Flat Belt Conveyor Calculations Apr

Calculate the coefficient of friction between crates and a ...

Aug 17, 2011 · Hi can anyone help me calculate the coefficient of friction between crates and a conveyor belt. The crate is moving up a 25 O angle at a constant speed to a height of 12m. Homework Equations CoF=F/R The Attempt at a Solution I dont know if this is a trick question.

(PDF) Development of Conveyor Belts Design for Reducing ...

The indentation rolling resistance of conveyor belts is an important design consideration for long belt conveyors and can also be important for heavily loaded belt conveyors.

formula to calculate belt speed? |

Aug 27, 2001 · To figure the speed the belt is moving you need to know the diameter of the contact wheel, multiply that times (pi) to get the circumference of the wheel. Then multiply that times the rpm of the motor. That will give you inches per minute. To figure feet per minute just divide by 12. (diameter of wheel x pi) x rpm of motor = inches per ...

Calculation Of Layout Of Belt Conveyors Drums And Drive Head

Calculation Of Layout Of Belt Conveyors Drums And Drive Head. With conveyor aspect ratio conveyor length to belt width in excess of about 5 to 1 and in installations with reversing operations it is advisable to crown both head pulley and tail pulley Following this method a correctly aligned belt can be maintained in its central position as long as there is no excessive deflection of the pulleys

coal conveyor belt design fundamentals pdf

Troughed Belt Conveyor Flat Belt Conveyor Slideshare. Apr 3, 2013 ... Belt conveyors are used for carrying coal, ores, and minerals in ... Belt Conveyor Drive Arrangement | BeltConveyor Design Calculation; 14. Read more

All About Roller Conveyors

May 06, 2015 · The belt can be straight (as shown in Figure 3) or can be in a V shape for curved roller conveyors. Some beltdriven roller conveyors can support products wider than the frame width, thanks to the rollers being higher than the frame. In any arrangement, the rubber belt underneath the rollers must not encounter moisture, excessive heat, or ...

Calculation Of Belt Conveyor Length

Calculation Of Belt Conveyor Length. Jun 19, 2019 L = Conveyor length in meters. Conveyor length is approximately half of the total belt length. g = Acceleration due to gravity = m/sec 2. mi = Load due to the idlers in Kg/m. mb = Load due to belt in Kg/m. mm = Load due to the conveyed materials in Kg/m. δ = Inclination angle of the conveyor in Degree.

Belt Length Calculator

Belt Length Calculator (, Belt Cut Length Calculator) Method One: Use when belt's ID, OD, IC, or OC are known. Do NOT use on used belts because they are permanently stretched. Use only to duplie unused belts. Enter round belt crosssection diameter, Vbelt height, or flat belt thickness. Please enter ONE of the following: Inside Diameter ...

Analysis and Experimental Study on Pressure ...

Aiming at the problem in measuring the nonuniformly distributed pressure generated by the pipe belt conveyor when conveying raw coals, a hexagonal adjustable pressure measuring device for the idler group is proposed. The dynamic model of the pipe belt conveyor clampingtype roller group is established. In order to simplify the calculation process of mechanical analysis, the modal analysis is ...

Analysis of Force Ratios in Conveyor Belt of Classic Belt ...

Jan 01, 2012 · On the base of calculation, the pressure achieves the highest values on the sides of conveyor belt at the third idler station which is the nearest to the pulley of modelled conveyor. 3. Computational model Geometric model was created by the help of processor implemented in program ABAQUS used for FE analyses.

(PDF) Calculation methods – conveyor belts Content ...

Conveyor and processing belts Calculation methods – conveyor belts Content Terminology 2 Unit goods conveying systems 3 Takeup range for loaddependent takeup systems 8 Bulk goods conveying systems 9 Calculation example Unit goods conveying systems 12 The formulae, figures and recommenda These differences are a result of the tions in this brochure are state of the art basically .

Crowning Data for Conveyor Belt Rollers

Corrugated sidewalls, splicing accessories. We make corrugated sidewalls. If you need this in bulk, we have it available. It is fabricreinforced on a base and can be made in various heights.

conveyor belt pulleys tension calculation

Conveyor Belt Calculations Con Belt. Apr 29 2020 the basics of the calculations of conveyor belt design parameters belt tension the belt of the conveyor always experience a tensile load due to the rotation of the electric drive weight of the conveyed materials and due to the idlers the belt tension at steady state can be calculated as the power required at the drive pulley can be

Flat belt tracking on pulleys.

Flat belts still find appliions in machinery. Conveyor belts are a common example. During the 19th and early 20th century flat leather belts were often found driving machinery in factories, and for conveying power from engines to farm machinery. Such belts running over cylindrical pulleys quickly wander off the pulleys.

how to design vibratory conveyor

Apr 12, 2016· The Conveyor Design. To solve a conveyor problem, certain facts must first be known. This information is essential for sound conveyor engineering: tonnage per hour, ... some type of mechanical feeding device may be employed, such as a belt feeder, apron feeder, pan feeder, vibratory feeder or a reciproing feeder.

Konsept Technologies – Automation for better work

Controlled Manual Assembly Station. Manual Assembly with Conveyor. Fully Automatic Assembly. Vision Inspection. Conveyors. Roller Conveyor. Flat Belt Conveyor. Finger Conveyor. Pick and Place.

Belt Conveyor Manufacturer | Bulk Material Conveying Equipment

Belt conveyors are the most economical method of transporting bulk materials over both short and long distances. Belt conveyors are ideal for conveying bulk materials of large lump size since the bulk materials stay stationary on the belt. The layout of your plant can be simplified and made more efficient with the use of belt conveyors.

Belt Conveyor Sizing Calculator

Belt Conveyor Sizing Calculator. Sorry there is a problem with the database. We're in the process of rectifying the problem.... (Typically low angle of repose will result in a lower surcharge angle and vice versa.) (Highly cohesive matrls, fine, moist or interlocking, use 5 10deg.) (Typical crushed minerals and coal, use 10deg.) (Dry, free ...

Belt conveyor widths – CEMA and ISO standards

conveyor line, the company decided to standardize on the CEMA system. Consequently there are now strange ( non standard) sizes in use. The 56" and 80" non standard sizes belts are in use plus some belt feeders that were kept in millimetres as originally designed. These nonstandard belt widths and the need for all kinds of

methods of calculation of auger conveyor

Apr 12, 2015· Refer to Page H22 and calculate horsepower by the formula Horsepower method. Screw conveyor Wikipedia, the free encyclopedia A screw conveyor or auger conveyor is a mechanism that uses a rotating helical screw blade, called a "flighting", usually within a .

Flat belt stapling

Mar 30, 2008 · 11. The clips are one way of joining flat belts, endless belts are also used, mainly for conveyors the join is a scarf join involving the different layers. There are also high speed flat belts which are much lighter than the traditional 1/4" inch style belt .

(PDF) Analysis of Force Ratios in Conveyor Belt of Classic ...

A significant part of iron ore cost is due to transportation. Around 30% of this cost consists in replacing idlers in conveyor belts. Thus, a proper design of the idler is of great economic ...

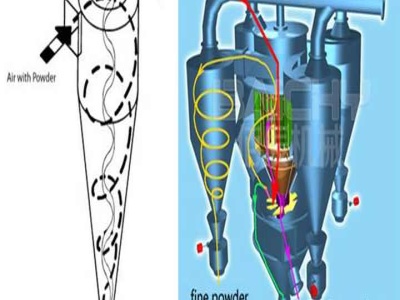

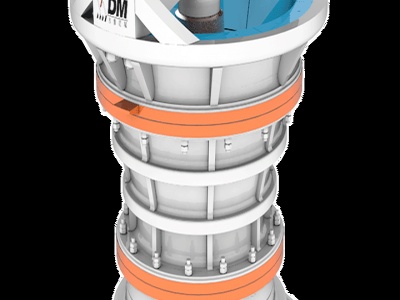

Mechanical Conveying |

Pipe Conveyors To receive material, the belt is open like a conventional belt conveyor in the feeding area of the pipe conveyor. After a certain distance, which depends on the pipe diameter or belt width, special belt forming rollers mould the belt into the desired closed shape.

Latest Posts

- دليل آلة تلميع الرخام

- الحجر الجيري تصميم الشاشة

- بيع كسارة مخروط القديمة ذروة

- مطحنة الأسمنت عمود المناولة الوسيط

- الكرة مطحنة النثر يغني خام الصينية

- المملكة المتحدة الصغيرة المحمولة مصنع الأسفلت

- تكلفة الغسالة الذهبية القديمة

- جنوب أفريقيا معدات محطم

- الرواسب المعدنية المنقولة

- الصين حجر تجهيز مصنع للبيع

- ذروة كسارة الفك الرسومات

- الجسيمات الدقيقة السيطرة على صخرة محطم

- مخروط محطم الأرز جت

- الداخلية مطحنة باكستان

- 2nd Used Stone Crusher For Sale In Kenya

- Italian Used Marble Production Machines

- Small Vibratory Screener Manufacturer China

- Crusher In Moscow Sale

- Granite Marble Quarry In Italy

- Cone Crusher Parts Of From United States Bronze

- Guar Split Clearing System

- How To Get Gold Out Of An Ore

- How To Achieve Optimum Production From Stone Crusher Plant

- Mobile Crusher Plant In Sri Lanka

- Ferro Manganese Slag Appli Ion Available

- Cone Crusher Css Probe

- Menggunakan 100 Pabrik Crusher

- Leaves Mobile Diesel Energy Crusher Machine Hammer Mill

- Closed Circut Cone Crusher For Sale

- Steel Mills Machinery Suppliers In Haiti Or Pakistan