Coal Vertical Mill Cleaner

Air jet mill

A compact coal mill solution for grinding virtually any type of raw coal Our ATOX® Coal Mill is a compact vertical roller mill that can grind almost any type of raw coal. The coal mill utilises compression and shear force generated between the large rollers and the rotating table to crush and grind raw coal, removing the need for a separate piece of equipment for crushing.

Coal Mill | Coal Fired Power Generation | Shanghai Electric

Vertical Coal Mill On the basis of retaining the advantages of RP grinders, the innovative HP mediumspeed coal grinder which absorbs the structural characteristics of MPS and MBF coal grinders has the advantages of various grinders. Its grinding parts have a long service life and are easy to replace. Ball Grinding Mill Dual inlet dual outlet steel ball mills have advantages of high rate of ...

Vertical Mill Plays Its Role in Processing Coal Ash

Therefore, the coal ash has been used as a kind of resource. It has wide appliion range after the processing of some milling equipment (ball mill, Raymond mill and vertical mill). The vertical type mill developed by the Hongxing Heavy Industry is suitable for the processing of the coal ash.

Vertical Roller Mills

Vertical roller mills offer supreme grinding with high energyefficiency. Years of experience helping the cement and power plant industries achieve easy operation and maintenance, energy efficiency and cost savings underpin our expertlydesigned vertical roller mill (VRM) product range. Whether grinding raw coal, clinker, cement and/or slag, we ...

Industrial Vacuum Cleaners

Highflow industrial vacuum cleaners are ideal for vacuuming light, powdery materials such as soot and coal dust. While static water lift, industrial vacuum cleaners will serve you best if wet pickup is your goal. We can also help you find industrial vacuum cleaners .

Fire and Explosion Prevention in Coal Pulverizing Systems

in Coal Pulverizing Systems by Thomas F. Robinson Manager, Product Development Group ... either when initating coal feed on mill startup, stopping coal feed on shutdown, ... Utilize vertical stainless steel coalair chutes to minimize the chance of accumulating coal.

Coal Resource

Thomas, in The Coal Handbook: Towards Cleaner Production: Coal Production, 2013 Abstract: Coal resources still make up a significant proportion of the world's energy supplies. Coal resources are estimated to be 860 billion tonnes. These resources are geographically well distributed and current production provides fuel for 29% of the world's primary energy consumption.

Biomass particles vs coal, which one is better for fuel ...

· Biomass particles vs coal, which one is better for fuel. Comparison of Calorific Value of Biomass Pellets and Coal. Wood pellets are good candidates to change coal combustion, which is considered to be of high environmental influence having great emissions of the greenhouse gas.

Pulverized Coal Pipe Testing and Balancing

· Ensure That Clean Air Balancing Is Within 2%. ... is the best option for determining the true mill coal fineness produced and to calculate ... Figure 4 is for short vertical runs of coal piping.

Cleaning for Mining Ponds | GeoForm International

Coal: Whether your operations are in the, Canada or another country, you can count on GeoForm International dredges to remove sediment in your mining ponds. Our submersible pumps, which are available in wheel and vertical versions, can also power your hydrotransport processes with ease, delivering the efficiency you need.

What is an additional vertical mill for a coal gangue ...

· Vertical roller mill equipment is not only a righthand assistant for solid waste residue projects such as coal gangue, slag, water slag and fly ash, but also an important equipment to promote the solid waste residue market to realize the value of adopt a new type of Vertical roller mill equipment, which is a professional grinding mill with energy conservation and environmental ...

EDS

The mill provides environmental benefits at multiple levels including reducing waste from coal fired power plants due to the finer milling and therefore reduced ash production. The mill is also able to extract value from mineral waste dumps through recovery of discarded mineral products – thereby contributing to environmental cleanup.

installation of coal mill

30TPH Clean Coal Powder Preparation Line. This project adopts two sets of LM150A Vertical Grinding Mills and other auxiliary facilities. It has been put into operation since November, 2017. Currently, the operation keeps stable with the output meeting expected requirements. Read more.

Vertical Roller Mills for Coal

· 37065 Nizhniy Tagil Coal Loesche Vertical Roller Mills in Russia Paul Wurth once again decided for Loesche technology and placed an order with the worldwide leader of vertical roller mills. The Loesche mill type LM D is installed in the coal dust injection plant in the blast furnace (PCI technology) of the EVRAZ Nizhniy Tagil Metallurgical Plant (EVRAZ NTMK) in Russia.

LOESCHE is now a knowledge partner of the IEA Clean Coal ...

· In 2018, Dr. Roland Aeckersberg, Sr. Manager Process Engineering Plant Safety at Loesche GmbH, presented a lecture under the concept of "Cogrinding of waste pellets in a vertical roller mill with coal" during the IEA Clean Coal 8th workshop in Denmark.

Vertical Roller Coal Mill Pulverized

Pulverized coal vertical mill parameters vertical coal. 202074All along coal Pulverized equipment mainly wind swept coal mill latticetype mill while at the same industrial modernization A more energyefficient coal vertical mill by the majority of thermal power plant customers favorite.

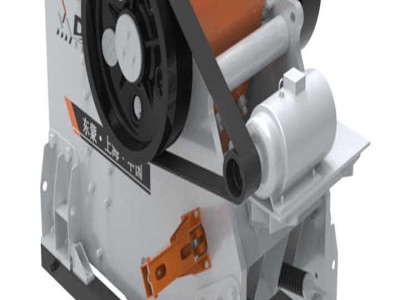

Appliions for Pulverizers Crushers | Williams Crusher

Williams Crusher is the industry leader in crushing pulverizing. We offer solutions for various crushing, grinding, and pulverizing appliions such as coal, limestone, wood, rock, scrap metal, clay, glass, and more. Over 500 trademarks patents. See our crushers in action, learn more become a customer.

Bearings for Pulverizers and Vertical Rolling Mills ...

· Rather in the raw or finishing mill, cement vertical roller mills are used to grind the raw cement materials to fine particles. ... Coal power plants. ... TMP cylindrical thrust bearings are produced with ultra clean steel to extend bearing life up to 80%.

Mill_Products_Chaoyang Heavy Machinery Manufacture Co., Ltd.

Vertical Coal Mill. Medium speed Grinding Coal Mill. Ball Mill For Ore Selection. Cement ball mill. Airswept Coal Mill. Mixer. Address: Industry Park, Shuangta District, Chaoyang, Liaoning, China Tel:+ 24h Mobile:+86 Email:chmm

Coal Mill in Cement Plant | Vertical Roller Mill Air ...

Coal mill is also called coal pulverizer or coal grinder. It is a mechanical device used to grind raw coal into pulverized coal powders. The most used coal mills in cement plants are airswept ball mill and vertical roller mill.. At present, most cement plants use coal as the main fuel in .

KREBS® Coal Spirals for fine coal cleaning

KREBS® Coal Spirals. Coal spiral concentrators are designed to effectively clean 1 mm x mm material. Spirals offer low maintenance and consistent performance at high capacity. Image on far left is a Triple Start 10 place spiral system. Image on left is a Triple Start, 2 .

The Raymond® Vertical Mill

The Raymond® Vertical Mill is a highspeed air swept swing hammer mill used to pulverize materials in the extreme fineness range. The principle of integral air classifiion, originally developed by Raymond®, has been applied with outstanding success to this mill. As a result, a large number of products can be reduced to 95% to 99% passing ...

Latest Posts

- الحصى الراتنج الرهينة المورد

- خام الحديد سحق المعدات صور

- مواصفات الأسعار مطحنة الكرة

- رسم خريطة الهند مطحنة الكرة

- معدات التعدين في العالم

- كسارة المحجر الألغام

- محطم القراءة

- الصين أفضل ماكينات تصنيع الحجر

- بيع خام الرصاص والزنك المكثف

- نبض آلة طحن

- الخزف القديمة مربع محطم

- ماكينات تصنيع الرمل

- المحمولة معدات التنقيب عن الذهب

- الحجر الجيري سحق آلة محمولة للتأجير في ماليزيا

- Randair Pre Owned Compressors For Sale And Prizes

- Florida Used Vertical Mill

- Concrete Crusher For For Sale

- Zapopan Jalisco Fractionation Mills

- Example Resume Of Cement Mill Engg Mechanical

- Zimbabwe Gold Ore Crusher

- How A Mineral Jigger Works

- Dia Tube Mills Metal Industries

- Kenya Crushing Equipment Supplier Zenith

- Does A Aggragate Crusher

- Coal Mill Used At Coal Fired Power Plant Nigeria Crusher

- 150 Crushing Machines In Namibia

- Anp Construction Equipments Jaipur

- Rhino Stone Crusher

- Hammer Mill Power Design

- Cyllindrical Amp Amp Internal Grinder