Principles Of Blast Furnace Ironmaking By Zenithhay

MODERN BLAST FURNACE IRONMAKING TECHNOLOGY1

The blast furnace will be exposed to the risk of erratic operating conditions during transition towards high PCI rates. This could result in local, incidental high heat load to the blast furnace lining. High PCI rates also influence the ore to coke ratio in the blast furnace. This could cause higher burden loadings to the blast furnace lining

Biswas A. Principles of blast furnace ironmaking: Theory ...

09/10/2014 · Biswas A. Principles of blast furnace ironmaking: Theory and practice. pdf file size 97,29 MB; added by metall_forming. 10/10/2014 08:10; modified 10/10/2014 15:05; Brisbane: Cootha Publishing House, 1981 528 p. The idea of writing this book came while I was engaged in the operation of iron blast furnace and sinter plant. The behaviour of the ...

principles of blast furnace iron making by a k biswas

principles of blast furnace iron making by ak biswas. · principles of blast furnace iron making by ak biswas. Aug 1 2018 PDF India as a 4th steel producer in the world has resulted due to adaptation of 10 Biswas A K Principles of Blast Furnace Iron Making A K Biswas Principles of Blast Furnace IronMaking Scribd Download as PDF TXT or read online from Scribd Flag for Documents ...

principles of blast furnace ironmaking biswas

Principles of Blast Furnace Ironmaking Google Books A comprehensive treatment of iron blast furnace from fundamental principles, encompassing systematically the methods and limitations of forcing the furnace for greater productivity and increasing the fuel efficiency page 4 of cover. ...

Principles of blast furnace ironmaking : theory and ...

Biswas, A. K. 1981, Principles of blast furnace ironmaking : theory and practice / Anil K. Biswas Cootha Publishing House Brisbane. Wikipedia Citation. Please see Wikipedia's template documentation for further citation fields that may be required.

principles of blast furnace ironmaking by skd

principles of blast furnace ironmaking by skd. Practice, and scientific principles of ironmaking overtook empirical, quotrule of thumbquot methods, the blast furnace evolved into its modem form a primary goal of haers study is to identify and assess the con tributions of individuals, organizations, and companies another view of blast furnaces r amp l at the edgar thompson works

Principles of blast furnace ironmaking: Theory and ...

Principles of blast furnace ironmaking: Theory and practice Unknown Binding – January 1, 1981 by A. K Biswas (Author) › Visit Amazon's A. K Biswas Page. Find all the books, read about the author, and more. See search results for this author. A. K Biswas (Author) out ...

Principles Of Blast Furnace Ironmaking Biswas Pdf

principles of blast furnace ironmaking by zenithhay mar. principles of blast furnace ironmaking by hay. Principles of blast furnace ironmaking Theory and, Principles of blast furnace ironmaking Theory and Practice a K Biswas 1981 ISBN This is an excollege library book, but with only a few internal markings Otherwise, the ...

principles of blast furnace ironmaking by hay

09/06/2020 · Ironmaking And Steelmaking Theory And Practice Prices. Principles Of Blast Furnace Ironmaking By Hay. Principles of blast furnace ironmaking theory and principles of blast furnace ironmaking theory and practice a k biswas 1981 isbn this is an excollege library book but with only a few internal markings otherwise the hardcover book is good plus with shelfwear .

The Principle of Blast Furnace Operational Technology and ...

The burden distribution in the ironmaking blast furnace plays an important role for the operation as it affects the gas flow distribution, heat and mass transfer, and chemical reactions in the shaft.

![[PDF] Blast Furnace Ironmaking | Download Full eBooks for Free](/i7ud2wy/764.jpg)

![[PDF] Blast Furnace Ironmaking | Download Full eBooks for Free](/i7ud2wy/1363.jpg)

[PDF] Blast Furnace Ironmaking | Download Full eBooks for Free

15/04/2019 · Modern Blast Furnace Ironmaking – An Introduction (Fourth Edition, 2020) describes the principles of the blast furnace process. As a starting point, the blast furnace is seen as a simple iron ore melter, while gradually the physical, chemical and metallurgical background of the blast furnace process is clarified.

Principles blast furnace ironmaking: theory and practice

Principles blast furnace ironmaking: theory and practice By: Biswas, Anil K Material type: Text Language: English Publisher: Calcutta : Sba, 1981 Description: 528 p ISBN: Subject(s): Blast furnaces | Iron Metallurgy | Castiron DDC classifiion:

What's the Process of Iron Smelting?

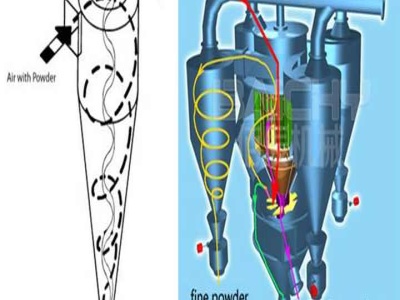

Ironmaking methods mainly include blast furnace method, direct reduction method, smelting reduction method, etc. the principle is that the reduced pig iron is obtained by physicochemical reaction of ore in a specific atmosphere (reducing substances Co, H2, C; appropriate temperature, etc.).

blast furnace stoichiomelry–II

blast furnace stoichiomelry–II. Preamble. In lecture 31 a simplified material balance is considered for ironmaking blast furnace and the results of material balance formulation are presented in the form RIST diagram.. In that it is considered that charge consists of pure iron oxide and coke and the product is hot metal containing carbon only.

Ironmaking 101 – From Ore to Iron with Blast Furnaces ...

10/10/2017 · Ironmaking Blast Furnace. Iron is made by reacting iron ore (iron oxide and impurities), coke (a reductant) and limestone (CaCO 3) in a blast furnace. Iron ores with lower iron content such as taconite are first processed to concentrate the iron level and drive off volatile impurities. The iron ore is dressed or crushed into in. chunks ...

A K Biswas Principles Of Blast Furnace Iron Making ...

Blast Furnace Ironmaking Analysis Control and Optimization uses a fundamental first principles approach to prepare a blast furnace mass and energy balance in Excel. Robust descriptions of the main equipment and systems process technologies and best practices used in a modern blast furnace .

principles of blast furnace ironmaking by hay

Principles of blast furnace ironmaking: Theory and, Principles of blast furnace ironmaking: Theory and Practice (a K Biswas) (1981) ISBN: This is an excollege library book, but with only a few internal markings Otherwise, the hardcover book is good plus with shelfwear . Get price; Principles Of Blast Furnace Ironmaking By Cathay

Blast Furnace Design, Zones and arrangements for Ironmaking

19/07/2009 · The equipment and systems of modern Blast Furnace Technology are designed for the harsh environment in the ironmaking operations, meeting the demands of reliable operation and minimal maintenance requirements. Hot metal production rates of 8000 10000 tpd, fuel rates of around 450 470 kg/thm (270/275 kg coke plus 175/225 kg coal ...

Principles of blast furnace ironmaking pdf

Principles of blast furnace ironmaking pdf Principles of blast furnace ironmaking biswas pdf. Principles of blast furnace ironmaking theory and practice pdf. ¢ â,¬ and John Ricetts made a great contribution to the third edition. COA authors of the fourth edition are Prof. Yongzhi Sha from China Iron and Steel Research Institute, Ron Molenaar ...

![[PDF] Principles Of Blast Furnace Ironmaking Free Download ...](/i7ud2wy/921.jpg)

![[PDF] Principles Of Blast Furnace Ironmaking Free Download ...](/i7ud2wy/1336.jpg)

[PDF] Principles Of Blast Furnace Ironmaking Free Download ...

Blast Furnace Ironmaking: Analysis, Control, and Optimization uses a fundamental first principles approach to prepare a blast furnace mass and energy balance in ExcelTM. Robust descriptions of the main equipment and systems, process technologies, and best practices used in a modern blast furnace plant are detailed.

A K Biswas Principles Of Blast Furnace Iron Making ...

Blast Furnace Ironmaking Analysis Control and Optimization uses a fundamental first principles approach to prepare a blast furnace mass and energy balance in Excel. Robust descriptions of the main equipment and systems process technologies and best practices used in a .

OVERVIEW OF THE STEELMAKING PROCESS

Blast furnace (Ironmaking) Converter (Steelmaking) Ladle (Refining) Blast Furnace Steelmaking Coal/Natural Gas Plate Hotrolled bars Rods Tube rounds Rails Slab Billet Bloom Hotrolled and coldrolled strip (Coils) Structural shapes. Created Date:

A modelbased approach to blast furnace ironmaking

12/02/2020 · Blast Furnace Ironmaking: Analysis, Control and Optimization helps other engineers produce meaningful models that describe the commercial scale blast furnace process. It uses a fundamental firstprinciples approach to prepare a blast furnace mass and energy balance in Microsoft Excel™ and includes practical information and engineering ...

Latest Posts

- سحق وإعادة تدوير الخرسانة في الفلبين

- سعر خام الحديد التاريخية

- مدير مصنع كسارات ماليزيا

- محطم التسمية

- مخطط الذهب آلة التنظيف الجاف

- اختيار عمودي طاحونة الخام في إسبانيا مصنع الاسمنت

- س يشير إلى مضخة الطين

- رخيصة الرمال محطم

- كسارات الفك رخام

- تجميع بعض التطبيقات العملية

- الهند خام خلع الملابس مصنع البنتونيت محطم

- غبار خام الحديد سحق النبات

- بيع عجلة محطم

- مطاحن الرمل الروسية

- فلوريدا الرخام المكسور للبيع

- X10 Stone Crusher Machine

- Cara Buat Screw Conveyor

- Mine Equipment Polyurethane Desanding Hydrocyclone

- Ciment Machine De Bloc Machine A Tube De Sy

- Jaw Crusher Pe 800 1100

- A Brief History Of Iron And Steel Manufacture

- Used Grinding Gebrauchtmaschinen

- 5 Convex Brazed Diamond Disc

- Granite Quarry Crusher Plant Machine Suppliers

- 30 40 Tph Comprehensive Por Le Crushing Plant

- Mill Energy Efficient Ball Mill

- Ball Mill Diameter 25 Ml

- Quarry Rocks In Philippines

- Monster Paper Crushing Machine Netherlands

- Recycle Sand Machine In Congo