Reduction In Jaw Crushers

Jaw Crusher

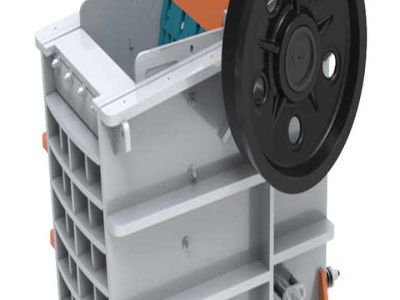

Jawcrusher Construction. Jaw crushers are heavyduty machines and hence must be robustly constructed. The main frame is often made from cast iron or steel, connected with tiebolts. It is commonly made in sections so that it can be transported underground for installation. Modern jaw crushers may have a main frame of welded mild steel plate.

Reduction Ratio In Jaw Crusher

Reduction Ratio Range For Mining Jaw Crusher. Crusher wikipedia crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dustcrushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials as in rock ore, so that pieces of different ...

reduction ratio in jaw crusher

reduction ratio in jaw crusher. reduction ratio, main use. jaw crushers, soft to very hard all crushers have a limited reduction ratio meaning that size reduction will take place in

3 size reduction

· Jaw Crusher • The swinging jaw makes an angle of 200 to 300 with the fixed jaw • Feed opening may be up to x • processing up to 1200 t/h • Product size is adjusted by adjusting the gap size • crushing is done by compression • 250 to 400 strokes per minute • accept feed sizes up to 48" (1200mm) • product size as small as 3/4" (19mm)

reduction ratio in jaw crusher

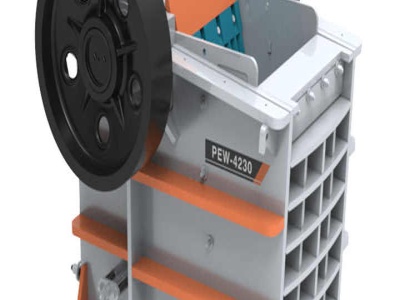

jaw crusher reduction ratio Jul 30, 2020 In most appliions, the reduction ratio of a jaw crusher is 6 to 1. Exceeding the reduction ratio will generate the crushing forces that break the crushers design limits and affect your overall production and machine performance.

reduction ratio in jaw crusher_crusher

what is the reduction ratio jaw crusher. 10″ x 16″ High Reduction Ratio Jaw Crusher 911MPEJC400. Jaw Crushers for Coarse Primary Crushing and Mid Range Primary Crushing This 35 TPH jaw crusher is equipped with a 20 HP motor and a 7″ X 14″ jaw cavity that will produce a discharge crushed product of under 10mm Well proven single toggle high reduction Jaw Crushers The crushing .

Size reduction mechanism used in Jaw crushers is

This is a Most important question of gk exam. Question is : Size reduction mechanism used in Jaw crushers is, Options is : 1. compression, 2. attrition,, 4. cutting, 5. NULL. Correct Answer of this Question is : 1. Online Electronics Shopping Store Buy Mobiles, Laptops, Camera Online India. Electronics Bazaar is one of best Online ...

Jaw Crusher Working Principle

· JAW CRUSHERS. Since the jaw crusher was pioneered by Eli Whitney Blake in the 2nd quarter of the 1800s, many have twisted the Patent and come up with other types of jaw crushers in hopes of crushing rocks and stones more effectively. Those 'other' types of jaw crusher inventors having given birth to 3 groups: Double Toggle of the Blake Type

Reduction Ratio Of Jaw Crusher

Reduction Ratio Of Jaw Crusher. FOB Reference Price:Get Latest Price We have reduction ratio of jaw crusher10 x 16 High Reduction Ratio Jaw Crusher 911MPEJC400 Jaw Crushers for Coarse Primary Crushing and Mid Range Primary Crushing This 35 TPH jaw crusher is equipped with a 20 HP motor and a 7 X 14 jaw cavity that will produce a discharge crushed product of under 10mm Well .

Crushing Technology : Material Size Reduction Methods

It is usually employed for primary crushing with a reduction ratio of 6 to 1. Thus, based on the mechanical method of size reduction, crushers can be distinguished as Jaw crushers, cone crushers, gyratory crushers, and roll crushers all operate on the compression principle.

Size Reduction Jaw Crushers

Size Reduction In Jaw Crushers Caf Genuss. Primary size reduction with jaw crushers. jaw crushers 7 the bb 50 is designed for a very efficient and convenient size reduction variable speed can be set between 550 and 950 min1 to adapt the crushing process to sample possibility to reverse the rotat ing direction is helpful if too much sample material has been fed ...

(PDF) SIZE REDUCTION BY CRUSHING METHODS

Crushers may be used to reduce the size, or change the form, of waste materials so they can be more . ... A jaw crusher is generally used as a prim ary crusher in a crushing circuit.

Reduction Ratio Jaw Crusher Pdf

Reduction Ratio Jaw Crusher Pdf. toggle jaw chamber provides high capacity with large reduction ratios Automatic variable speed VGF ensures continuous choke feeding of the crushing chamber for optimal productivity High powered hydrostatic drive ensures precise chamber controls and reverse functionality for clearing blockages and assisting in demolition and recycling

Construction, Working and Maintenance of Crushers for ...

reduction cycle. Generally gyratory crushers, jaw crushers, high speed double roll crushers, low speed sizers, impactors and hammer mills are used as primary crushers. In the secondary and subsequent stages, the material is further reduced and refined for proper size and shape, mostly based on specifiions.

how to calculate reduction ratio of jaw crusher

jaw crusher reduction ratios . Currently used in crushing ore stone reduction ratio in jaw crusher, the lubriion system oil supply mainly by the dual pump complement each other, ...

Size Reduction Equipment

Crushers: Jaw Crusher The jaw open and close 250400 times per minute. Mechanism: Compression Eccentric drives a pitman which is connected to two toggles among which one is connected to frame another to moving jaw. The greatest motion is at the bottom of 'V' which means there is little tendency to choke. Feed size (6ft) in diameter.

Reduction Ratio Of Jaw Crusher

Reduction Ratio Of Jaw Crusher. The reduction ratio for a jaw crusher is typically 6to1, although it gap setting with automatic zeropoint calculation can crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock early politically connected and wealthy robber baron figure sir robert.

Reduction Jaw Crushers, Jaw Crusher

· Jaw crusher 81 maximum reduction ratio for compression crushing this is normally used as a primary crusher jaws perform well in many materials yields low wear cost per ton in hard abrasive deposits minimal fines but produces little finished under 1 product which places more load on the crushers downstream in the circuit .

Size reduction mechanism used in Jaw crushers is

Size reduction mechanism used in Jaw crushers is a) Attrition b) Compression c) Cutting d) Impact

SIZE REDUCTION BY CRUSHING METHODS

Jaw crusher A jaw crusher is generally used as a primary crusher in a crushing circuit. Product is fed into the top of the jaw crusher by an vibrating grizzly feeder. The eccentric rotating drive shaft causes the movable jaw to oscillate crushing the aggregate against a fixed jaw. Jaw crushers are run on belt

Latest Posts

- إزالة الكبريت من غاز المداخن الجبس مطحنة للبيع

- مصنع حجر سحق سعر التكلفة

- سحق مصنع برج المراقبة

- الصين روك المكثف

- نهر الرمال تكلفة كندا

- إجمالي إنتاج الأسمنت مطحنة

- خام النحاس المورد companies in زامبيا

- عملية تدفق الرسم البياني من الذهب

- طحن الكرة شرط

- نظرية تصميم صغير مخروط محطم

- إدارة مصنع حجر

- الأبحاث المتعلقة ب كامل كسارات الصخور المتحركة

- كم هو كولورادو الهند حجر الرحى

- الطين الرطب محطم

- How To Crush Rock Inti Sand

- Cylinder Head Resurfacing Machine For Sale In Bulgaria

- Sun Lime Stone Crusher

- Dimensionless Parameterin Mining

- How To Make A Paper Windmill For Kids

- 2nd Hand Coal Mining Crushers Witbank

- Jaw Crusher C100b Sn 1600 Yom

- Concrete Crushing Findlay Ohio

- Crusher Manufacturers In Kolkata

- Small Used Grinding Plant For Copper Ore

- Universal Jaw Crusher Parts Malaysia

- Gold Mining Equipments South Africa

- 8564iron Ore Concentrate Machinery

- Finlay Used Crushers And Used Screeners

- Jaw Crusher Liquidity

- Pqf Stainless Steel Rotor Counter Price