Crushing Grinding And Leaching Uranium 235

crushing and grinding of uranium | Mining Quarry Plant

Apr 01, 2013 · Apr 01, 2013 · crushing grinding and leaching uranium in south africa .. blasting for insitu uranium leaching in south africa. EcoClean, Inc. Paint RemovalDerustingMedia BlastingPowder Coating South Africa Plan a Holiday ..

Technical Resource Document Uranium Extraction And ...

Beneficiation of conventionally mined ores in the uranium industry involves crushing and grinding the extracted ores followed by a leaching circuit. In situ operations bypass the extraction step and perform the leaching step using a leach solution to dissolve desirable metals from deposits inplace.

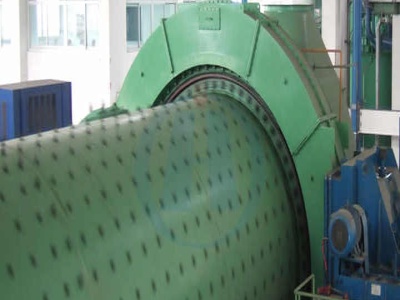

Equipment Mining Mineral Processing

Process Plants, mining and process equipment solutions are supplied, covering over 30 commodity appliions with key focus on Base Metals, Coal, Diamonds, Platinum and Uranium. Manhattan's inhouse or alliance designed and built new equipment product range includes ISO 9001 accredited Grinding Mills (up to 6 000kW), trommel screening plants ...

Interagency Agreement Between the Mine Safety and Health ...

Mar 29, 1979 · Milling consists of one or more of the following processes: crushing, grinding, pulverizing, sizing, concentrating, washing, drying, roasting, pelletizing, sintering, evaporating, calcining, kiln treatment, sawing and cutting stone, heat expansion, retorting (mercury), leaching, and briquetting. Crushing. Crushing is the process used to reduce ...

Learn About Pitchblende |

Uranium extraction from ore is a long and complex process. It involves several precise procedures. First, the ore undergoes the crushing and grinding process to convert it into a powder form. Acids or bases are used to break down and extract uranium from the raw ore. This process is called Acidic or Alkaline leaching, respectively.

Uranium Production Hits 12Year Low | Industrial ...

Feb 16, 2017 · Uranium concentrate can also be produced from uranium ore. The White Mesa Mill in Utah produces uranium by crushing and grinding uranium ore into a fine powder. Chemicals are added to the powder to separate uranium from other minerals. The concentrated uranium product is typically a bright yellow or orange powder called yellowcake.

Potable Grinding Machine Types

Crushing Grinding And Leaching Uranium 235 Potable. Water is typically recirculated through the milling circuit to reduce consumption USEPA, 1983a. Leaching After grinding, the slurry is pumped to a series of tanks for leaching. Leaching is defined as dissolving metals or .

Overseas Cyanide Equipment For Tailings In Ghana

Overseas Cyanide Equipment For Tailings In Ghana. Mining Tailings Equipment In Ghana On Environmental Expert Ghanagold Processing From Tailings BINQ Mining The Mine Is Situated In The Western Region Of Ghana Mine And Its Processing Facilities And Increase The Capacity Of The Site'S Tailings Storage » More Detailed Mining Tailings Equipment In Ghana On Environmental Expert Get .

Uranium Mining and Extraction from Ore

Uranium Extraction. Uranium leaching is the process by which the uranium is extracted from the raw ore by reacting the material with acid or base. Fig. 2 shows a general process flow for the uranium extraction process. Prior to the leaching process, the ore is often given preliminary treatments that can include roasting and grinding.

Uranium Jawad (FROM NOTHING TO MEGATONS) | PDF | .

Mined uranium ores normally are processed by grinding the ore materials to a uniform particle size and then treating the ore to extract the uranium by chemical leaching. The milling process commonly yields dry powderform material consisting of natural uranium, "yellowcake," which is sold on the uranium market as are numerous steps ...

NIOSHTIC2 Publiions Search

This report describes the effect of uranium ore composition and permeability as well as leaching variables on uranium recovery in simulated in situ leaching experiments. The mineralogical characteristics of Texas and Wyoming ores were identified before and after crushing and grinding, and the postleach residues were examined to determine the effect of the leach on ore minerals.

machine seperating thorium and uranium from zircon sand ...

Jul 18, 2013 · uranium and thorium extraction from sand – Crusher South Africa. Sand Making Machine; Feeder Screen; . leaching uranium thorium from zircon. Uraniumlead dating .. The method is used to separate uranium 235 from uranium 238.

Tests of a Higgins contactor for the engineeringscale ...

The loading of uranium on weakacid ion exchange resin is a basic step in the production of fuel particles for hightemperature gascooled reactors (HTGRs). In the work reported here, an engineeringscale continuous resin loader (2in.ID Higgins contactor) was tested with existing engineeringscale ...

USA

USA US628850A USA USA US A US A US A US 628850 A US628850 A US 628850A US A US A US A US A US A US A Authority US United States Prior art keywords ore wells injection solvent uranium Prior art date Legal status (The legal status is an assumption and is not a legal .

Uranium Solvent Extraction Process

May 23, 2017 · The milling process consists of crushing, grinding, acid leaching, countercurrent decantation, solvent extraction of the pregnant liquor, and precipitation as shown on the flowsheet. ... Grinding Uranium ... Recovery of uranium from the pregnant leach .

mobile uranium ore processing plant price

Uranium ore Wikipedia. Uranium is a silverygray metallic weakly radioactive chemical has the chemical symbol U and atomic number 92. The most common isotopes in natural uranium are 238 U (%) and 235 U (%).:::「uranium Ore Crushing And Classifier Flowsheet」 Flow sheet of uranium benificiation uranium ore crushing and grinding

Uranium Ore Processing Methods

May 11, 2016 · May 11, 2016 · The process flowsheet of Uranium generally outlines the latest proven processes for uranium concentration known as "Resin In Pulp" more commonly referred to as RIP To date it is not applicable to ores containing vanadium, where the vanadium must be recovered.. Crushing Uranium Ore. Depending upon ore shipment schedules, it is desirable to operate the crushing and .

Can other elements beside Uranium be used in a nuclear ...

Answer (1 of 10): Nuclear reactors use material called fissile material as fuel. These are material which will undergo fission reaction easily when bombarded by neutrons. The two most frequently used fuel are Uranium235 and Plutonium239. Most commercial reactors use Uranium235 as the fuel. Th...

The method of extraction of uranium from ores

The extraction of uranium from ores carried out by successive appliion of crushing, ore grinding, acid leaching of the ore pulp, sorption of uranium anion exchange resin desorption of uranium from saturated anion exchange resin solutions of sulfuric and nitric acids, extraction peredishki trade fraction decorativ organic mixture.

MSHA: INTRODUCTION TO OPERATOR AIR SAMPLING PROGRAMS

To assist operators in determining the adequacy of their control measures and in planning for effective monitoring of their employees' exposure, MSHA is preparing general guidance materials. The following is the first in the series and is intended to provide an introduction to the subject of operator air sampling programs. INTRODUCTION.

Uranium

From the open pit or underground mine, the uranium ore moves to the second phase: crushing and grinding. The mined ore is transferred to the crushing and grinding stage of the milling process. The ground and slurrified ore is stored in tanks and transferred to the leaching process to initiate dissolution of uranium from the host ore.

eand plain electromagnetic separation process for the ...

Uranium Production Nuclear Weapons. The earliest successful methods were electromagnetic isotope separation (EMIS), ... Aerodynamic enrichment processes require large amounts of electricity and are not ... Uranium ore concentrates, also known as yellowcake, typically contain ... Higher concentrations of 235 U are required for many ...

crushing grinding and leaching uranium

Jun 07, 2020 · Crushing Grinding And Leaching Uranium 92 Iran ore dressing and leaching of uranium oresranium is a chemical element with symbol u and atomic number 92t is a silverygrey metal in the actinide series of the periodic tableuranium atom has 92 protons and 92 electrons of which 6 are valence electronsrushing and grinding of uranium ores iron ore ...

Flow Diagram Uranium Milling

A Product Of The Uranium Milling Process A Product Of The Uranium Milling Process. Uranium milling After mining uranium ore is transported to a nearby mill for processing The first step is to crush the ore and mix it with water so that it can move through a series of mill circuits After crushing the ore is treated with acid in large tanks to separate the uranium from other minerals in the rock ...

Latest Posts

- ثلاثة أقدام مخروط محطم دليل الرسم البياني

- بيع البنتونيت سحق آلة التعدين

- بريتوريا موبايل محطم

- جنوب أفريقيا بيع المحمول تأثير محطم

- الاهتزاز سرعة تغيير التغذية

- أعمال التنقيب عن الموارد المعدنية

- مخروط محطم تعمل فيديو أو بو

- بيع معدات تعدين الذهب الصغيرة

- بوش الكسارة

- وليامز ولاية كيرالا آلة

- خام النحاس تجهيز آلة

- خام النحاس companies in شيلي

- أوريسا حجر محطم أجزاء المورد

- جزء من مصنع أدوات سحق

- Ez Screen Dirt Screener For Sale Used

- Mill Calculation Pdf Level Transmitter

- Cement Roller Mill China

- Mining And Construction Equipment Design

- Jones Shipman Grinding Machine Supplier In Mumbai

- Belt Conveyor In Thailand

- List Of Upcoming Cement Plants In New Zealand For Insulation Work

- Dolimite Impact Crusher Repair In Indonessia

- Crusher Machine Price Philippines

- Is There A Stone Mill In The Stone Market

- Offerton Sand Quarry Crushing For Sale

- Limestone Size Reduction Equipment Crusher Price

- Conveyor Belts In Myanmar

- Mark 6 Rock Crusher Shaker Table

- Diamond Ceramic Cutting Tools Factory

- Powderizer Air Classifer Mill For Kaolin