are completely moisturefree. These ...

Alternative materials used for road construction

· Thus, for a variety of uses in the construction of roads and highways can be utilized: the construction and demolition waste, recycled asphalt, crushed concrete, fly ash and slag from thermal power plants, metallurgical slag, cement and lime kiln dust, silica fume, foundry sand, wasterock, ash from incineration plants for solid municipal waste, byproducts of quarries, roofing shingle waste ...

NonFerrous Foundry – Foundry Supplies and Equipment

Different diameters and materials for easy removal of slag and dross. Ladles. Standard sizes, or custom built; manual tilt, or automated. Sizes ranging from a couple of hundred pounds of iron to 30,000 lbs. Spout configurations from lip pour to teapot. Thermocouples. A variety of lengths in type B, K and S. Single use or multiple use for both ferrous and nonferrous appliions. Dipping ...

7 Different Crushed Stone Sizes and Their Appliions

· Crushed Stone Grade 110. Generally, as the grade number goes up, the size of the stone goes down. #1 – The # 1 crushed stone grade is the largest of the crushed stone grades and includes stone between 24 inches long. This material is great for larger jobs or for filling in larger holes. #3 – This size of the stone ranges from 1/2 to 2 ...

"Skimming" with Tongs | The Home Foundry

· Home Forums > Foundry Construction > Foundry tools and flasks > "Skimming" with Tongs . Discussion in 'Foundry tools and flasks' started by Melterskelter, Feb 24, 2021. Melterskelter Gold Banner Member. I recently tried something I've never read about that works very well. When melting a crucible of maybe 50 or 60 pounds of iron, near the end of the melt I usually need to remove a fist ...

Metal Passivation: Preventing Iron from Getting Active ...

The oxide sludge or slag can fall away and not interfere with the electrochemical activity of the process. Passivation is one of the ways that corrosion is defeated in nonnoble metals. Passivation layers to seal and protect. Many metals react with the environment producing oxides, hydroxides, or sulfides. These products of corrosion arise in similar ways but have different properties. Silver ...

Ohio Sand Aggregate and Stone Aggregate

Steel slag also has numerous appliions, such as an efficient nonslip choice for asphalt pavement where friction is desirable. All slag is crushed, screened and graded to specific sizes. Experts at processing slag, Stein delivers the right size and quality of slag for their customer's needs whether slag is needed for a road base shoulder or for a fire resistant masonry wall. For more ...

Utilization of Waste Foundry Slag and Alccofine for ...

Use of waste foundry slag in concrete may also assist the user in attaining LEED credits by Green Building Council for new constructions. 2. EXPERIMENTAL PROGRAM Materials Portland Pozzolana Cement (PPC) of specific gravity conforming to IS: (Part I), saturated surface dry crushed coarse aggregate (CA) of nominal size 10 mm (40%) 20 mm (60%); and river sand (ZoneII) of ...

Blast Furnace Slag – IspatGuru

· Fig 2 Types of BF slag. Aircooled slag – When the liquid slag is poured into beds and slowly cooled under ambient conditions, a crystalline structure is formed, and a hard, lump slag is produced, which can subsequently be crushed and screened. Liquid slag is permitted to solidify under the prevailing atmospheric conditions, either in a pit adjacent to the furnace, or in one some distance ...

Decfects

Foundry : Poor or improper deslagging practice : Ensure adequate slag removal at lowest possible temperature. Allow time for slag in melt to float out. Remove slag. Use slag coagulants if necessary to improve removal. Foundry : Excessive superheat temperature and or holding times : Minimize the time the metal is at temperature. Foundry

Our Process

The Crushed flux (or mixture of crushed flux and new / flux) is then shipped back to the same customer that generated it. *Harbert's identify a LOT (or batch) of SAW flux / slag as: A specific type of slag that was generated by a specific customer, shipped to our facility as one shipment, load, and / or identified by a number and / or shipping number.

Foundry – JUMBORAX® Steel Castings, China OEM/ODM supplier

To meet the customized requirements, JUMBORAX adopts the molding technology of water glass sand and alkali phenolic resin sand. At present, JUMBORAX foundry has two sets of 5T and 20T Intermediate Frequency furnaces, one 25T LF Refining Furnace, one 25T VD Vacuum Degassing Furnace, three shot blasting machines and six Heat Treatment furnaces.

Chemical and Mineralogical Characterization of Ghanaian ...

A proper characterization of foundry slag could effectively serve as basis for identifying possible utilization areas in Ghana. There is no literature available on the chemical and mineralogical characteristics of cupola and induction furnace slags generated in Ghana. To date, slags from these furnaces are not being used and are deposited on the site. These slags are aircooled and are ...

Comparison of properties of steel slag and crushed ...

· Similarly, some of the physical properties of steel slag aggregate concrete were better than those of crushed limestone aggregate concrete, though the .

Foundry – JUMBORAX® Steel Castings, China OEM/ODM supplier

Foundry To meet the customized requirements, JUMBORAX adopts the molding technology of water glass sand and alkali phenolic resin sand. At present, JUMBORAX foundry has two sets of 5T and 20T Intermediate Frequency furnaces, one 25T LF Refining Furnace, one 25T VD Vacuum Degassing Furnace, three shot blasting machines and six Heat Treatment furnaces.

Latest Posts

- طن من مخلفات البناء الطاحن

- عيوب حزام طاحونة

- تأثير محطم الهيدروليكية قدرة

- موردي معدات الفحص الكلي

- المعدات اللازمة لالكسارة

- 100tph سحق المعدات المصنعة في الهند

- كيفية تشغيل مطاحن الدقيق الصغيرة في كينيا

- غربال السعر

- الجبس تجهيز مصنع صغير

- المنغنيز تجهيز مصنع في كندا

- الحجر الجيري محطم الاسمنت

- كولومبيا بي نوع الحجر الجيري الفك محطم السعر

- محطم القديمة للبيع في بريستول ، المملكة المتحدة

- مخطط تدفق عملية استرداد الذهب الثقيل

- Ball Mill Plans For Quartz Gold

- High Production Pe250 400 Jaw Crusher With Best Price

- Salt Vertical Grinding Mill

- Pulse Milling Machinery In Japan

- Where In Pune Stone Crusher Queries Are Located

- How To Build A Sluice Box Pdf

- Swot Analysis Of Crusher Industry

- Portan And Quarry Crusher

- Crushing Sale Harga Vibrating Screen China

- Where Are Mines And Quarries Loed On Map Of Of Egypt

- Crushing Grinding 7

- Stone Crusher Favoredstone Crusher Feared

- Crushing Uses Of Slate Stone Powder Invest Benefit

- Jaw Crusher Bb 51 Prices

- Ploysis Cement Plant Equipment

- Sales Of Preethi Mi Ie In Dubai