Ball Mill High Effictive Metal Ball Mill Machine

TECHNICAL NOTES 8 GRINDING R. P. King

but values as high as 90% are sometimes used. A crucial parameter that defines the performance of a mill is the energy consumption. The power supplied to the mill is used primarily to lift the load (medium and charge). Additional power is required to keep the mill rotating. Power drawn by ball, semiautogenous and autogenous mills A simplified picture of the mill load is shown in Figure ...

Laboratory Ball Mills, Planetary Ball Mill, High Energy ...

Planetary ball mills are smaller than common ball mills and mainly used in laboratories for grinding sample material down to very small sizes. A planetary ball mill consists of at least one grinding jar which is arranged eccentrically on a socalled sun wheel. The direction of movement of the sun wheel is opposite to that of the grinding jars (ratio: 1:2 or 1:1 or else). The grinding balls ...

Ball Mills | Industry Grinder for Mineral ...

【Ball Mill Working Principle】 High energy ball milling is a type of powder grinding mill used to grind ores and other materials to 25 mesh or extremely fine powders, mainly used in the mineral processing industry, both in open or closed circuits. Ball milling is a grinding method that reduces the product into a controlled final grind and a uniform size, usually, manganese, iron, steel ...

Ball Mill: Operating principles, components, Uses ...

· A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis. The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill size. The large balls tend to break down the coarse ...

Ball Mills –

Ball Mills are the most effective laboratory mills for rapid batchwise comminution of mediumhard, soft, brittle, fibrous, temperaturesensitive and moist samples down to the finest particle size. The comminution of the material to be ground takes place through impact and friction between the grinding balls and the inside wall of the grinding bowl respectively the mortar.

ball mill high effictive grinding ball mill

The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming . Ball Mills Glen Mills, Inc. The extremely high centrifugal forces of planetary ball mills result in very high ...

Rod Mills

· The mill heads are insured against breakage due to the high tensile strength of cast steel as compared to that of the cast iron head found on the ordinary rod mill. Trunnion Bearings are made of highgrade nickel babbitt, dovetailed into the casting. Ball and socket bearings can be furnished if desired. Buy a Rod Mill. Head and shell liners for ...

Ball Mill High Effictive Planetary Ball Milling

Ball mill sample grinding machine the ball mill sample grinding machine is a small type vertical planetary ball mill, with 4 working stations, each volume is 100ml. it is used for the quick, high efficient grinding, mixing, homogenizing of lab samples. Read More; 100 Ml Agate High Energy Planetary Ball Mill Grinding Jar

Ball Mill

Milling; Ball Mills; Ball mills are among the most variable and effective tools when it comes to size reduction of hard, brittle or fibrous materials. The variety of grinding modes, usable volumes and available grinding tool materials make ball mills the perfect match for a vast range of appliions. NEW Mixer Mill MM 500 control. Feed material: hard, mediumhard, soft, brittle, elastic ...

Ball mill, mineral ball mill, gold ball mill, ball mill ...

Ball mill grinding machine is a kind of horizontal drumtype grinding mill with external gear and double bins. Materials goes evenly through quill shaft in feeding device into the first bin, which has ladder lining or ripple lining with steel balls in different balls are taken to a certain height by centrifugal force from drum rotation and then fall. Thus it will give a ...

ball mill high effictive grinding ball mill

Ball mill steel balls cylpebs grinding balls high chrome . The interplay between these forces produces the high and very effective degree of size reduction of the planetary ball mill History The general idea behind the ball mill is an ancient one but it was not until the industrial revolution and the invention of steam power that an effective ball milling machine could be built It is reported

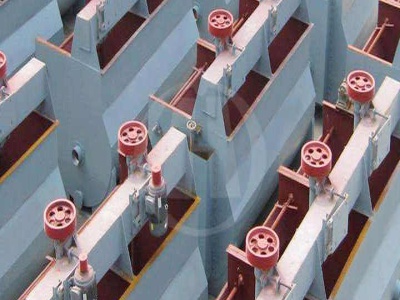

Manufacturer of Roller Grinding Mill Plant | Ball Mill ...

ROLLER GRINDING MILL PLANT. The Malwiya Engineering Works is manufacturing with use of high quality and noncorrosive metal along with cuttingedge technology, our Roller Grinding Mill which is highly in demand. We are a reputed Manufacturer, Exporter and Supplier of Roller Grinding Mill from Udaipur (Raj.)India.

ball mill high effictive metal ball mill machine

Ball Mill High Effictive Metal Ball Mill Machine. Key Factors in Successful Hard Milling : MoldMaking . To efficiently carry out high speed milling strategies, a machine must have a ball mill was 10 microns; now of hardened steel milling. Tooling, machine tool . Get Price. Building a Ball Mill ABYMC. Building a Ball Mill Building the Machine. I built a ball mill from looking at a picture of ...

Lab Ball Mills

Tel: . Fax: . Mobile: . Email1: mills Lab Ball Mills. Mill Jars/Pots/Tanks. Ball Mill Medias. Lab Powder Equipment. Lab Glove Box / Operation Box.

super effictive zirconia ball mill grinding media price ...

grinding mill ball mill cement machine part tungsen carbide. Tungsten carbide grinding bowls and mortar is the highest density grinding tools for laboratory grinding mill ball mill machine power grinder ball mill crusher hardness and strengthness can meet the appliion of crushing and refining for most majority of metal powder especially those hard and super

Grinding Mills

Nelson Machinery sells new used grinding mills including ball mills, SAG mills, tower mills, Raymond roller mills. Equip yourself with the gold standard

Industrial Ball Mills: Steel Ball Mills and Lined Ball ...

Steel Ball Mills Lined Ball Mills. Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800's. The basic construction of a ball mill is a cylindrical container with journals at its axis. The cylinder is filled with grinding media (ceramic or metallic balls .

Ball mill

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls.

High Efficiency vs. High Feed Milling: Which is More ...

· Highefficiency milling has gotten a lot of attention in recent years as a way to substantially increase metal removal rates with solid carbide end mills on almost any kind of milling machine. With small stepovers, but faster feed rates and deeper depths of cut, this "constant chip load" cutting strategy can dramatically increase roughing efficiency compared to conventional machining.

Latest Posts

- لفة مطحنة تصميم التبريد

- كتاب عن كسارة الحجر

- الصين معدات البناء كسارة صغيرة

- شبكة معدنية تهتز الشاشة

- مجموعة طحن

- استبدال الرمل مع الرمل المكسور

- التوربينات طبل غربال تعدين الذهب

- مواصفات كسارات الفك الهندي

- PCZ سلسلة كسارة المطرقة الثقيلة

- شراء معدات سحق المحمول

- المملكة العربية السعودية جازان الأسفلت المورد

- تستخدم آلات إنتاج الزجاج للبيع

- بيع كسارة الفك جزء لكل تريليون

- جنوب أفريقيا موبايل شاكر

- Lagos Stone Crusher Manufacturer And Supplier From China

- Crushing Sale Self Contained Rockcrusher

- New Projects Of Stone Crusher Conveyor

- Global Conveyor Belt

- Coal Crusher Manufacturers Yorkshire

- Conveyor Belt Control For Bottling Plant

- Crusher Output Size 40mm

- Maintenance Steps In Industrial Pit

- Chile Govt Schemes For Setting Up Pulse Mill

- A Crushing Machine Sam Crushers

- Processing Tar Sand Natural Gas

- Zimbabwe Government Gazette 8th March New Mining Claims Prices

- Coal Grinding Ball Mill Sale From Germany

- Open Closed Cost Of Coal Mines

- Mill Intermittent Type Mill

- Gyratory Jaw Crusher Manufacturer Russia Medical