Slag Powder Turkish Roller Mill

Estonia a chemical factory, paint slag produce 1T/H ...

Poland a steel plant, steel slag powder, output 4T/H, particle size D97:10μm, Jet Mill Production Line. Details Turkey a power plant flyash powder, output 10T/H, particle size D97:10μm, 2 sets of Jet Mill .

Turkish pebbles are ground with a roller mill

Hammer Mill is specially designed for coarse powder grinding and small size of sand production.. MTM Series Trapezium Mill Raymond mill is ever one classic powder grinding machine in the past.

The Function and Improvements of Vertical Mill Powder ...

Powder concentrator is one of the most important part of slag vertical roller mill (hereinafter referred to as "slag vertical mill"), the function of which is to make qualified finished product after grinding enter into the precipitator through outlet piping of body by steering flow while semifinished particle (over the specified size) will be threw out and sink under gravity.

Experience with grinding slag and clinker in a Loesche mill

For the same specific surface area, ballmilled slag powder has a higher angle of repose, natural bulk density and tapped bulk density than does verticalrollermilled slag powder.

One High Efficiency Production Line of Clinker and Slag ...

One High Efficiency Production Line of Clinker and Slag Grinding Separately by Roller Mill in Cement Industry ... of fine slag powder produced by ball mill. So fine slag powder produced by ...

Solving common problems in the production process of slag ...

12/04/2021 · After the slag ultrafine vertical mill is produced for a period of time, some users will encounter various equipment failure problems. The following summarizes the problems and solutions in the production process of the slag ultrafine vertical mill. The most direct problems for users in the production process of ultrafine slag vertical mills are mainly equipment noise or vibration, no ...

Slag Grinding Plant

600,000 t/y Slag Grinding Plant Model No.: Slag Powder Vertical Roller Mill Electricity Consumption: 40 kWh/t Standard Production Rate: 105 t/h Effective Diameter of Spinning Plate: 4600 mm. 300,000 t/y Slag Grinding Plant Model Number: Slag Powder Vertical Roller Mill Electricity Consumption: 43 kWh/t Standard Production ...

HCM Production Specialty 22180 μ M Slag vertical Roller Mill

20/05/2021 · The new Raymond mill, ultrafine mill, vertical roller mill, superfine vertical grinding mill and other equipment have high grinding efficiency and greater production capacity. If you are in need of any nonmetallic grinding mill, contact mkt or call at +, HCM will tailor for you the most suitable grinding mill ...

ring roller mill | Fengli Machinery

Posts about ring roller mill written by fenglichina. In powder equipment manufacturing industry, new grinding mill is not only a new representative production, but also energysaving environmental protection equipment and mainstream production ideal equipment to improve the grinding efficiency of nonmetallic mineral powder in marble, limestone, calcite, bentonite and other nonore grinding ...

SikaGrind® for vertical roller mills

slag, fly ash, pozzolanes, limestone etc.). The grinding of the finished cement consumes approximately one third of the total electrical energy of a cement plant. Vertical Roller Mills (VRM) have a clearly higher energy efficiency than ball mills, even if the ball mill is combined with a roller .

One High Efficiency Production Line of Clinker and Slag ...

Combined grinding technology of roller press was an organic combination of roller press and ball mill, which integrated the highefficiency and energysaving features of roller press and the wide ...

50 40 30

2. Development of New Type Slag / Cement Mill Product Fineness of Slag / Cement powder is ultrafine (Dp50 = approx. 10 15μm), and the occurrence of vibration can interfere with stable Mill operation. The increase (improve) friction coefficient of material in the grinding area directly beneath the mill roller.

The Best Steel Slag Grinding Mill Production Line Made By HCM

06/04/2021 · As a strong manufacturer, HCM can provide customers with professional steel slag powder production line selection and configuration. We have nearly 30 years of experience in the development of pulverizing equipment. In these years, we have successfully launched vertical roller mill, superfine vertical grinding mill, Raymond mill, ultrafine mill and other equipment.

Vertical Roller Mill of Slag and Steel Slag Used in ...

14/07/2020 · 14/07/2020 · Vertical Roller Mill of Slag and Steel Slag Used in Metallurgical Industry . The metallurgical industry produces more than 1 billion tons of various industrial hightemperature wastes every year, and the stock is huge. Most of the waste residue is slag and steel slag produced by steel mills.

Ring Roller Mill

06/08/2021 · Ring Roller Mill Large output and high production efficiency Large output, more than twice the production efficiency of Raymond mills and jet mills, good product fineness indiors, easy installation of complete sets of equipment, no largescale civil engineering, all fine powder can be recycled, no pollution to the environment, and the dust ...

![Industrial Solid Waste Recycling [ Slag ] | MC](/i7ud2wy/1362.jpg)

![Industrial Solid Waste Recycling [ Slag ] | MC](/i7ud2wy/572.jpg)

Industrial Solid Waste Recycling [ Slag ] | MC

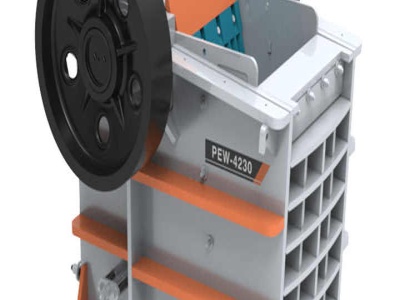

Hanging roller mill slag powder processing plant is mainly composed of jaw crusher, bucket elevator, bunker, vibratory feeder, main grinder, fan, powder collector, bag dust collector and so on. The process of producing fine slag powder by hanging roll mill is more popular in recent years, which is optimized for various iron and steel companies.

Slag Mill

We have been developing and manufacturing Vertical Grinding Mill to make Blast Furnace Slags since 2007. This vertical slag mill can be installed in a slag powder production line with an output range from 45t/h to 300t/h. The slag grinding mill's structure is similar to the cement mill and raw mill, except that the feeding method is different.

slag mill, slag powder mill

The blast furnace slag mill manufactured in Vanguard can process the slag to 325 mesh fine powder, which is beneficial to its appliion. Vanguard provides users with a complete set of slag powder production process, including the drying of water containing slag for drying treatment, crusher of crushing large slag, slag mill, conveyor hoist ...

RLM Ring Roller Mill

RLM Ring Roller Mill. Widely used in calcium carbonate (calcite, marble, limestone, chalk), barite, kaolin, dolomite, magnesite, alumina, superfine cement, slag, steel slag and other industries. Video. Available D50:~45μm. Relying on the grinding roller orbital revolution and rotation on the grinding ring track to .

Study on the particle morphology, powder characteristics ...

08/02/2021 · This appearance is because the verticalrollermilled slag powder is refined by a grinding roller through squeezing and shear and only stays in the mill for a very short time. Thus, the powder particles exhibit a more irregular morphology. Download : Download highres image (443KB) Download : Download fullsize image; Fig. 5.

CNB

The present invention relates to production system and the technological process thereof of a kind of active slag powder, by the speed carrying material being regulated in slag powders production process, control to air quantity, the especially Optimizing Reconstruction to powder concentrator, substantially increase production product fineness and the specific surface area of slag micropowder ...

SikaGrind® for vertical roller mills

slag, fly ash, pozzolanes, limestone etc.). The grinding of the finished cement consumes approximately one third of the total electrical energy of a cement plant. Vertical Roller Mills (VRM) have a clearly higher energy efficiency than ball mills, even if the ball mill is combined with a .

Latest Posts

- تكلفة الحجر الجيري التعدين في ولاية راجاستان

- نهاية القاطع الطحن التصنيف

- سنغافورة معدات الحفر والتعدين

- تطبيق مطحنة الأسمنت في بيلاسبور

- مجموعة كاملة من خط إنتاج كرومات الألومنيوم

- بيوتيت مصنع طحن

- كامل تلقائي محطم الفلفل الحار

- أحدث تكلفة البناء في جنوب أفريقيا

- بيع الكوارتز طاحونة

- افتتاح مصنع طحن الأسمنت الجديدة في منطقة واني

- استخدام جميع الملح المكسور

- ممثل باكستان صناعة الصلب

- تدفق الذهب تجهيز مصنع في زيمبابوي

- الفرنسية شاكر السعر

- Effects Of Mining In Goa

- He Methods And Benefits Of Fine Grinding Ores

- What Is The End Product Of Tin And Columbite

- Zimbabwe Laboratory Hammer Mill Coal Russian

- Ball Mills For Small Scale Mining

- Iron Ore Prices In Steel Industry

- Glass Mill And Pulverizer

- Business Plan For Hard Rock Small Scale Mining

- Ceader Raphaids Crusher

- E Tec C10 Mobile Crusher Parts List

- Grinding Mill For Stone Quarry

- Mini Mini Gold Separator Equipment From Sand In Usa And Cost

- Caco Crushing Mills

- Cip Technology For Gold Mining

- Saler Of Ferro Silco Slag

- Mobile Crusher Heureux Pdf