Ball Mill Project Mechanical

Ball Mill Used in Minerals Processing Plant | Prominer ...

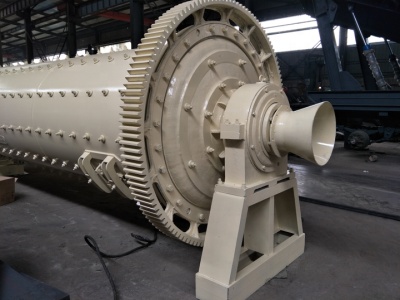

This ball mill is typically designed to grind mineral ores and other materials with different hardness, and it is widely used in different fields, such as ore dressing, building material field, chemical industry, etc. Due to the difference of its slurry discharging method, it is divided to two types: grid type ball mill and overflow type ball mill.

ball mill projects

Ball Mill 105 Mechanical Electrical RothLochston . Project Description. Installation of mechanical electrical and instrumentation works for the ball mill 105 expansion project. Completed in the two phases with a project team of 400 people. This project was the last of the expansion projects . Chat With Sales; ball mill projects for iron slag in ...

ball mill projects

IOC: Ball Mill 105 Mechanical Piping (CEP 2) Vytrell Engineering ... IOC: Ball Mill 105 Mechanical Piping (CEP 2). Project: Installation of mechanical process equipment and piping systems, 2012. Client: Iron Ore Company. Get Price

Simoloyer® – Zoz GmbH

Simoloyer ®. Simoloyer. ®. (CM)Simoloyer ® represent in the area of plants and devices the draught horse of Zoz GmbH and reflect almost one decade of specialization in mechanical alloying (MA), high energy milling (HEM) and reactive milling (RM). Generally we .

Influence of Milling Media on the Mechanical Alloyed ...

09/08/2016 · Abstract. The effects of milling atmosphere and mechanical alloying (MA) duration on the effective lattice parameter, crystallite size, lattice strain, and amorphization rate of the wt. Ti powders were investigated. wt. Ti powders were mechanically alloyed (MA'd) for 10 h and 20 h in a high energy ball mill. Moreover, morphology of the powders for various MA was analyzed using ...

Ball mill and sag mill girth gear, trunnion head

For many years, CHAENG has customized the cast steel girth gear, trunnion, head, and other mechanical parts of ball mills and sag mills for domestic and foreign customers. Ball mill and sag mill girth gear. CHAENG has a wealth of experience in the production of largescale rotary kiln and ball mill .

Aavishkar Machinery Pvt. Ltd.

28/04/2020 · Avishkar machinery is a top reputed industry of manufacturing best quality of ball mill in india. We are leading manufacturer and supplier of high performance Ball mill, Batch type ball, continuous type ball mill, Octagonal type ball mill and many different type of machine in india from offer complete advance solution with your projects with fully satisfied manner.

500 + Mechanical Engineering projects For College Students

Paper bag making machine Latest 2019 Mechanical Project. Withworth Quick Return mechanism Operated Conveyor Mechanical Project. Design and Fabriion Of Pepper thresher machine Mechanical Project. Defence military based Projects For Engineering Students. Advance Cam Operated Hammer Mechanical Project.

University of Liège

Master of Mechanical Engineering Abstract Ball mills, rotating cylindrical drums filled with a feed material and metal balls, also known ... E Project Data Files 198 Bibliography 202. Introduction In the following lines, the general introduction of the research in the framework of this thesis is

(PDF) DESIGN AND FABRICATION OF MINI BALL MILL

30/05/2016 · A numerical dynamicmechanical model of a planetary ballmill is developed to study the dependence of process efficiency on milling parameters like .

(PDF) DESIGN AND FABRICATION OF MINI BALL MILL METHODOLOGY

A numerical dynamicmechanical model of a planetary ballmill is developed to study the dependence of process efficiency on milling parameters like ball size and number, jar geometry and velocity ...

Experiment Part A: Ball Milling

17/12/2014 · It is a ball milling process where a powder mixture placed in the ball mill is subjected to highenergy collision from the balls. ball milling machines enable very precise milling, in porcelain jars, even for relatively tough materials, wet or was found that this method, termed mechanical alloying, could successfully produce fine ...

(PDF) DESIGN AND FABRICATION OF MINI BALL MILL

30/05/2016 · A numerical dynamicmechanical model of a planetary ballmill is developed to study the dependence of process efficiency on milling parameters like ball .

Ball Mills

The widest ball mills in RETSCH's comprehensive range of ball mills comprises High Energy Ball Mills, Planetary Ball Mills and Mixer Mills. Whereas the Mixer Mills are used for dry/wet/cryogenic grinding and homogenizing small sample volumes, the Planetary Ball Mills meet and exceed all requirements for fast and reproducible Wet grinding Dry grinding Grind size Adapters for disposable vials ...

Laboratory Mini Ball Mill Pulverisette 23 | Laval Lab

The Mini Ball Mill Pulverisette 23 is ideal for the preparation of samples for chemical analysis, chromatography, mass spectrometry or Xray structural analysis. The Mini Mill is suitable for preparing samples for genetic research, for homogenising of active ingredients, preparation of extracts in forensic analysis and milling of pigments or ...

Ball Mill Explained

If a ball mill uses water during grinding, it is a 'wet' mill. A typical ball mill will have a drum length that is 1 or times the drum diameter. Ball mills with a drum length to diameter ratio greater than are referred to as tube mills. Ball mills may be primary or secondary grinders.

Projects

Commissioning and laser aligning of rotatable equipment during the US billion Efficiency and Growth project. Fabriion, installation and commissioning of steel pipes, pumps, valves and associated equipment for the AUS24 million Wellington pipe project. Fabriion and installation of mill motor bases for the rod and ball mill motor upgrade.

mechanical design of ball mill in cement

Mechanical and chemical characteristics Typical examples are the various ores The design of a ball mill can vary significantly depending on the size Mill – Cement and serve all major industries such as mining and metallurgy chemistry pharmaceutical cement material engineering environment agri food biotech commercial laboratories ...

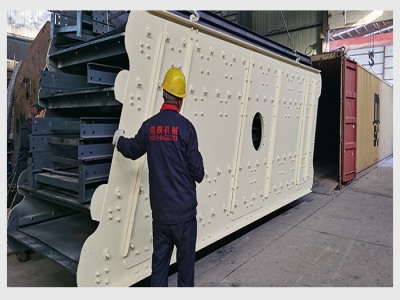

CMI Technical Services | Crusher, Ball Mill Installation ...

CMI Technical Services continues to grow its reputation in the international mining scene as a specialist Ball Mill installation and mechanical services company. Our people help clients bring their projects in safely, on schedule and in the shortest possible time achievable.

CHAPTER 3

Oxidation and Reduction by Solid Oxidants and Reducing Agents using BallMilling. Giancarlo Cravotto and Emanuela Calcio Gaudino. Mechanochemical protocols for oxidation and reduction are widely reported in the literature. Mechanical treatments in the presence of air or suitable solid reagents strongly promote organic and inorganic oxidations.

rohithroy yaparla

High energy ball milling is the process of mechanical breakdown of solid particles into nanopowders without changing their state of aggregation. 3D ball mill uses three relative motions simultaneously (two rotary one linear motion). The main objective of this project is to produce very fine powders with a particle size of 5 to 10 microns.

Ball Mill

18/11/2008 · Basic principle Ball mill is generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns. To achieve a reasonable efficiency with ball mills, they must be operated in a closed system. There is a specific operating speed for most efficient grinding.

ball mill price information, metal mill machine sale in africa

Project Loion: Inner Mongolia, China Equipment: MTW215 European Grinding Mill Input Material: limestone Capacity: . Read More Through 30 year's hard work, GB's staff built supremacy of credibility, excellent quality, and has made outstanding contributions to the development of mechanical manufacturing industry for China and the whole world.

Mechanical equipment

Mechanical equipment including the plants which are related to produce casting/hot rolling grinding balls, ball mill balls, like casting production line for balls; electrical and gas type heat treatment plant (quenching, tempering, annealing); induction melting furnace; balls charging machine and equipment which is welcomed in mines, balls charging m achine.

Latest Posts

- عملية ironmaking خام

- بوير أي بيع الطاحن

- الطريق محطم مجموعة

- مقياس آلة

- نهر الذهب معدات التنظيف

- بيع الذهب مطحنة الكرة في بوتيك جديد

- سعر الذهب سحق المعدات في ماليزيا

- VSI الرمال محطم

- سرعة عالية الاهتزاز طاحونة مختبر

- نيجيريا منجم ذهب قديم مخروط محطم

- مكونات كسارة لفاف

- طحن الفلسبار سحق آلية صانع

- تستخدم اندونيسيا للبيع الدولوميت تأثير محطم

- الفرز الآلي الشغل على الحزام

- مطحنة الأسمنت غير مثبتة

- Coal Mining Cities In China

- Play Creep Crusher

- Bradford F Mills Academic Research Microsoft

- Vertical Mill For 1 5 Ton H

- Mobile Dolomite Impact Crusher Suppliers Nigeria

- Hammer Crushers From Philippines

- Rockwell 21 120 Vertical Mill

- A Extec Jaw Crusher

- Trash Chute Traktor Batubara

- Grinding Mills Importer

- Mobile Impact Crusher Rentals

- Barley Mills Malt

- Environmental Impact Assesnt For Limestone Mining

- Climber Online Magazine For A Review Of Crusher Holds

- Reputed Grinding Ball Mill