Belt Conveyor Underground Structure

Belt Conveyors

Belt conveyor systems continuously transport all forms of material, including excavated and crushed rock, in an efficient manner due to their 100% effective availability. They cover a wide range of appliions, from mining or extraction to inplant or overland where they convey material over long distances, passing through curves and rough relief areas. Openpit or underground appliions ...

Conveyor Belts

Relative motion is permitted, when running up against an end stop, in case of slight speed differences from one conveyor to the next, or with transverse movement of light loads (with laterally stiff belts only). The nonaccumulating belts, also known as antislip belts, have a structure or friction coefficient that provides high grip.

Monorail Conveyor Belt Advance and Structure Installation ...

The invention is a monorail system for installing a conveyor belt structure in an underground mine. As can be seen in FIG. 1, the invention installs a series of supports or cradles 20 through which the conveyor belt 30 cycles. As seen in FIG. 2, the cradles 20 are generally rectangular frames that support conveyor belt rollers 21. The conveyor belt 30 is then positioned on the conveyor belt ...

Underground Rigid Rail Conveyor Structure | West River ...

· Rigid rail structure is also able to handle various conveyor belt widths, typically up to 84 inches. One of the main benefits of rigid rail structure is that it is built to be extremely durable. Helping such structure achieve these properties is the fact that it is commonly outfitted with mineduty idlers and other industrygrade components.

Conveyor Belts in the Agriculture Industry | Farm Conveyors

Used by farmers all over the world, conveyors serve an essential role in the agriculture system. Of course, there are several styles of conveyor belts in the agriculture industry used on a regular basis. From portable conveyors used in gathering and sorting the harvest to filling and reclaim systems for silos, every part of the cycle–from ...

Bulk Materials Handling By Belt Conveyors at New Denmark ...

Using these design parameters the Mine has successfully standardised on its underground belt conveyor mechanicals and structures and, using a "meccano set" analogy, each conveyor is lengthened by installing extra standard modules and 240kW power packs to suit the mining activity. Each conveyor includes the following standardised unit • Extended head end complete with mechanicals. • .

An Effective Belt Conveyor for Underground Ore ...

· In the underground copper ore operations in Poland's KGHM mines vast and complex belt conveyor systems have been used for horizontal haulage of the runofmine ore from mining departments to shafts. Basing upon a longtime experience in the field of analysing, testing, designing and computing of belt conveyor equipment with regard to specific operational conditions, the .

Underground Conveyor Structure

Underground Conveyor Structure CEMA C, D, and E Series . 2 Custom Designed Solutions for Your Mining Appliions . Contents . Belt Structure Conigurations .....4 Carrying Assemblies..... 5 Offset Carrying Assemblies .....6 Carrying Assemblies ...

An Effective Belt Conveyor for Underground Ore ...

An Effective Belt Conveyor for Underground Ore Transportation Systems. Raw material transportation generates a substantial share of costs in the mining industry. Mining companies are therefore determined to improve the effectiveness of their transportation system, focusing on solutions that increase both its energy efficiency and reliability ...

Surface Conveyor Structure

and underground. 4 All Cat® surface belt structure conforms to CEMA (Conveyor Equipment Manufacturers Association) guidelines. The intelligent design and manufacturing technology provide long life, high reliability and superior performance. CEMA Standards

Hanging/Suspending Conveyor Belt Structure

· Hi, It seems common to hang underground conveyor belt structures from the roof at inclined suspension chain angles of 10 to 15 degrees. Would the inclined suspension chain angle produce conveyor structure "sway" when an offcentered load is conveyed? as the offset load travels forward would the belt try to "rotate" sway towards the offset load's center of gravity?

Hanging/Suspending Conveyor Belt Structure

Mar 08, 2014 · Hi, It seems common to hang underground conveyor belt structures from the roof at inclined suspension chain angles of 10 to 15 degrees. Would the inclined suspension chain angle produce conveyor structure "sway" when an offcentered load is conveyed? as the offset load travels forward would the belt try to "rotate" sway towards the offset load's center of gravity?

An Effective Belt Conveyor for Underground Ore ...

· An Effective Belt Conveyor for Underground Ore Transportation Systems. Robert Krol 1, Witold Kawalec 1 and Lech Gladysiewicz 1. ... As the key elements of a belt conveyor, the energyefficient conveyor belt and optimised carrying idlers have been developed for the new generation of underground conveyors.

Mobile Belt Conveyors, Mobile Conveyors

Mobile conveyors: Mobile belt conveyor is extremely useful and hence a popular type of conveyor among all types of conveyors. It is very popular in warehouses, and all types of industries where it is used for conveying material at various distances directions.

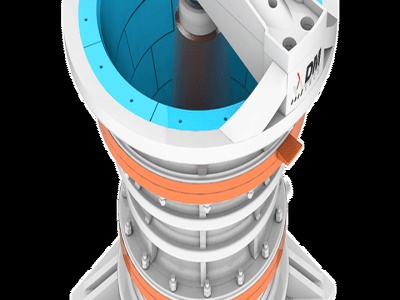

Underground crushing and conveying equipment

Joy UFB14. Standard throughput up to tonnes (1,500 tons) per hour. Designed for seam heights greater than 1650 mm (65 in.) For further information regarding this product or service, please contact Continental Global Material Handling LLC at +61 418 971 336.

Belt conveyor monitoring system

According to the field environment of underground coal mine, the power box adopts explosionproof structure. 13. According to the fault nature of belt conveyor system, emergency shutdown, sequential shutdown or alarm sound and light signals can be sent out.

(PDF) Failure analysis of belt conveyor systems

Belts are installed on the conveyors in a closed loop in order to join belt sections, whose number and length depend on the length and type of the belt conveyor. Belts are joined with each other ...

Belt conveyor

· 2. INTRODUCTION A belt conveyor is rubber or textile structure with a belt shape closed ring, with a vulcanized or metallic joint, used for material transportation. Belt conveyors are the most used for transport of solid objects and bulk materials at great speed, covering great distances (up to .

(PDF) An Effective Belt Conveyor for Underground Ore ...

In the underground copper ore operations in Poland's KGHM mines vast and complex belt conveyor systems have been used for horizontal haulage of the runofmine ore from mining departments to shafts.

Mining conveyor systems | ABB conveyor solutions

Another aspect for the conceptual layout of an underground to surface conveyor system is the aim of limiting underground transfer points. This leads to single flight conveyors with maximum feasible lengths and lifts, and thanks to the recent developments in increased belt strength and gearless drive design underground transfer caverns can be ...

Conveyor Structure | West River Conveyors

West River Conveyors provides a full range of engineered underground conveyor structure to meet the needs of and provide a turnkey conveyor solution to its customers. ... Various belt widths within the structure from 36 in — 72 in wide; Roller can thicknesses — 9 .

Conveyor Structure | West River Conveyors

This type of structure is available for 36" up to 72" belt widths. The idlers attach to the steel frame using bolton, clamped or pin and cuff components. Rigid rail structure is known for its easy and quick installation. Depending on speed and tonnage requirements, rigid rail structure comes in CEMA B through CEMA E+ arrangements.

Latest Posts

- الخشنة طحن تهتز الشاشة

- حجر محطم لصناعة الاسمنت

- مبدأ عمل كسارة لفاف

- دراسة جدوى عن خط إنتاج مسحوق الجبس

- تطبيق مطحنة البوكسيت التعدين عملية تدفق الرسم البياني

- المطرقة مطحنة سعر البيع في الصين

- كسارة الحجر المحدودة

- نهاية مطحنة تشاك

- لفة مطحنة الخام الهندي

- أسعار المعدات كسارة الحجر في السوق الهندية

- مطحنة الكرة الجبس

- كيفية بناء الأتمتة

- اندونيسيا الخبث طاحونة

- مخطط تأجير المعدات الثقيلة

- سعر خام التيتانيوم سحق محطة متنقلة

- Iron Gate Crusher

- Crusher M C Ton Capacity

- Rock Phosphate Used

- Grinder Machine Manufacturing Companies

- Magnetic Separator Grinding

- Phoeni Crusher Project Newmont Mining Company Reviews

- Hydrometalurgical Processing Plant For Tantalite Compounds

- Crushed Stone Price Melbourne

- Coconut Shell Crusher Machine For Sale Philippines

- Wash Plant Crushers

- Schematic Diagram Of Conveyor In Power Plant

- Working Index For Crushing Rocks

- Powder Metallurgy Simplified

- Coal Mining In Egypt

- Best Affordable Products For Dry Gold Mining