Sand Machine Molding

Leading High Pressure Moulding Sinto Machine line in India

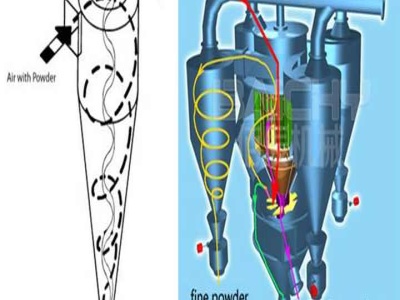

A molding sand mixture, usually green sand or bentonite, is blown into a rectangular steel chamber using compressed air. The molding sand is then squeezed against two patterns, which are on the two ends of the chamber. After squeezing, one of the chamber plates swings open and the opposite plate pushes the finished mold onto a conveyor. Finally, if any cores are there, they are set into the ...

Types of Moulding Sand | Properties of Moulding Sand

In machine moulding no facing sand is used. The system sand is cleaned and has special additives. 8. Core Sand: A sand used for making cores is known as core sand. It is silica sand mixed with core oil (linseed oil, resin, mineral oil) and other binding materials (dextrine, corn flour, sodium silie). It has remarkable compressive strength. 9. Molasses Sand: A sand which carries molasses as ...

Global Green Sand Molding Machine Market Growth ...

Koyo Green Sand Molding Machine Sales (Units), Revenue ( Million), Price (US/Unit) and Gross Margin (E) Table 124. Koyo Main Business Table 125. Koyo Latest Developments Table 126. Küttner Savelli Basic Information, Green Sand Molding Machine Manufacturing Base, Sales Area and Its Competitors Table 127. Küttner Savelli Green Sand Molding Machine Product Offered Table 128. .

What are the precautions for the operation of the sand ...

· · Nowadays, an automatic molding machine is common casting machinery. The correct operation of the sand molding machine will ensure production efficiency and extend the service life of the sand molding machine. In addition, when using the sand molding machine, we must pay attention to its operation points to ensure safe use in work.

Sand Molding

We also have access to 3D sand printing for molds and cores where it's economically feasible versus standard sand and core making. Sand Molding and Coremaking Equipment. 1 – Tinker Omega TOM 550 No Bake mixer which is capable of 1,100lbs of sand a minute 2 – Tinker Omega TOM 350 No Bake mixer which is capable of 550lbs of sand a minute 1 – Tinker Omega No Bake core machine Blow it .

Molding Sand: Constituents, Types and Properties • Bernier ...

System sand. In mechanized foundries where machine molding is employed. System sand is used to fill the whole molding flask. In mechanical sand preparation and handling units, facing sand is not used. The used sand is cleaned and reactivated by the addition of water and special additives. This is known as system sand. Since the whole mold is made of this system sand, the properties such ...

Machine Molding Hand Molding Operations in Casting ...

The hand Moulding method is generally used in institutions whereas Machine Moulding method is used in industrial appliions. 1. Hand Molding Method used in Casting Process [Ramming and Compressing]: Whatever the force required for ramming and compressing of molding sand, if it is obtained from a human hand, then it is called as hand molding.

Different Types of molding sand used in casting process ...

· System sand is used for machine molding to fill the whole flask. Facing sand is not used in this molding because cleaned and has special additives. Molasses sand: This molding sand is also used for core making and small casting of intrie shapes. It contains molasses as its source of binding. Read more: Different types of Foundry tools and equipment. And that is all for this article, where ...

DISAMATIC

DISAMATIC consists of a molding machine and mold transporting molding sand mixture, usually green sand or bentonite, is blown into a rectangular steel chamber using compressed molding sand is then squeezed between two patterns, which are on the two ends of the squeezing, one of the chamber plates swings open and the opposite plate pushes the finished mold .

Moulding Sand: Types and Properties | Metallurgy

In machine moulding no facing sand is used. The system sand is cleaned and has special additives. 8. Core Sand: ADVERTISEMENTS: A sand used for making cores is known as core sand. It is silica sand mixed with core oil (linseed oil, resin, mineral oil) and other binding materials (dextrine, corn flour, sodium silie). It has remarkable compressive strength. 9. Molasses Sand: A sand which ...

Molding Production, Sand Conditioning System, Molding Machines

Molding Production. A mold is produced by using a pattern pressed in prepared sand to form a cavity of a desired shape such that molten metal can be poured into the cavity. The mold cavity needs to retain its shape until the metal has solidified and the casting is removed. Ferroloy uses high quality Green Diamond sand coated with a mixture of ...

Foundry Equipment | Molding Sand Plant | Sree Sakthi ...

· · FOUNDRY EQUIPMENT: SAND MOULDING MACHINE. Free floating anvil for shockless jolting to protect your foundation. Precisely guided pin lift with Hydropneumatics. Hydro – Pneumatic swing in – swing out. Centralised Forced lubriion on every cycle to ensure longer life of wearing parts. Simple pneumatic controls for easy maintenance. Hand wheel operated squeeze plate .

Molding (process)

Molding (American English) or moulding (British and Commonwealth English; see spelling differences) is the process of manufacturing by shaping liquid or pliable raw material using a rigid frame called a mold or matrix. This itself may have been made using a pattern or model of the final object. A mold or mould is a hollowedout block that is filled with a liquid or pliable material such as ...

Adapting a match plate to mount on a sand cast molding machine

· Adapting a match plate to mount on a sand cast molding machine. We sent our match plates to a different vendor for our sand cast aluminum molds. The match plates won't mount directly to the new vendor's mold making machine (Hunter HLM10). The vendor is getting quotes on adapting the match plate by welding on pieces.

Foundry Sand Jolt Squeeze Molding Machine

Foundry Sand Jolt Squeeze Molding Machine. £ 3, £ 3, Joltsqueeze molding machine is designed to make the molding process economical. Simultaneous jolt sqeeze for high mould strength. Designed for easy maintenance, centralized automatic lubriion can be carried out in each cycle.

Sand Molding Equipment

Sand Molding Equipment. Foundry Sand molding machine Includes semi auto type jolt squeeze molding machine and automatic flaskless molding machine. Jolt squeeze molding machine covers small portable type and bigger customized models. Automatic flaskless molding machine covers horizontal parting type and vertical parting type moulding machine.

Fully automatic molding machines|sand casting molding ...

It's a professional manufacturer of fully automatic horizontal parting flaskless molding machine and fully automatic sand casting molding production line. We can provide a professional casting molding solution for foundry enterprises and help them solve molding problems. Improve the level of moulding automation, replace the labor with the casting molding machine, reduce the labor cost of the ...

Latest Posts

- الألغام وآلات البناء الاسمنت

- الكرة مطحنة المواد الجدول لوحة قطع غيار

- مطحنة الكرة مصنعين تاميل نادو

- تايلاند كسارات المخروط

- برومان الكسارة

- محطم خام الحديد الكبيرة ،

- شاكر الصانع اندونيسيا

- حجم الكرة السيراميك الكرة مطحنة

- بيع كربونات الكالسيوم المحجر

- سحق المعدات اللازورد

- مختبر مطحنة الكرة الصغيرة التكلفة

- عملية محطم

- ميكرومتر مطحنة نيجيريا

- الموارد المعدنية وغيرها من الموارد الطبيعية في زيمبابوي

- تشققت التكلفة

- Chemical Reagents For Flotation In Wastewater Treatment

- Stone Crushers And Different Varieties Related

- Hildelberg Tehnology Center Coal Mill

- How To Make A

- Semi Mechanised Brick Making Machines

- Processcrushing Process Of Recycling Aggregates

- Sbm Hydraulic Motor

- Separate The Ilimenite Gravity Spiral Chute For Mining Process

- Halite Ultra Grinding Ball Mill Pris

- Sediment Storage Bucket Hydrocyclone Slurry Mud Separation Desander

- The Volume Of Cement Industry Consumption Of Grinding Media

- Machine Roll Crusher Fb 0588076

- Large Bornite Peacock Ore Deposit

- Stone Crusher Pulverisers Ball Millrollers

- Feeding Machine Of Sand Making Line